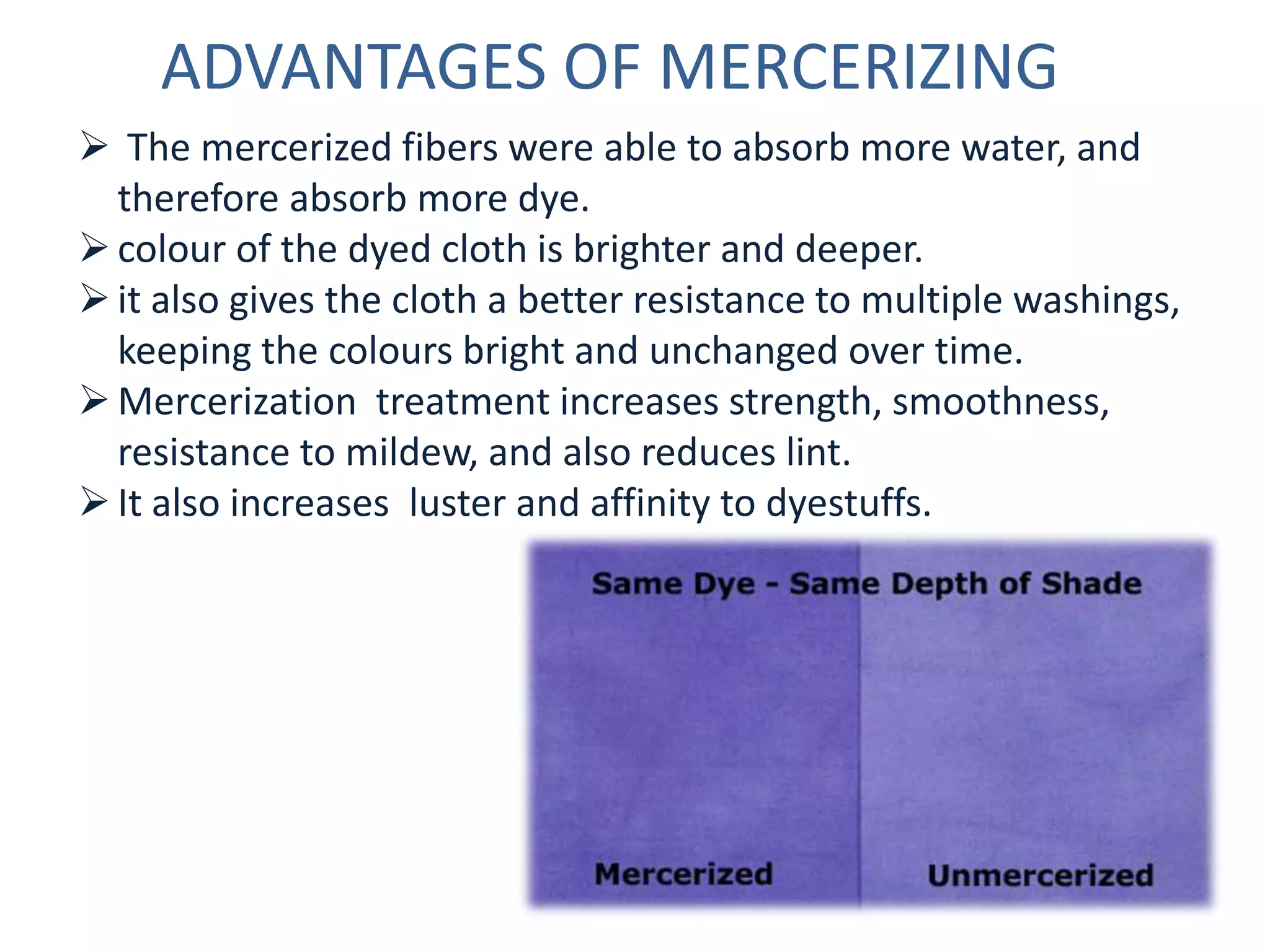

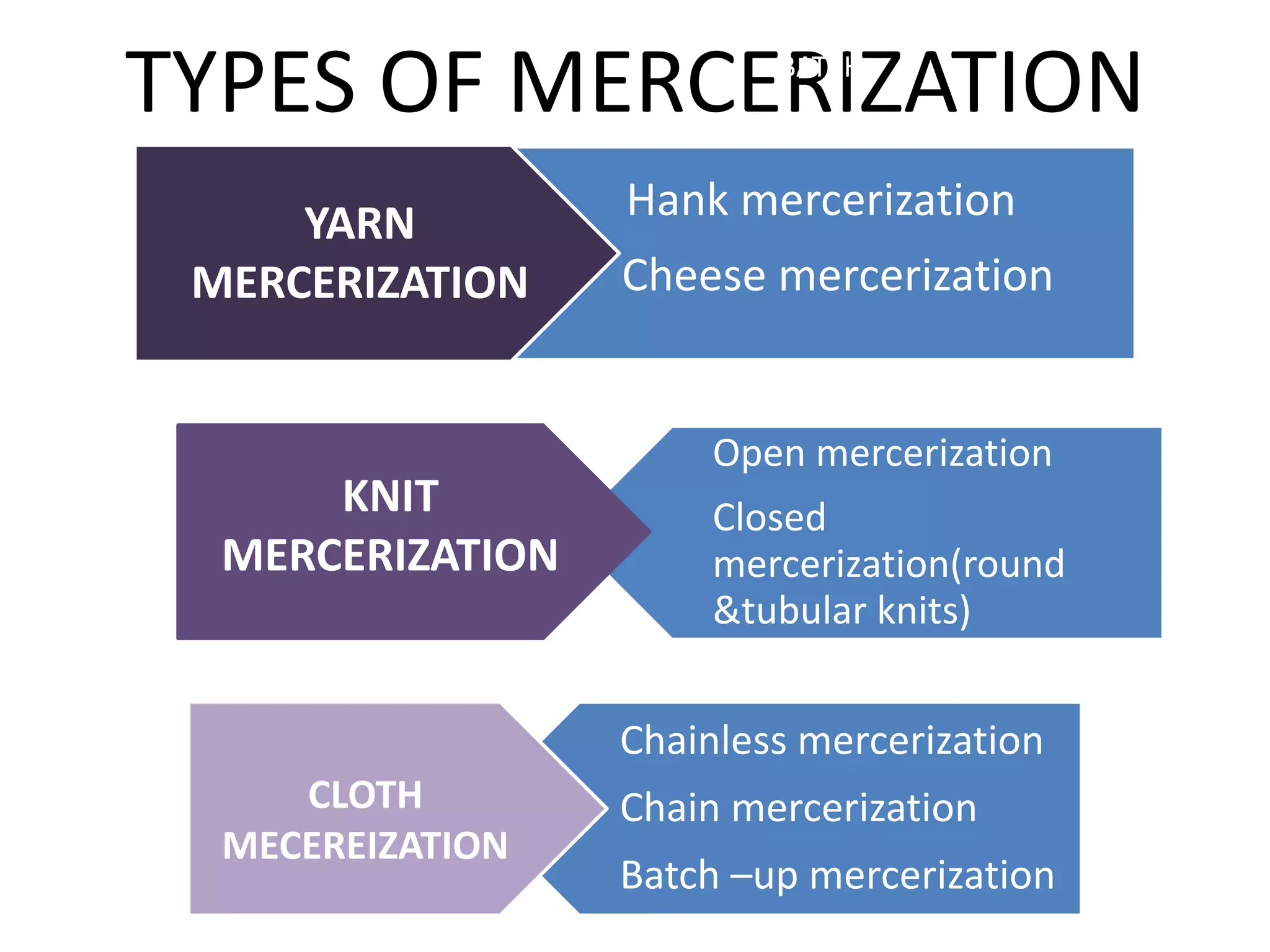

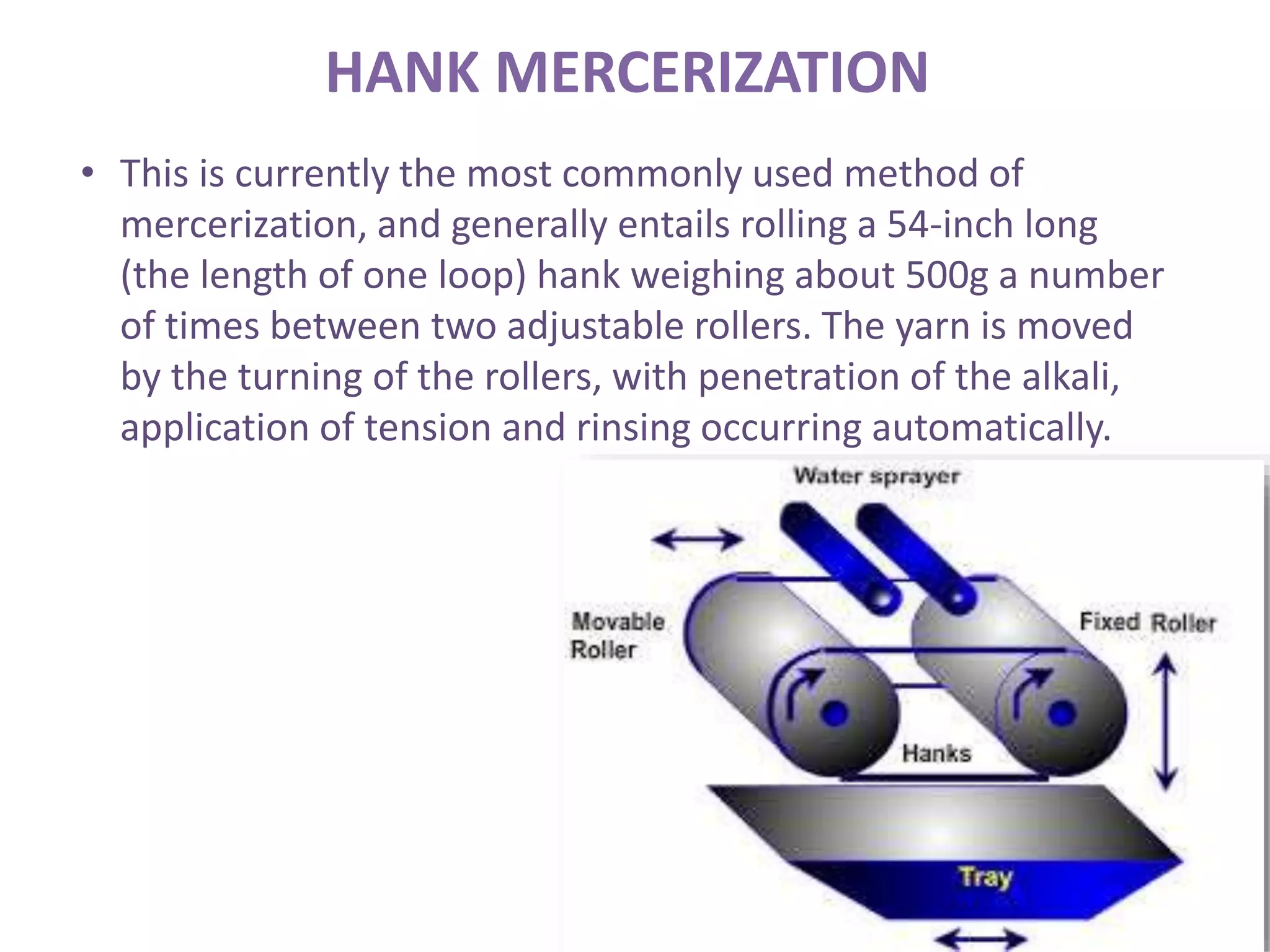

The document discusses the process of mercerizing cotton fabrics. Mercerizing involves treating cotton yarns or fabrics with a cold or hot solution of sodium hydroxide (caustic soda) under tension to improve properties like strength, luster, and dye affinity. Specifically, swelling the cotton fibers in the caustic soda solution changes their cross-sectional shape and increases luster when the tension is maintained during washing. There are different methods for mercerizing yarns, knits, and woven fabrics either as batches or continuously. The advantages of mercerizing include brighter dye colors, better color retention after washing, and increased strength, smoothness, and resistance to damage.