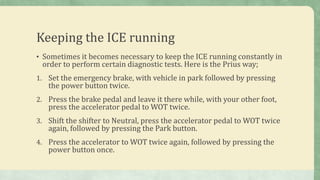

Hybrid vehicles use different engine cycles like the Atkinson cycle to improve efficiency over traditional Otto cycle engines. The Atkinson cycle provides higher efficiency through a smaller compression ratio and longer power stroke, though it sacrifices power. This lost power can be made up through an electric motor in a hybrid system. Modern hybrids also use variable valve timing and cylinder deactivation to further improve efficiency. During diagnosis of hybrid engines, procedures need to account for the idle-stop feature and electric motor involvement in engine operation to properly diagnose engine-related issues.