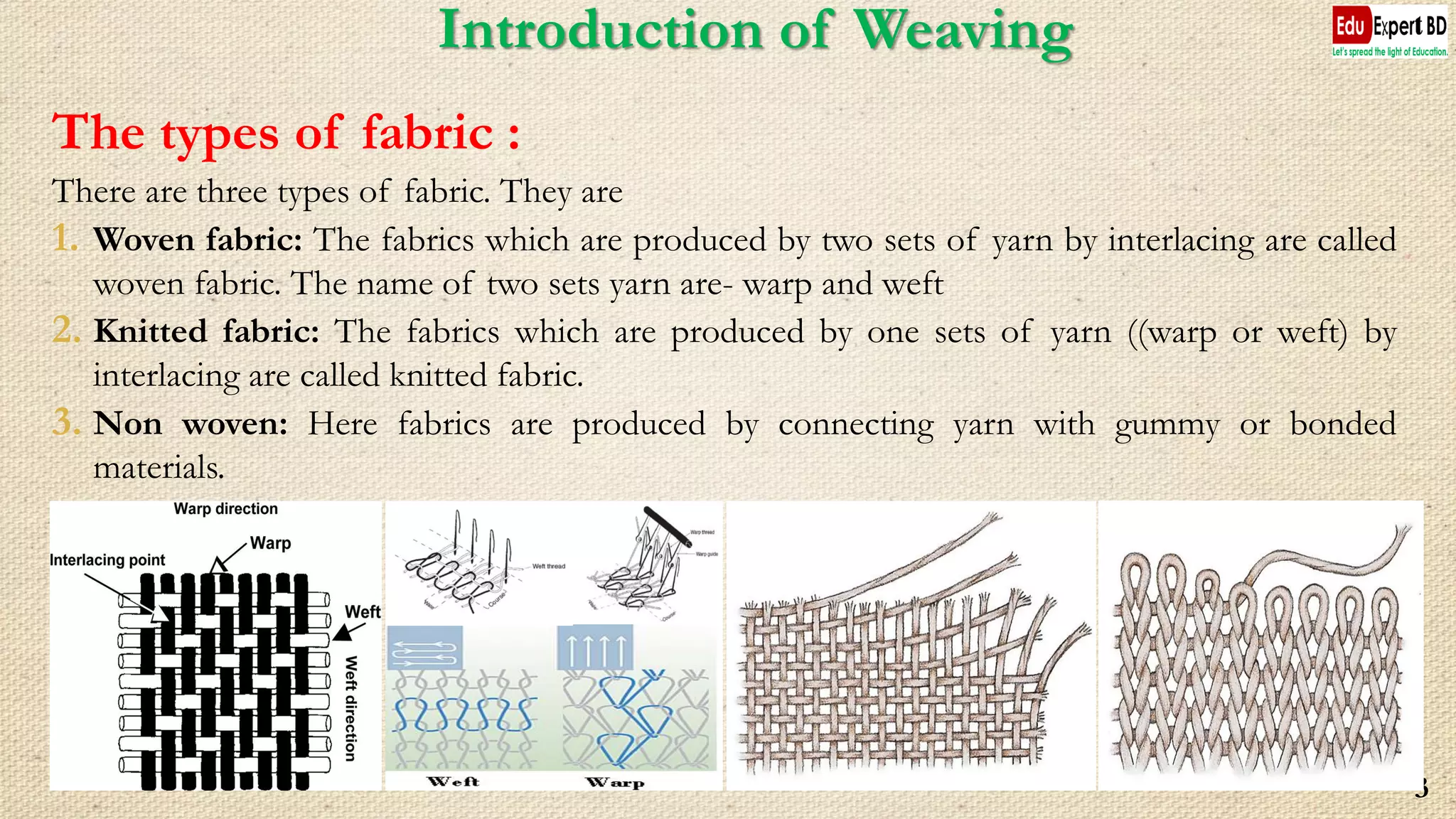

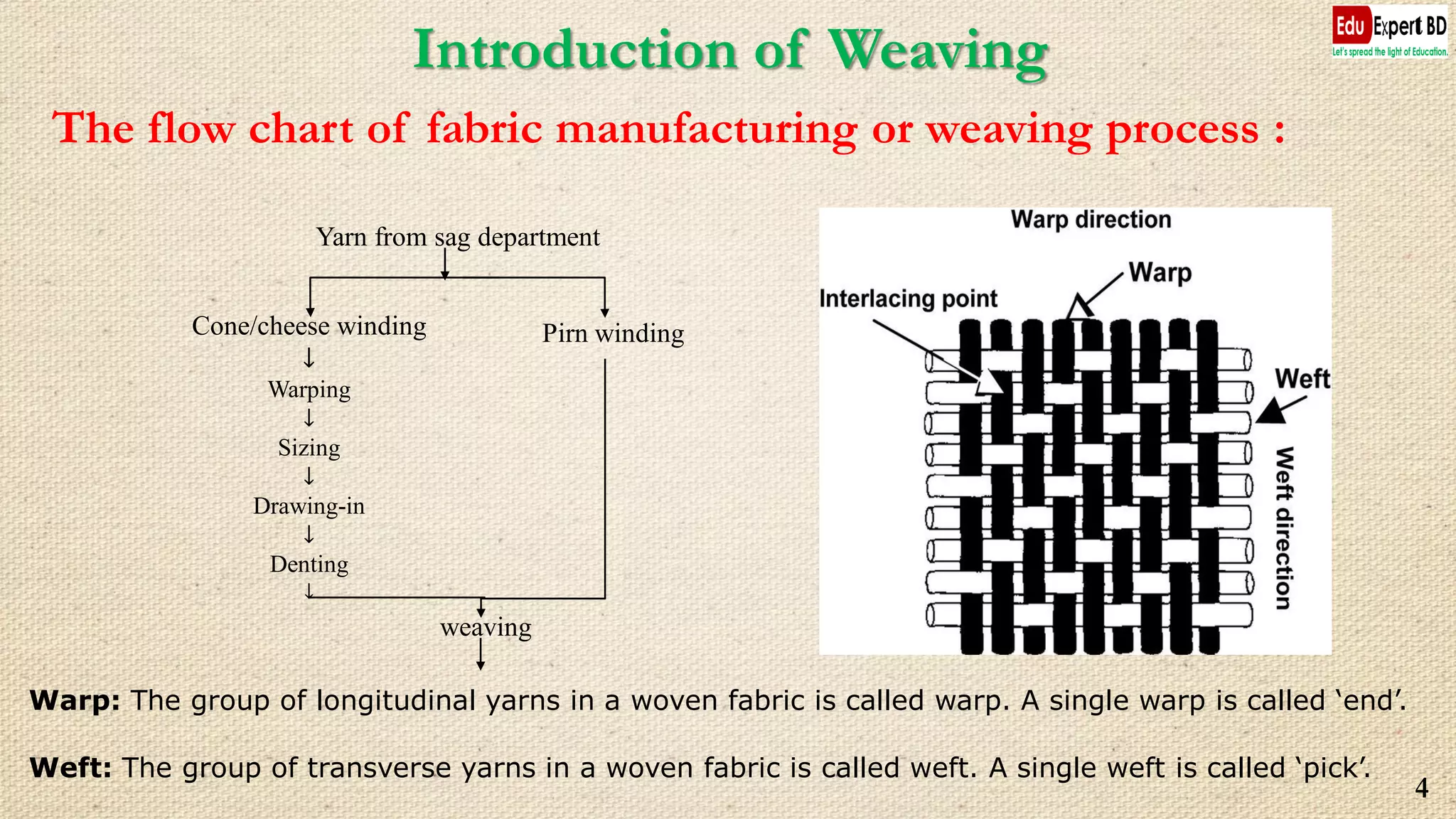

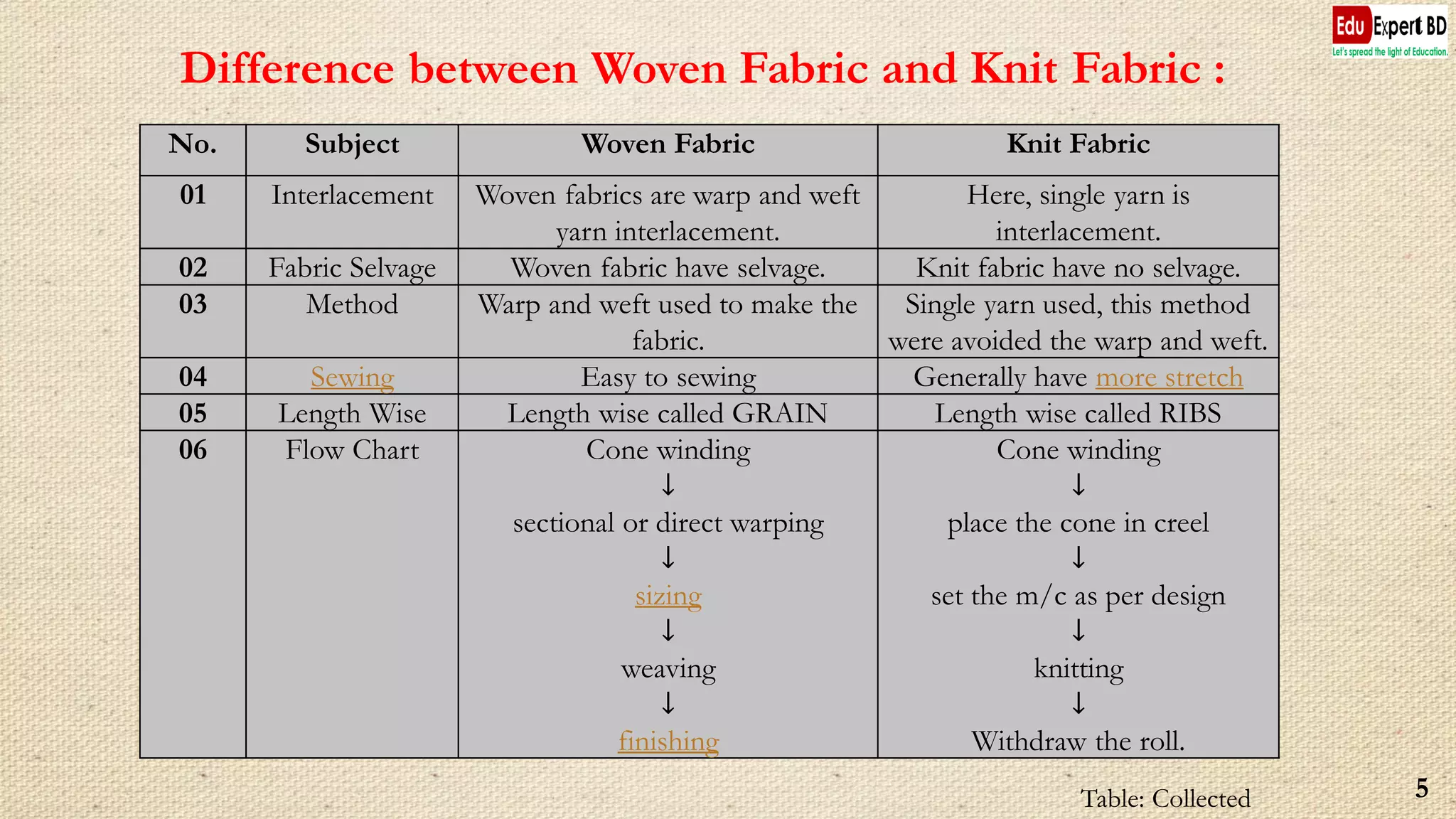

The document summarizes key aspects of textile engineering related to weaving. It discusses the three main types of fabrics - woven, knitted, and nonwoven - and describes the weaving process steps from winding the yarn to sizing and weaving. It also compares woven and knitted fabrics, explains why yarn preparation is necessary before weaving, outlines different types of looms including hand, power, automatic and shuttle-less looms, and describes the weaving processes of shedding, picking, and beat-up. The document was presented by Mazharul Islam from the Department of Wet Process Engineering at PTEC.