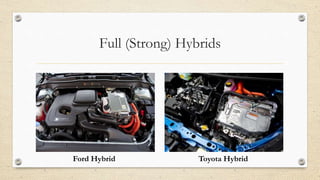

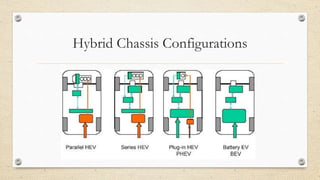

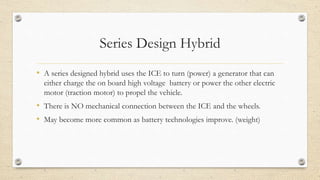

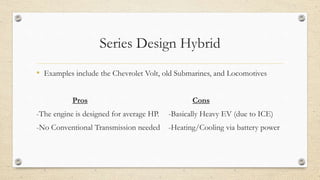

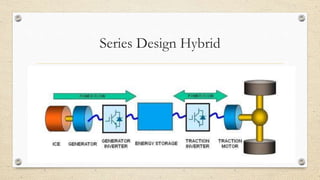

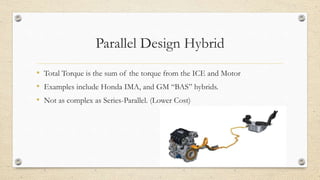

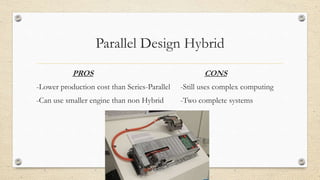

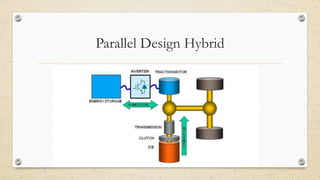

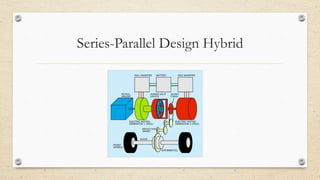

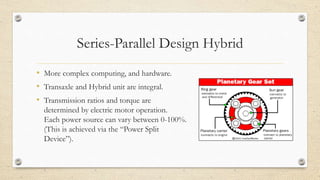

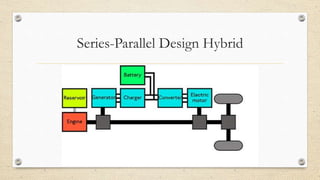

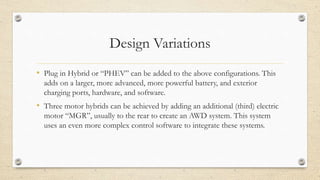

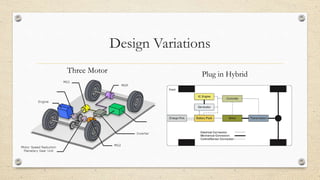

This document provides an overview of different types of hybrid vehicle systems. It discusses micro, mild, medium, full, and power hybrid categories based on the level of electric assistance. The main powertrain designs are series, parallel, and series-parallel. Series hybrids have no direct mechanical connection between the engine and wheels, parallel hybrids connect the engine and electric motor to the transmission, and series-parallel hybrids allow independent propulsion from either power source through a complex control system. The document provides examples and brief explanations of each hybrid type and design.