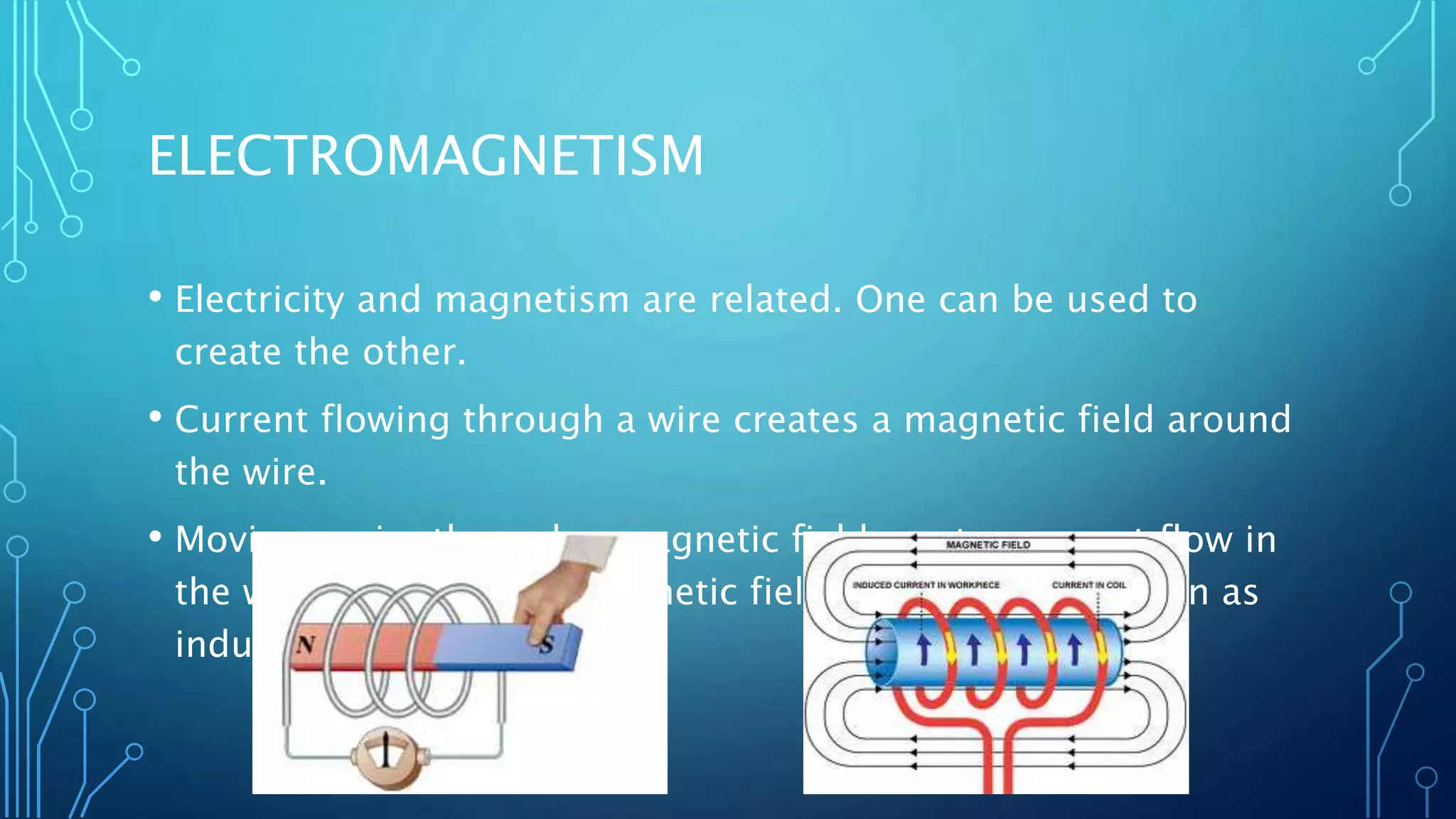

