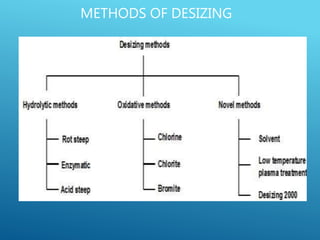

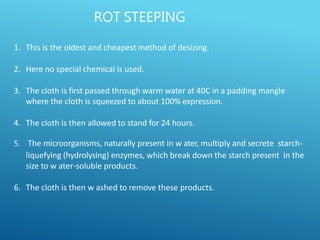

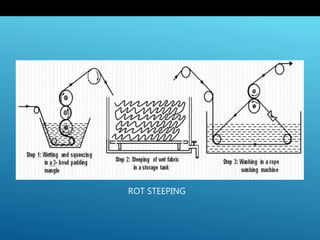

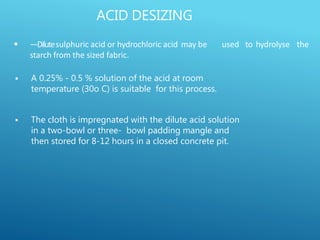

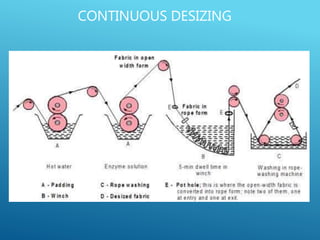

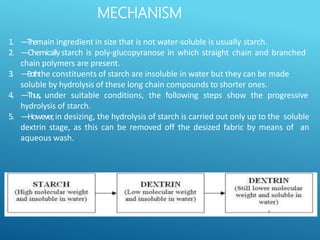

This document describes different methods of desizing fabrics. Desizing is necessary to remove starch-based sizing agents applied to warp yarns before weaving. The key methods discussed are hydrolytic desizing using water and microorganisms, acid desizing using dilute acid solutions, and enzymatic desizing using enzymes like malt extract. Oxidative desizing using oxidizing agents like sodium bromite is also covered, which oxidizes and depolymerizes the starch sizing agents. The document provides details on the processes and chemicals involved in each desizing method.