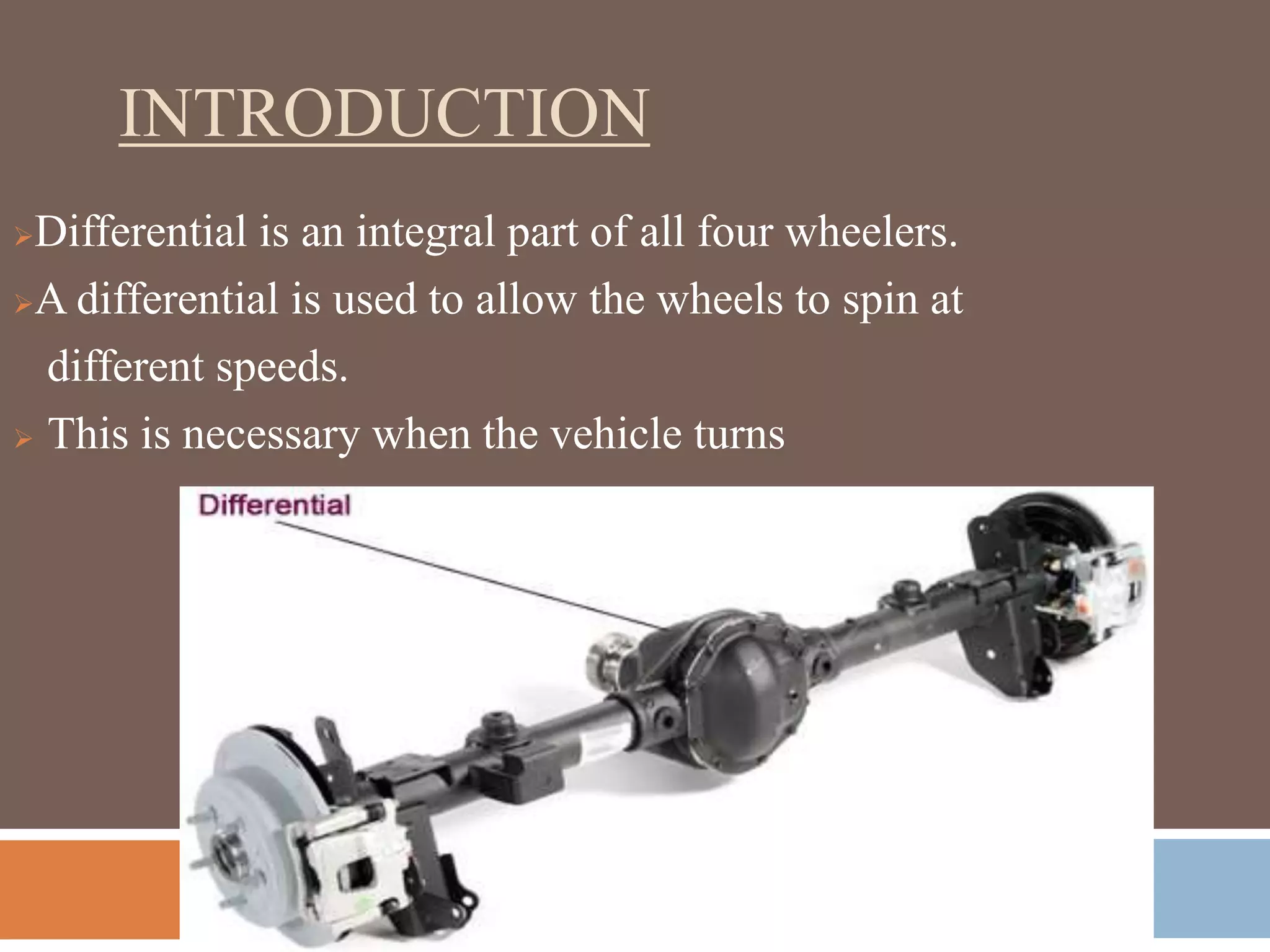

This technical seminar presentation summarizes the key components and functions of an automobile