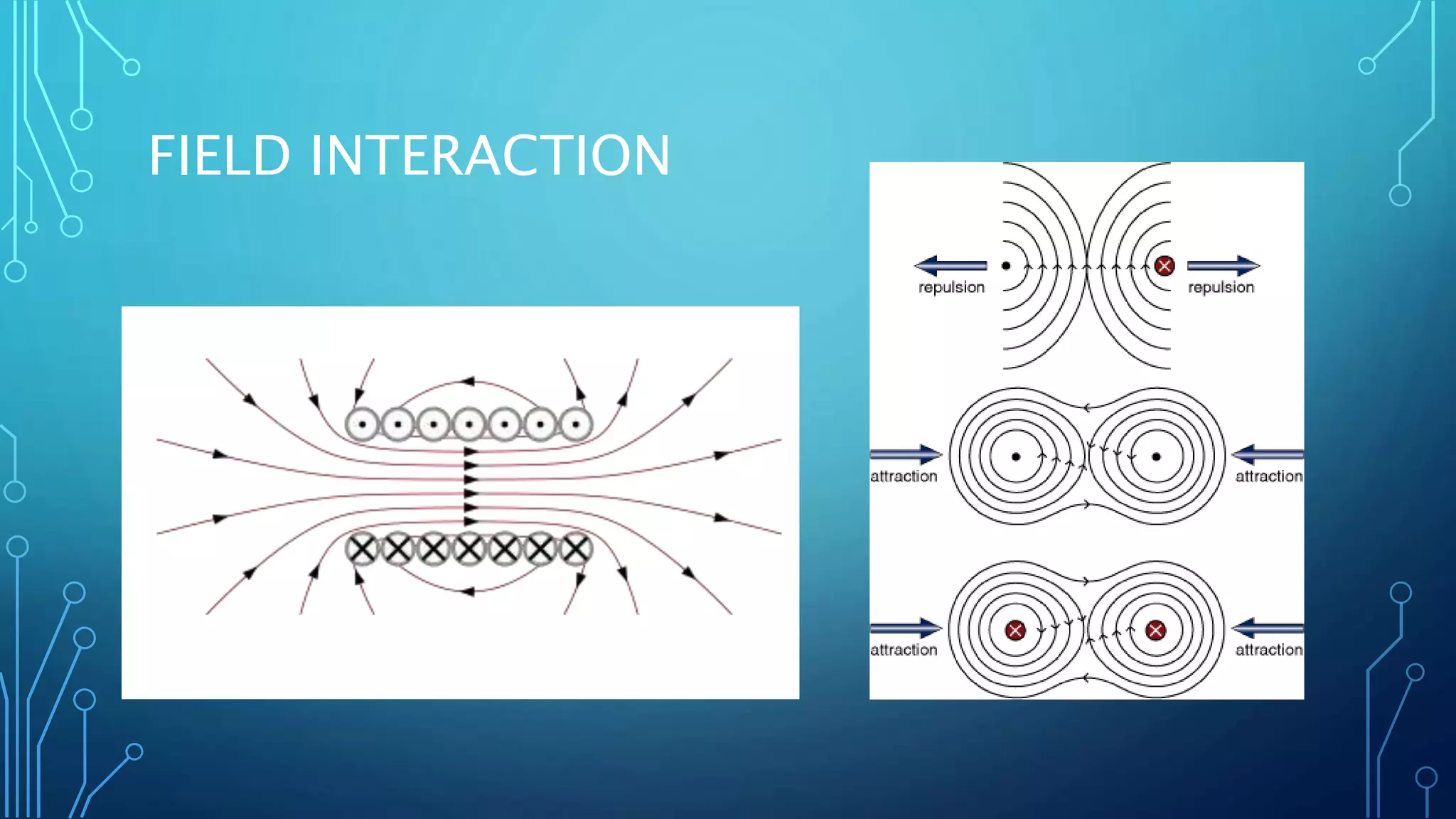

