Embed presentation

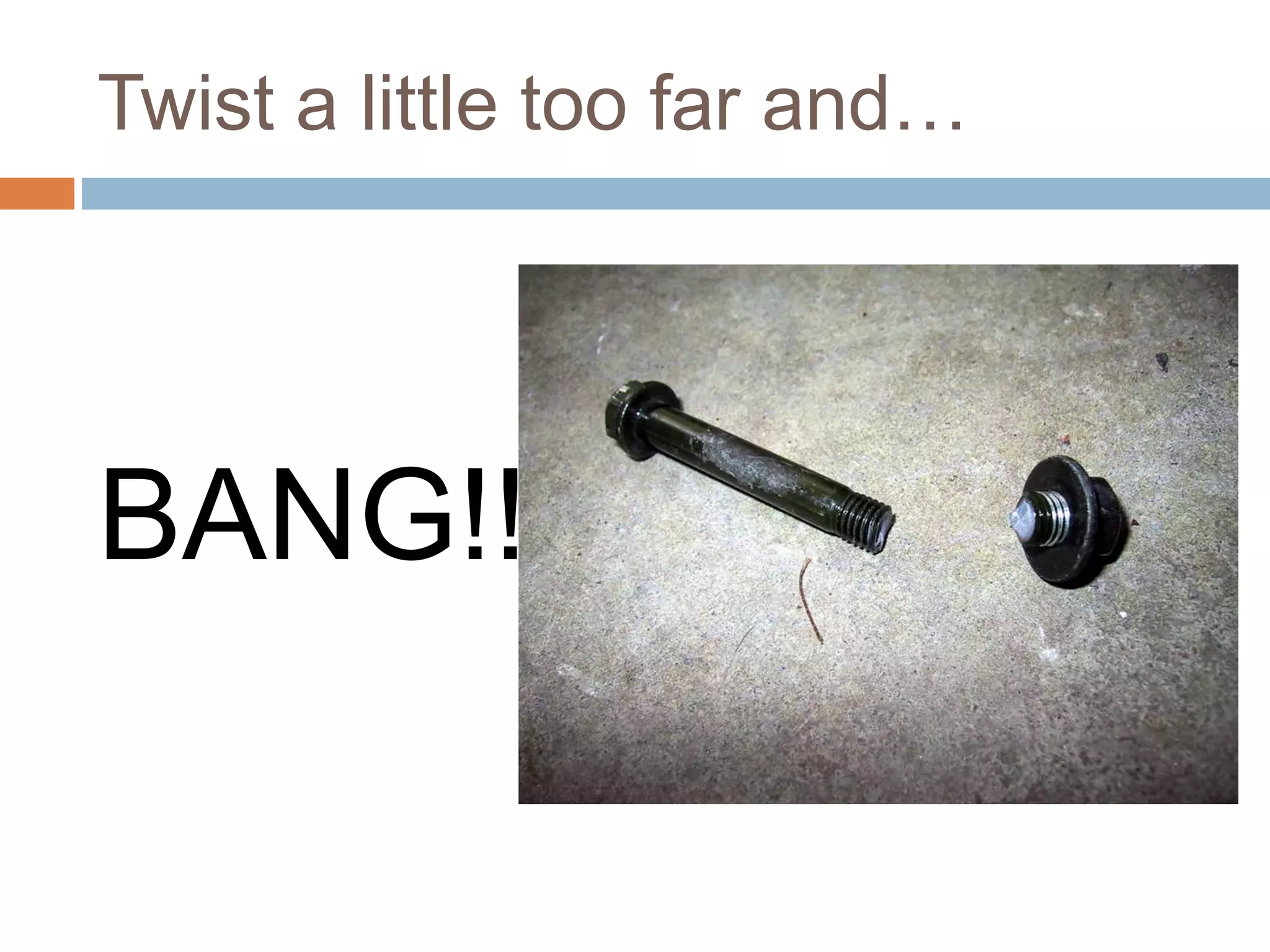

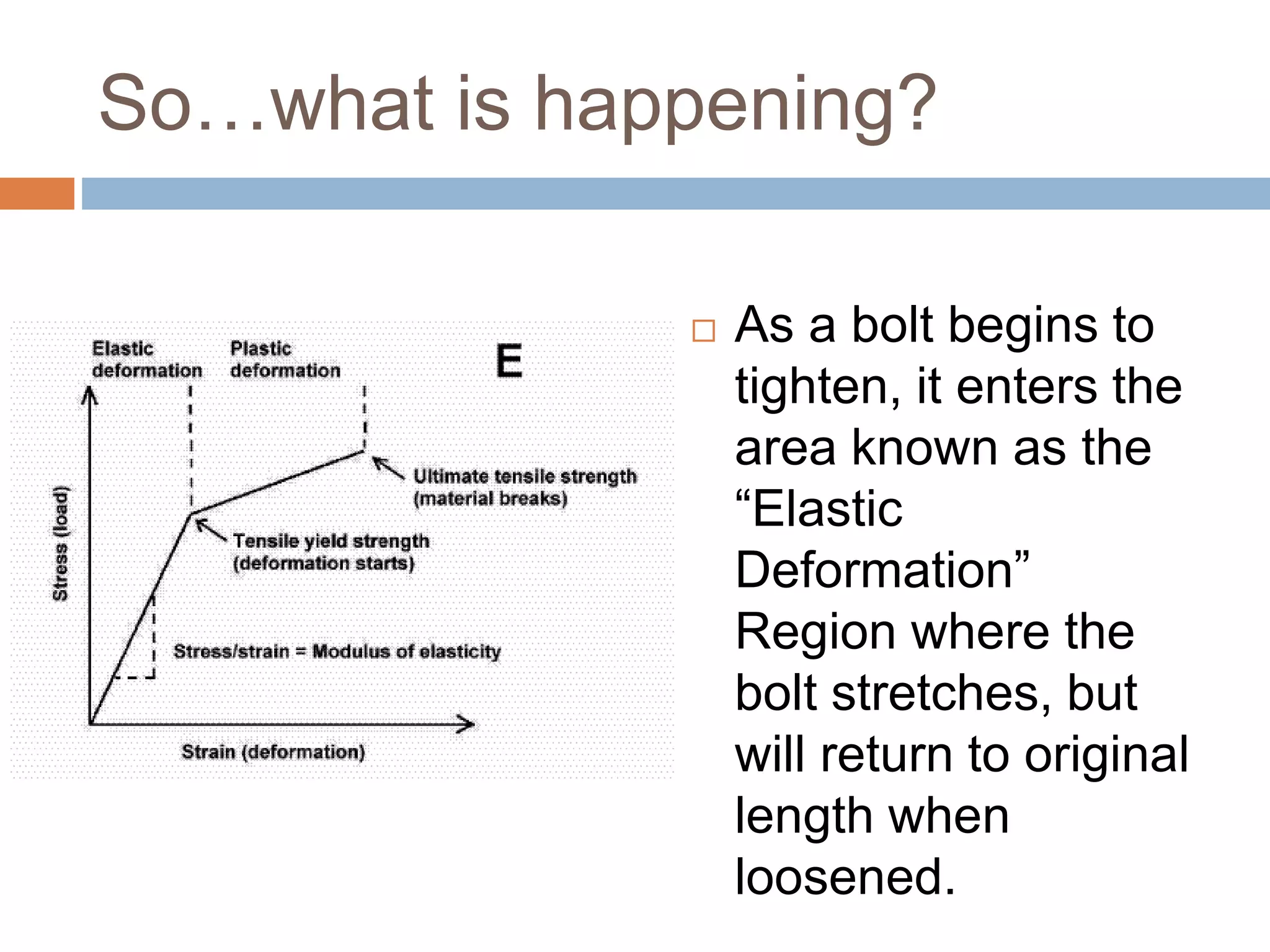

