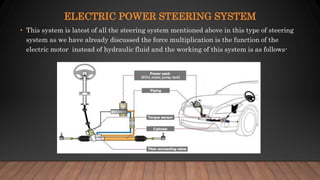

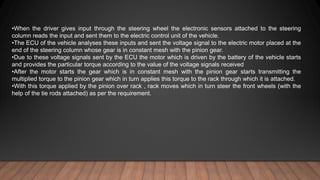

The document discusses power steering systems for automobiles. It begins by describing conventional steering systems and how power steering reduces the effort required to steer by multiplying the force applied through the steering wheel. Today, 80% of cars are equipped with power steering. It then discusses why power steering is needed for reasons like quick response time, reducing steering fatigue, controlling bump steer, and improving returnability. The document outlines the three main types of power steering systems - hydraulic, electro-hydraulic, and electronic - and describes the key components and working of each type.