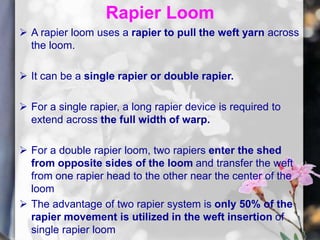

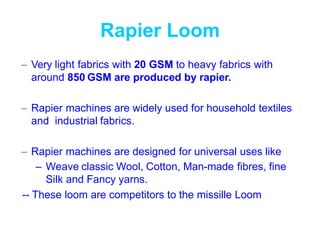

The document describes Abdullah Al Mahfuj's profile and a presentation on a rapier loom. It defines a rapier loom as using a rapier device to insert the weft yarn across the loom. There are two main types - single and double rapier looms. The presentation discusses the features, advantages and disadvantages of rapier looms, noting they can produce fancy fabrics but at a higher cost than other looms.