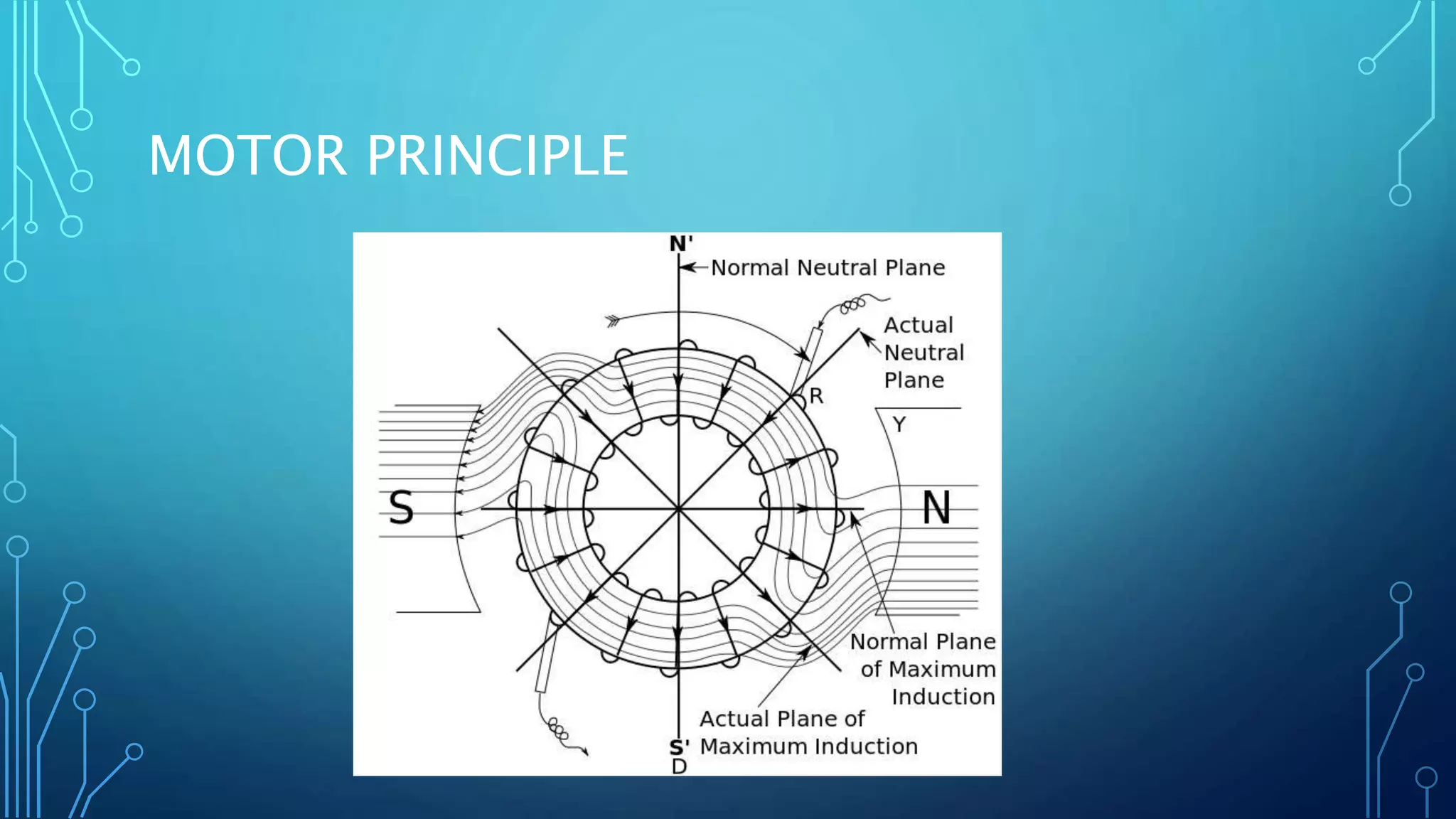

