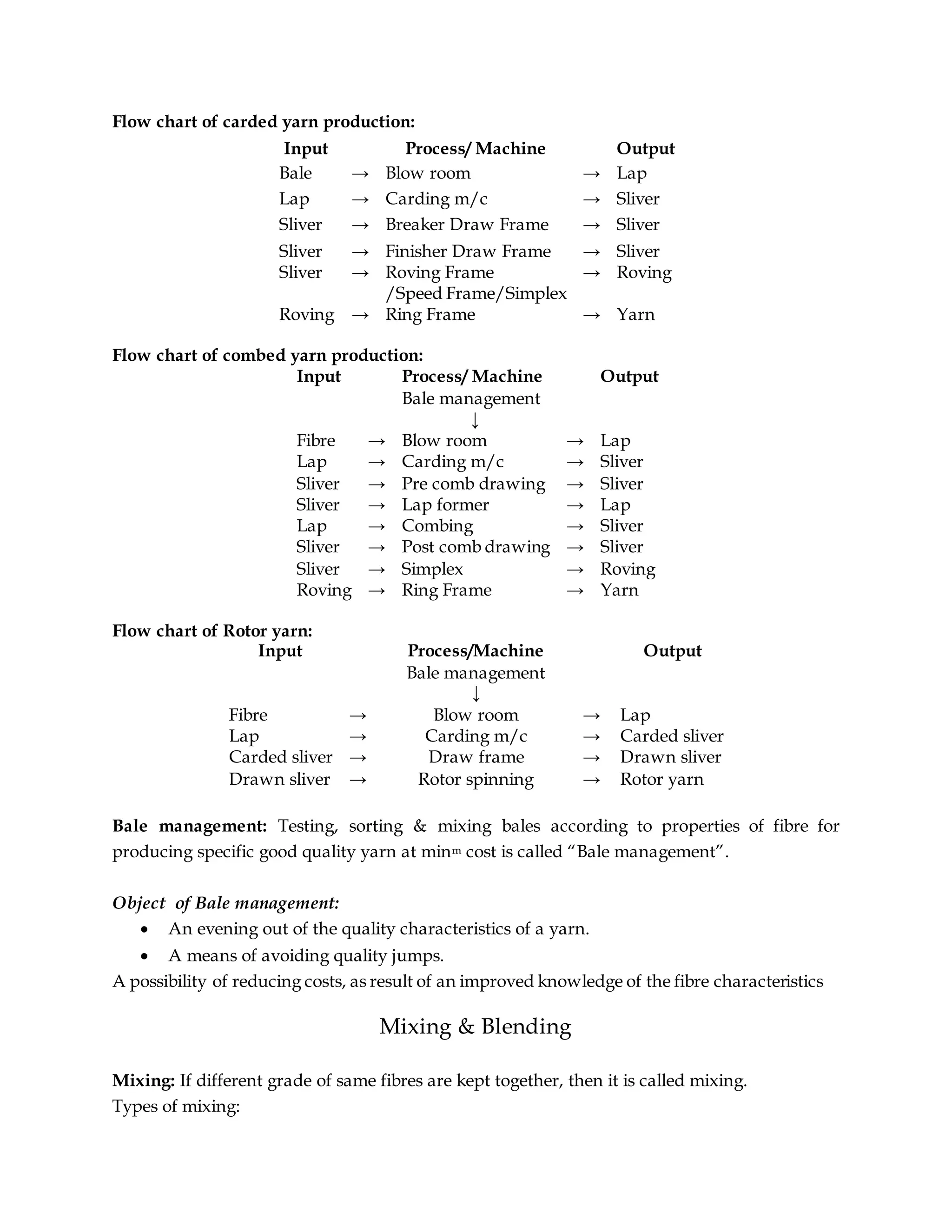

The document provides information on various processes involved in yarn production including carded yarn production, combed yarn production, rotor yarn production, and jute yarn manufacturing. It includes flow charts showing the input, process, machine, and output for each type of yarn production. It also describes processes like bale management, mixing, blending, ginning, blowroom, carding, draw frame, and jute processing steps.