Quality control and testing are essential processes in the textile industry to ensure products meet specifications. There are several key steps:

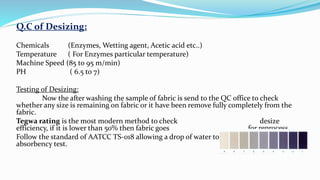

1) Pretreatment processes like singeing, desizing, bleaching, and mercerization are tested for parameters like chemical concentrations, temperatures, and absorbency.

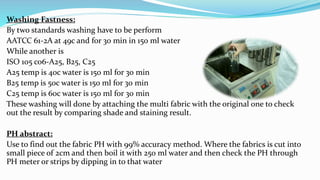

2) Dyeing and printing undergo physical tests for properties like colorfastness and chemical tests.

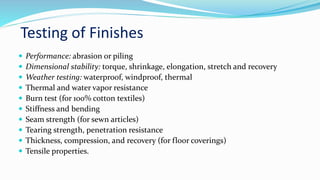

3) Finishing is tested for characteristics such as abrasion resistance, shrinkage, weather resistance, and burn resistance. Regular quality control and testing at all stages of production are vital for maintaining textile quality standards.