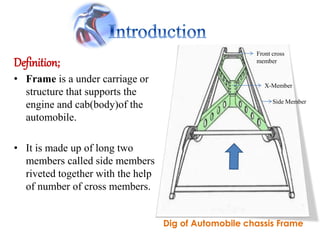

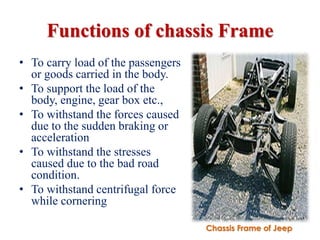

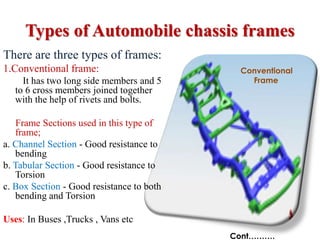

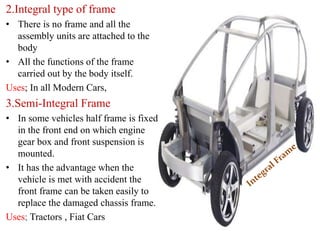

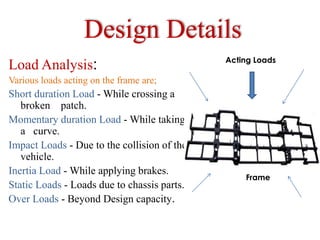

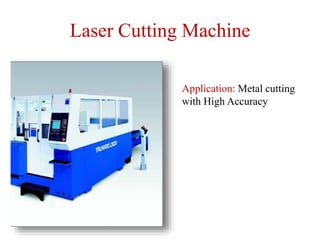

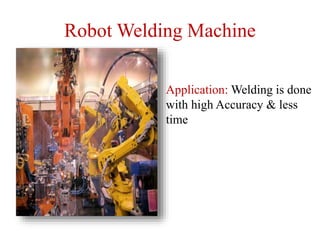

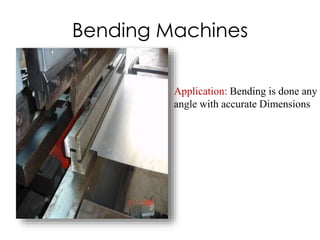

The document discusses automobile chassis frames. It defines a frame as the undercarriage or structure that supports the engine, cab, and body of a vehicle. There are three main types of frames: conventional frames with side members and cross members, integral frames where all components attach directly to the body, and semi-integral frames that have a partial front frame. The document outlines the functions of frames, provides examples of frame designs, and describes the materials, design considerations, and manufacturing processes involved in building frames, including cutting, bending, welding, and inspection stages. It concludes with details from a field visit to an automotive manufacturing plant.