differential system. It discusses:

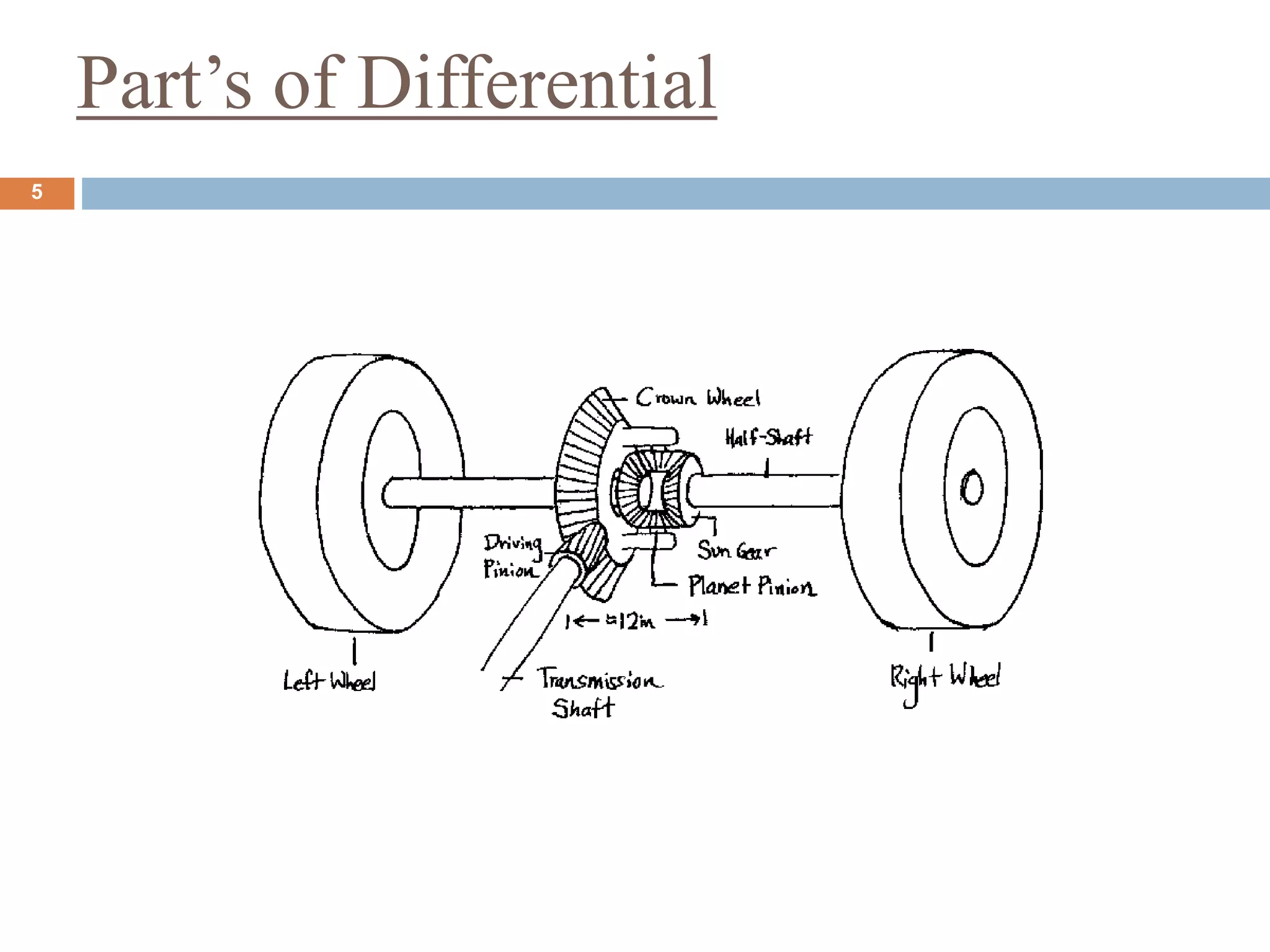

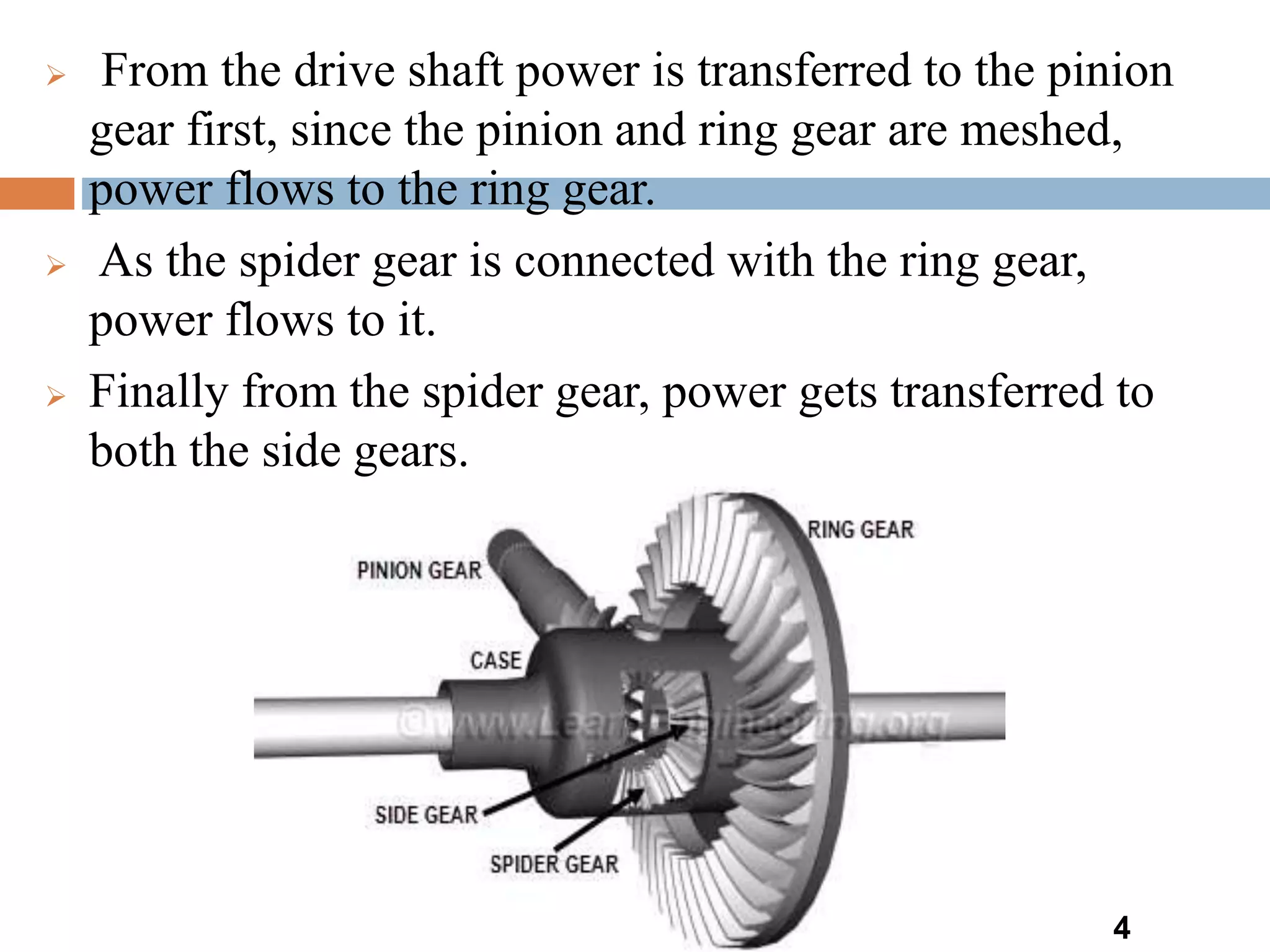

1) The main parts of a differential system including the pinion gear, ring gear, spider gears, differential case assembly, and rear drive axles.