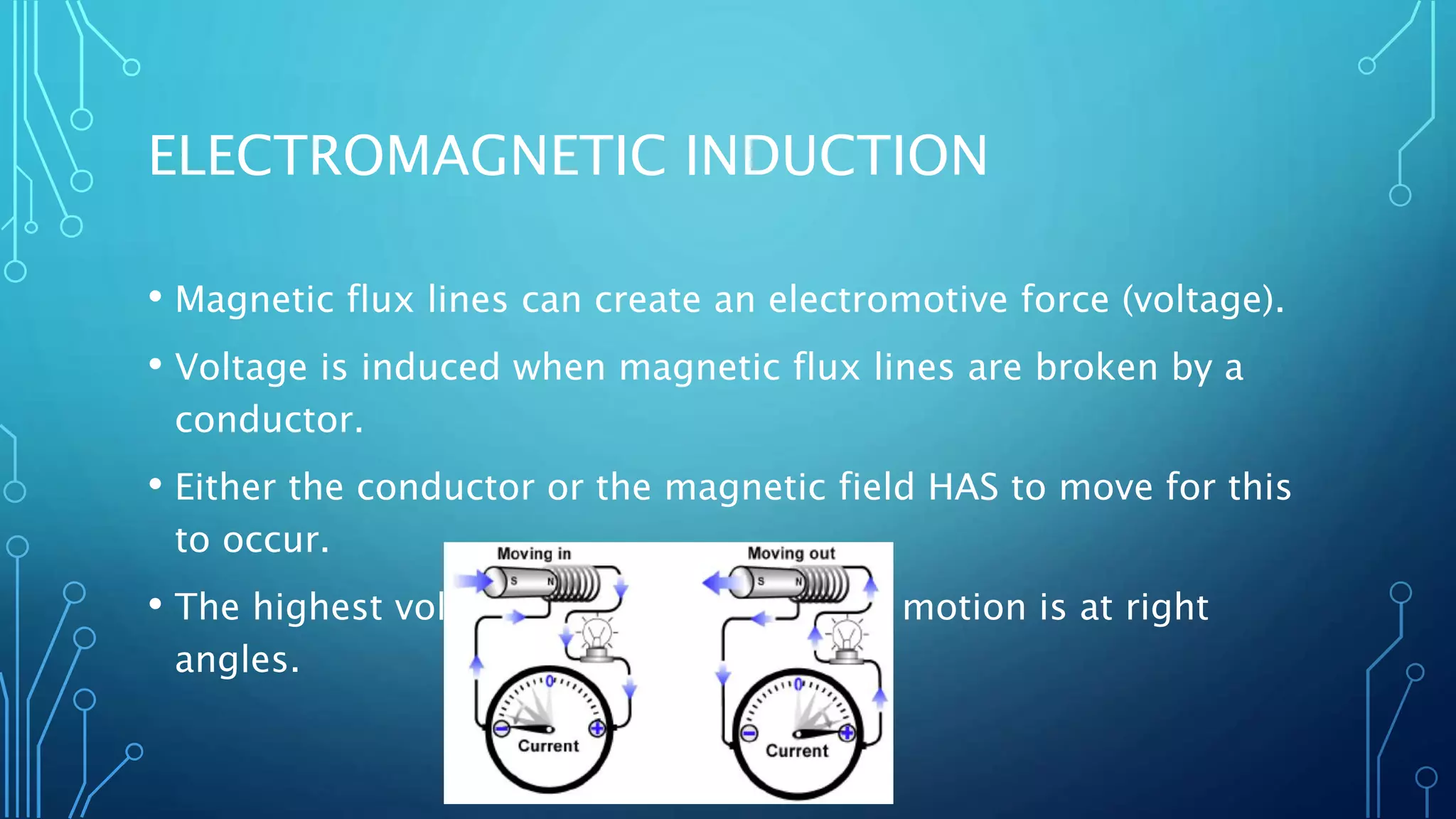