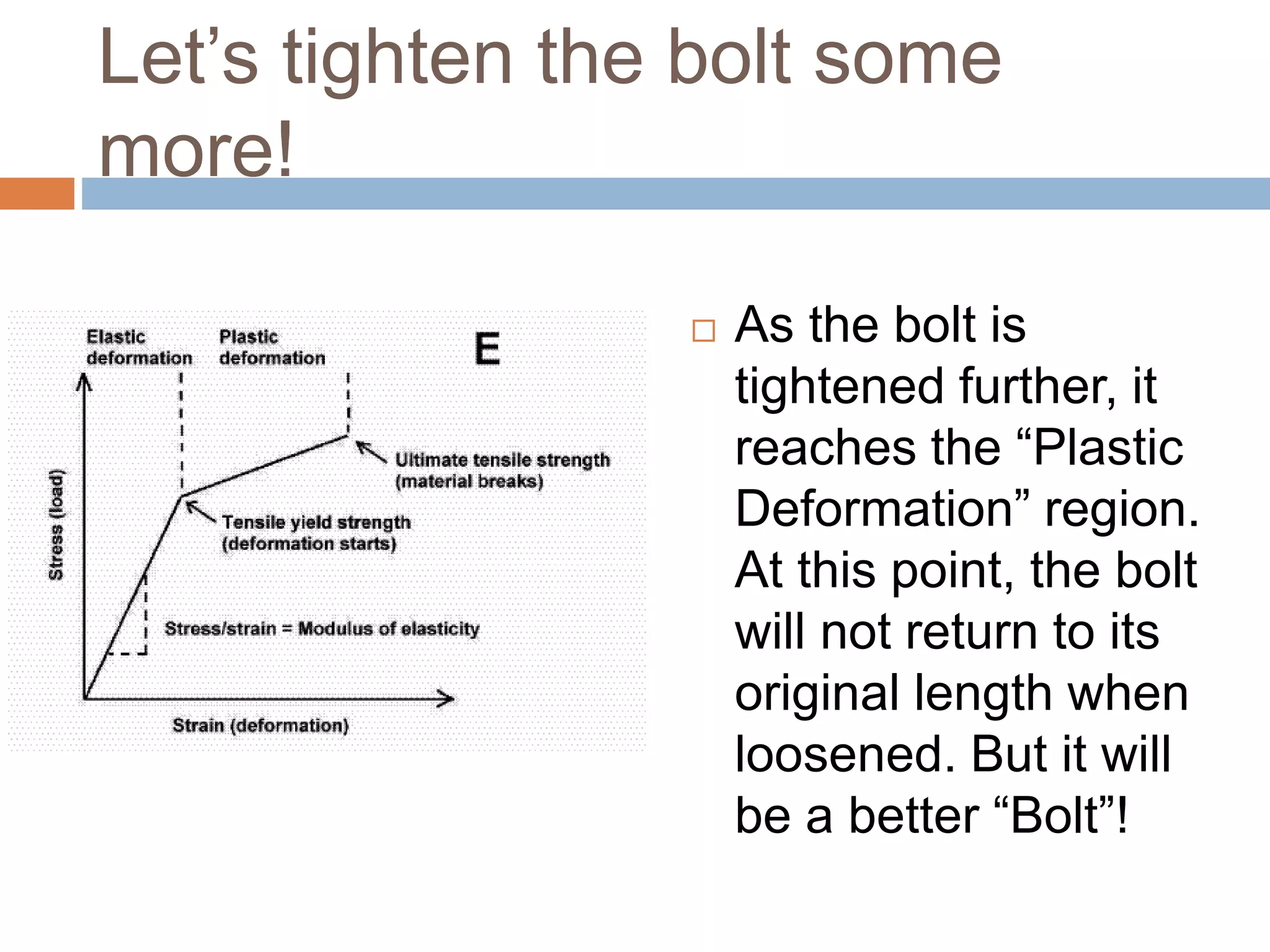

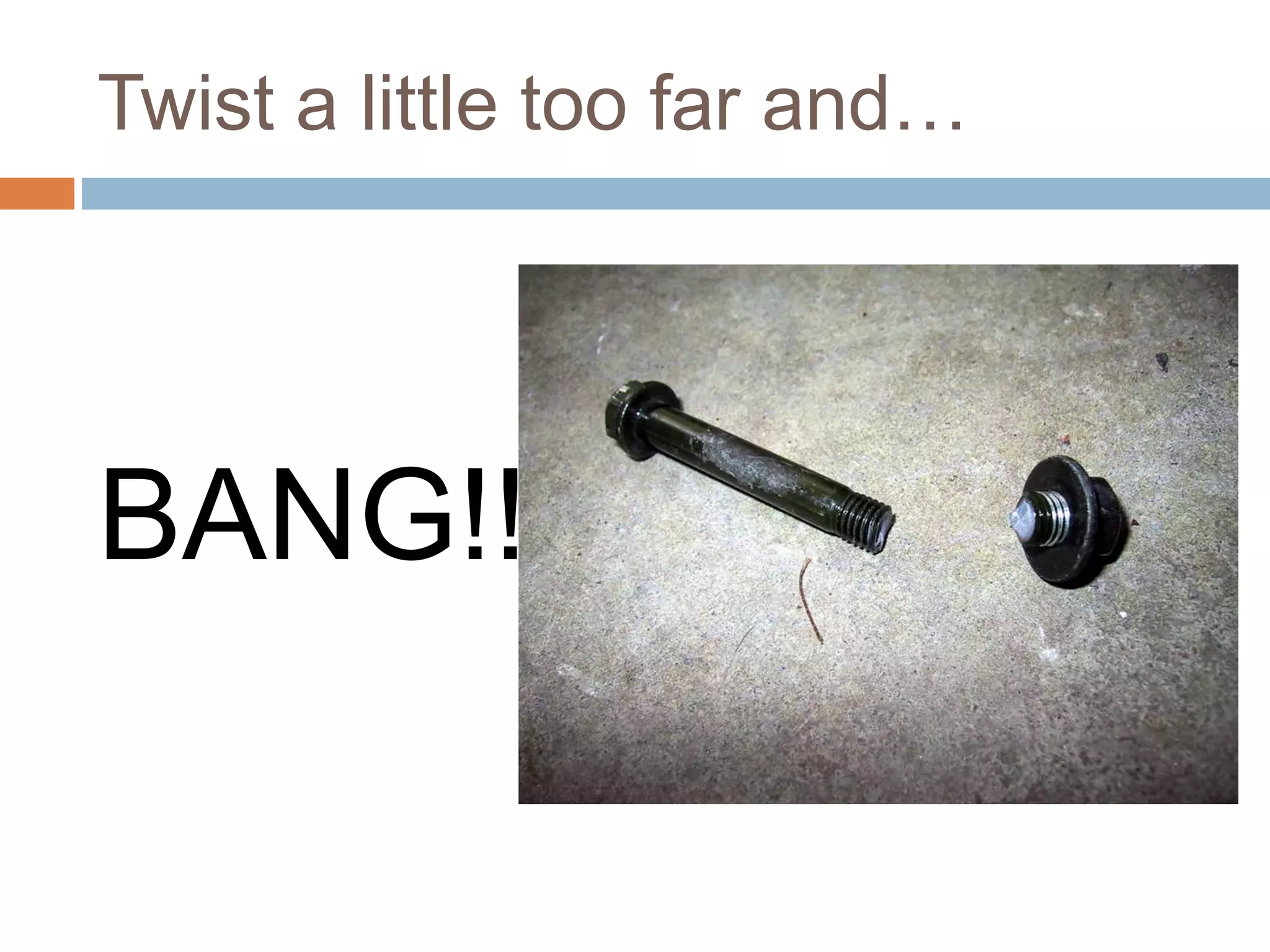

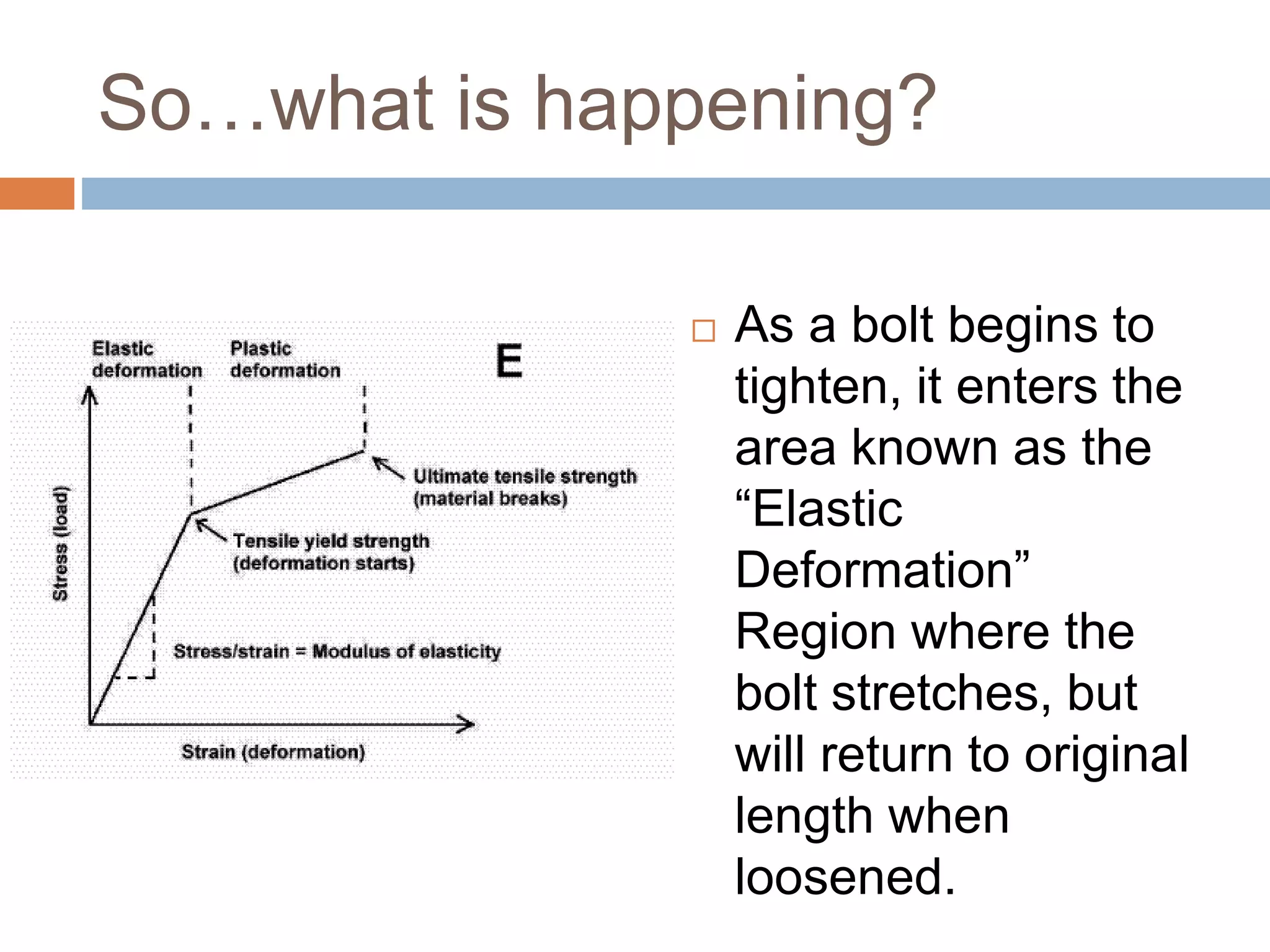