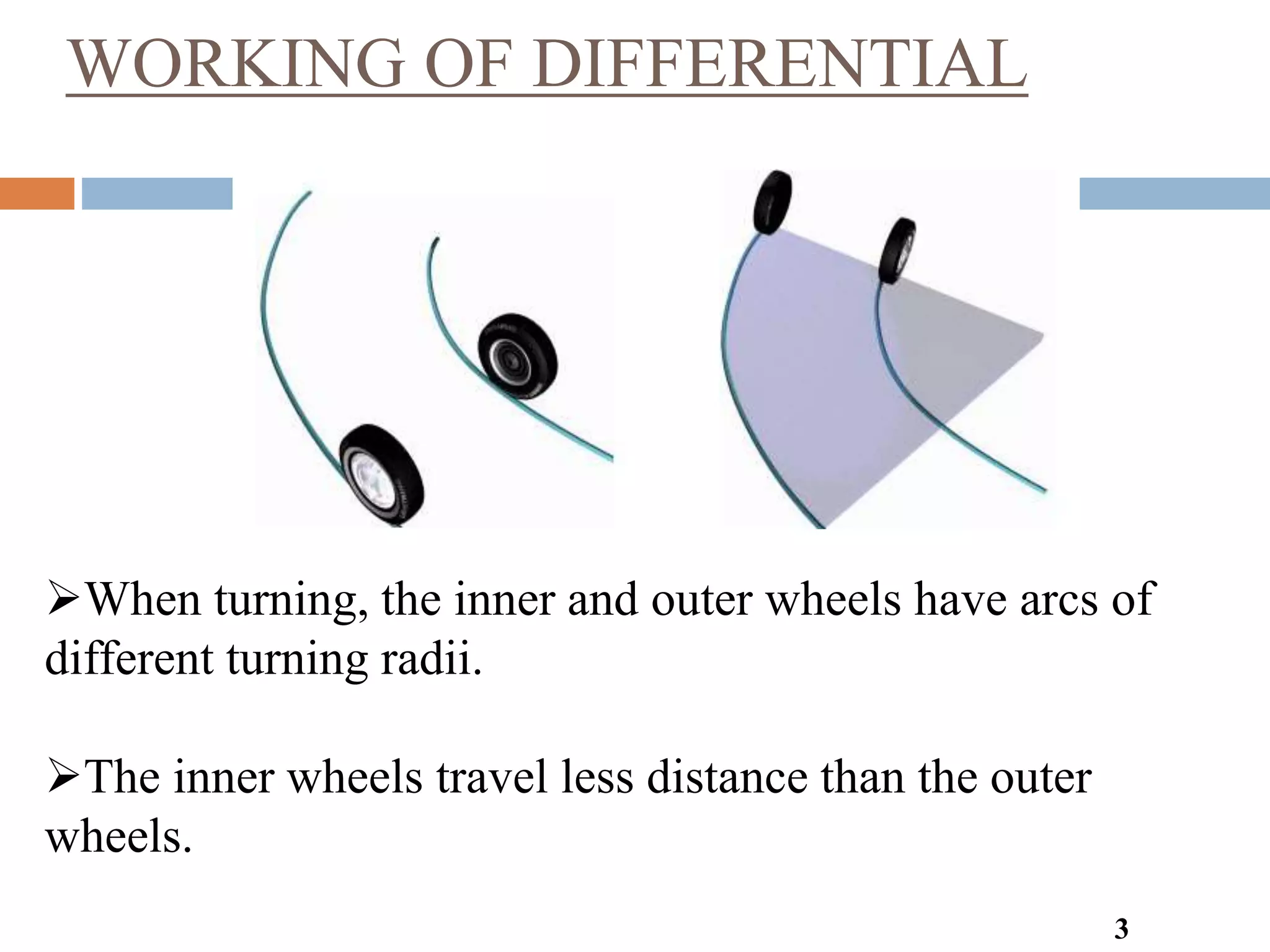

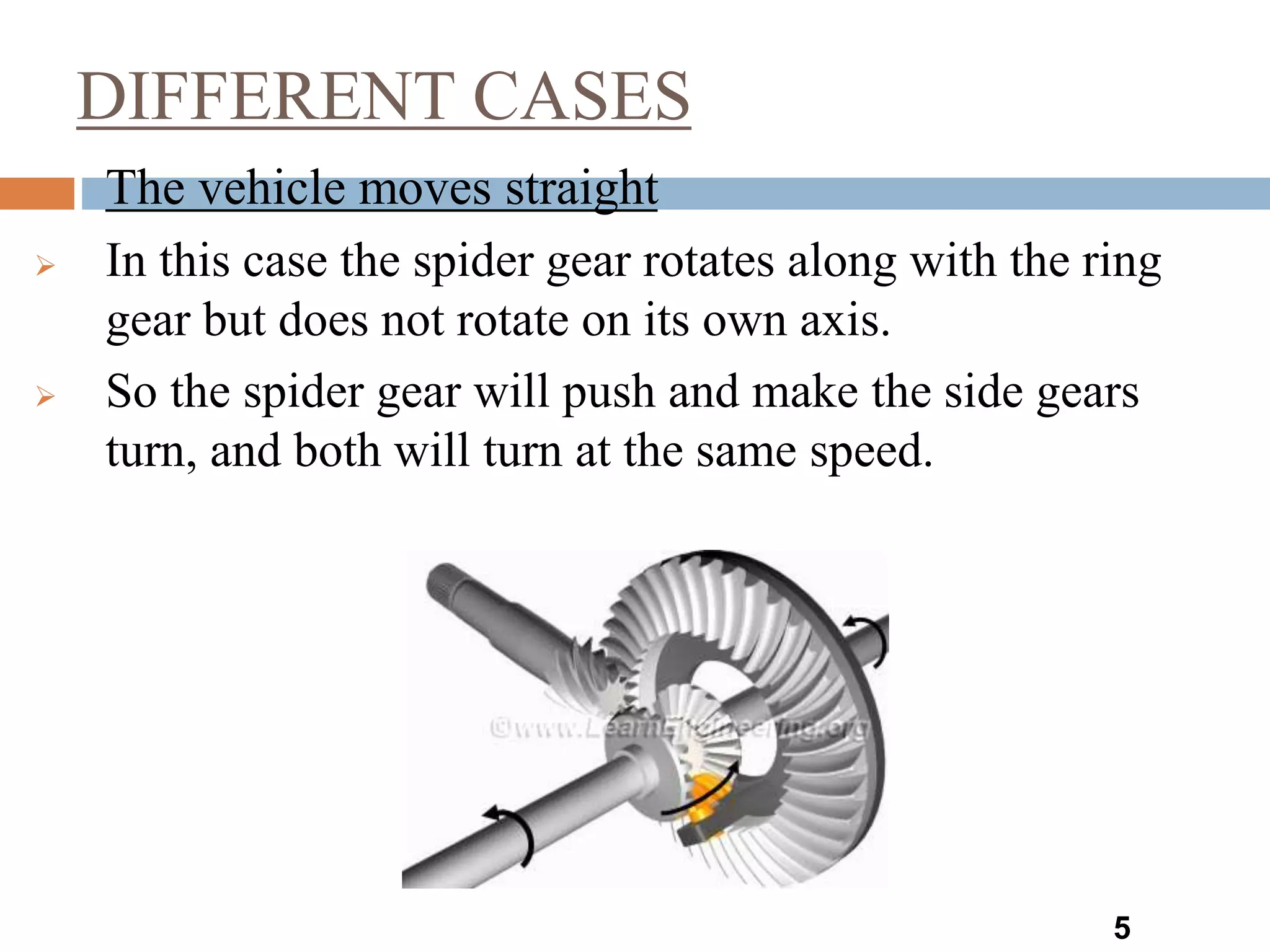

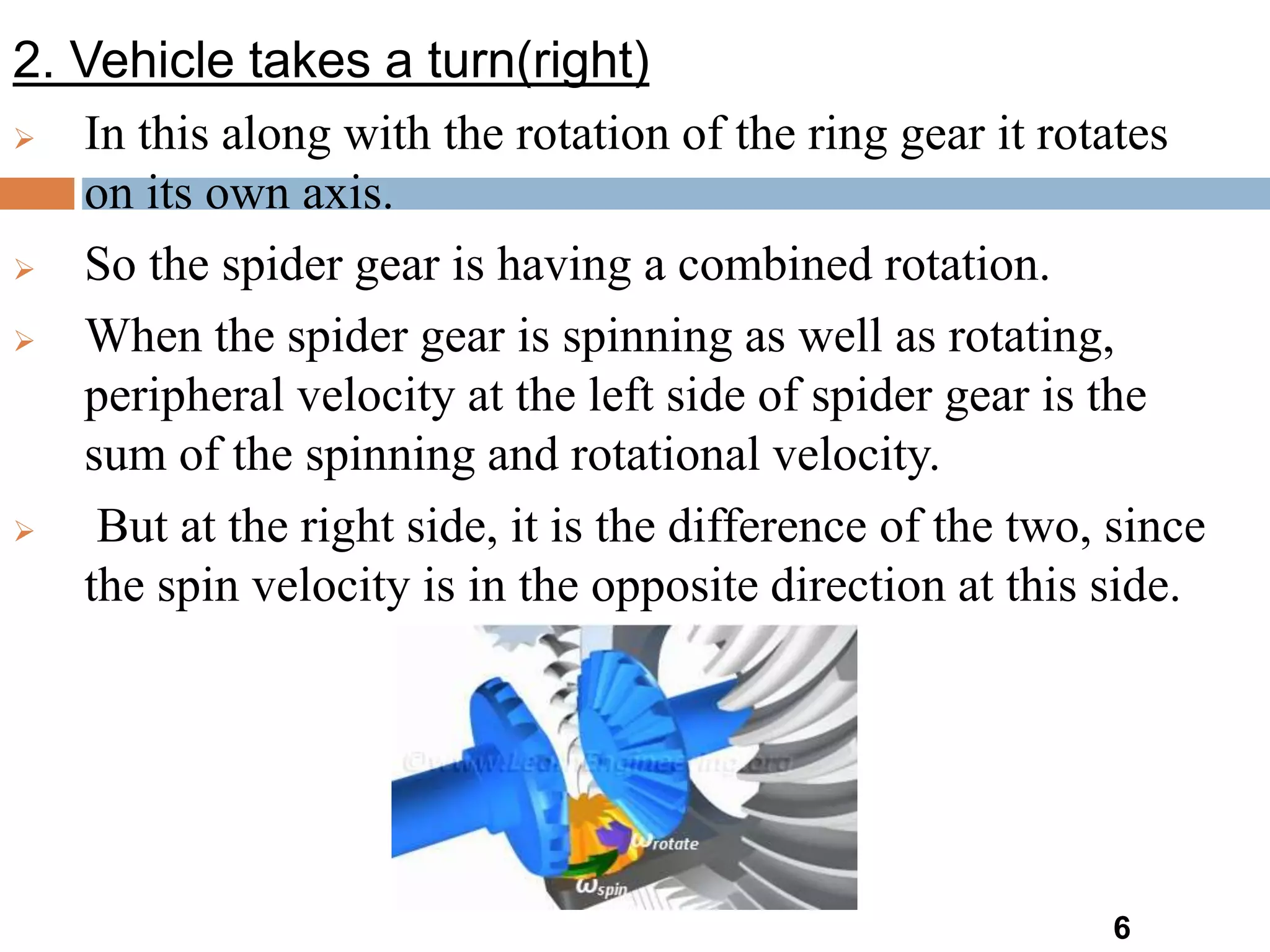

2) How differentials work by allowing the outer wheels to travel farther than the inner wheels when turning, while maintaining equal torque to both wheels.

3) The drawback of a standard open differential which can send all torque to a single slipping wheel, and how limited-slip differentials address this issue.