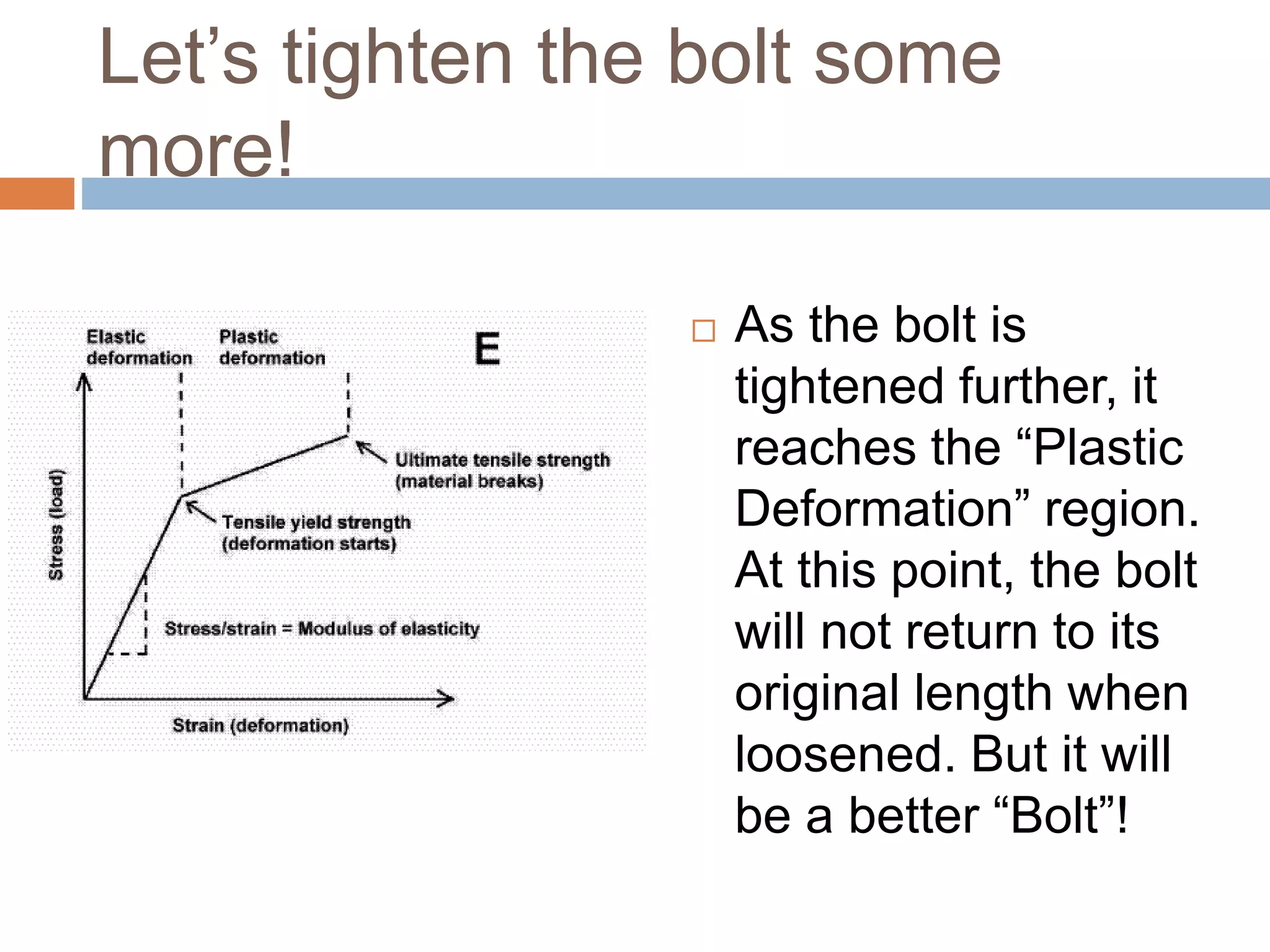

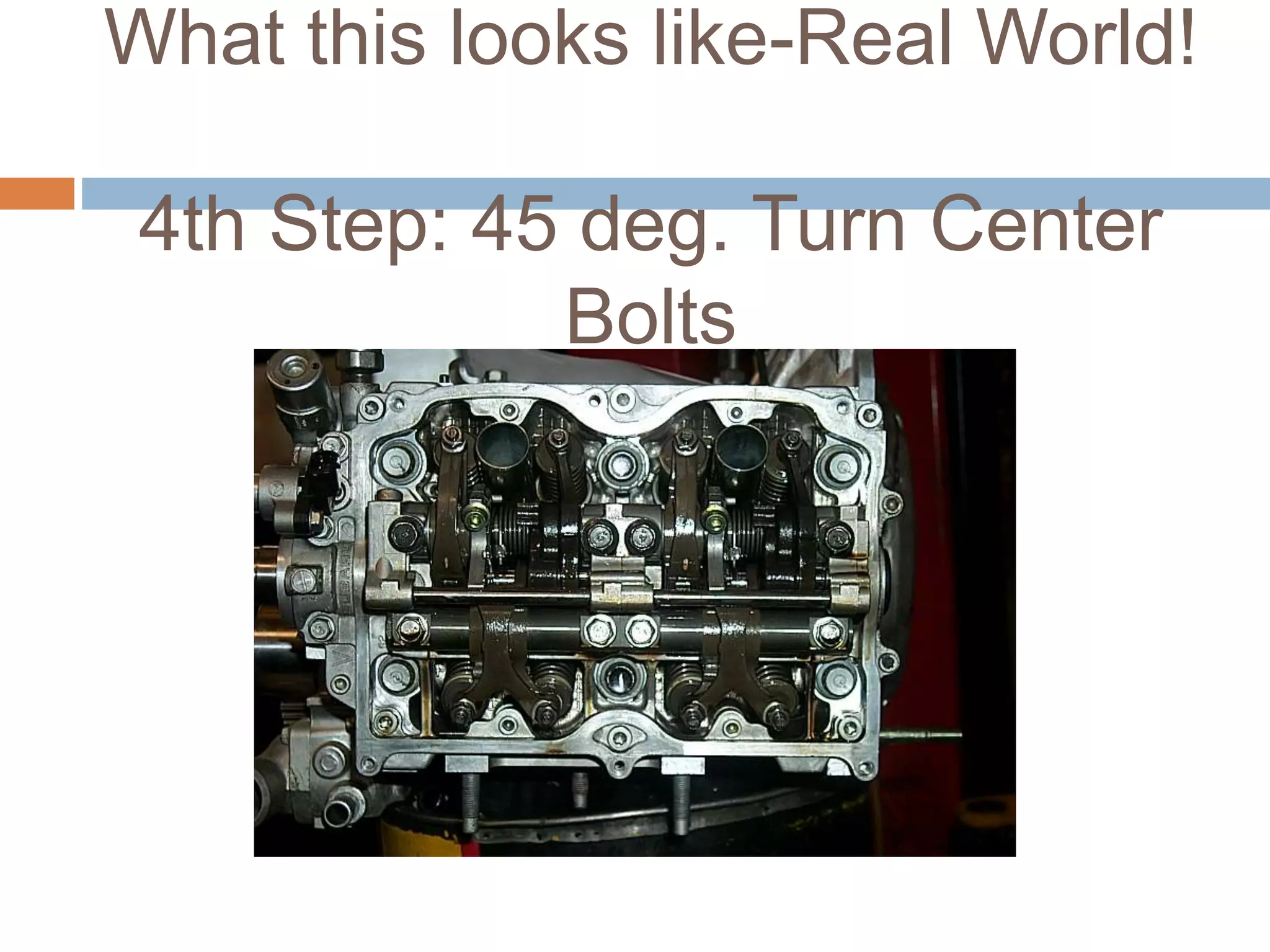

Torque-to-yield bolts are better than standard bolts for clamping because they provide more consistent torque over varying conditions and are designed to match the gasket and prevent failures. The bolts stretch into the plastic deformation region when tightened, meaning they will not loosen on their own. However, overtightening the bolts can cause them to snap, so it is important to follow the shop manual's instructions for the correct torque and tightening procedure.