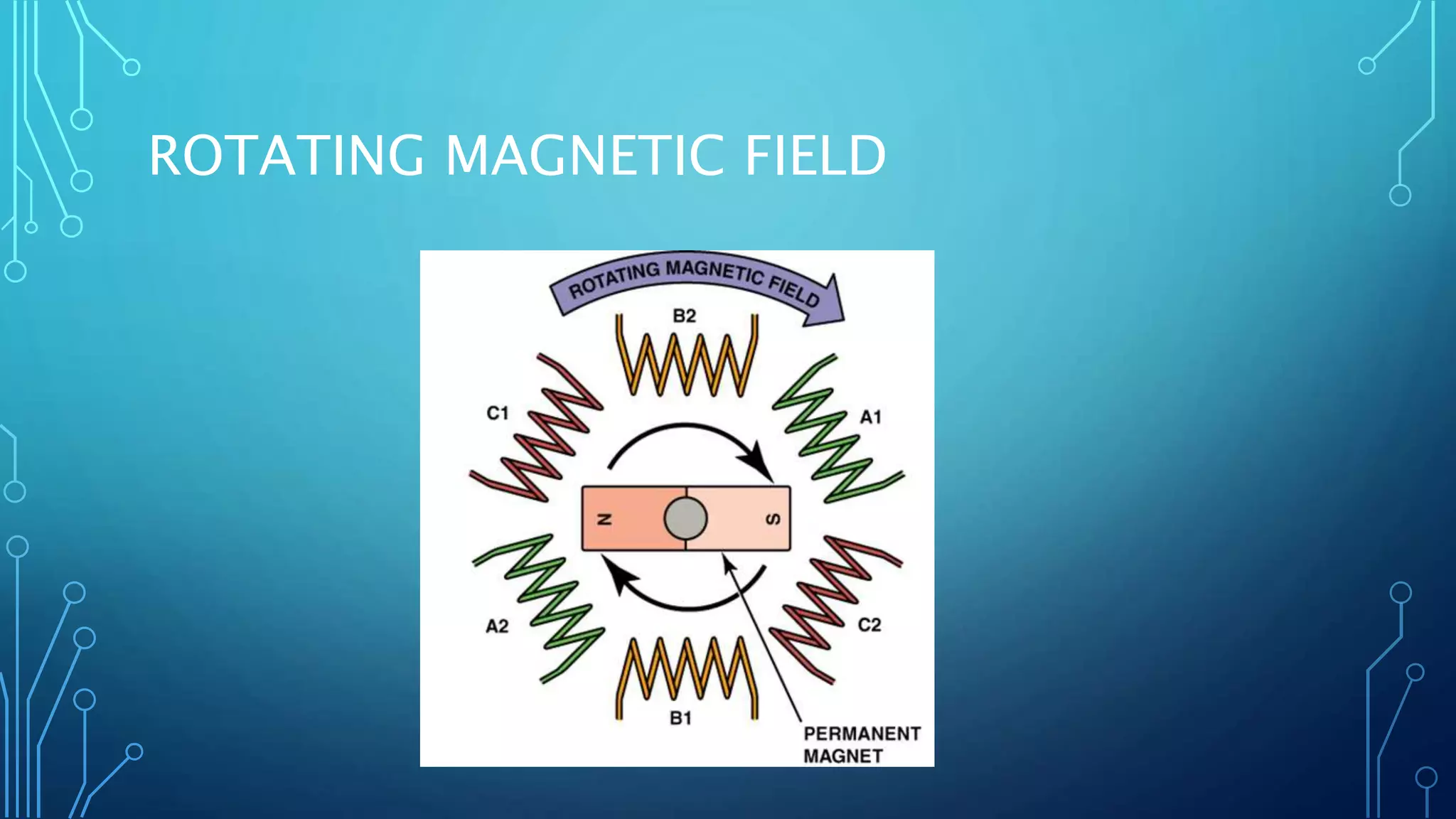

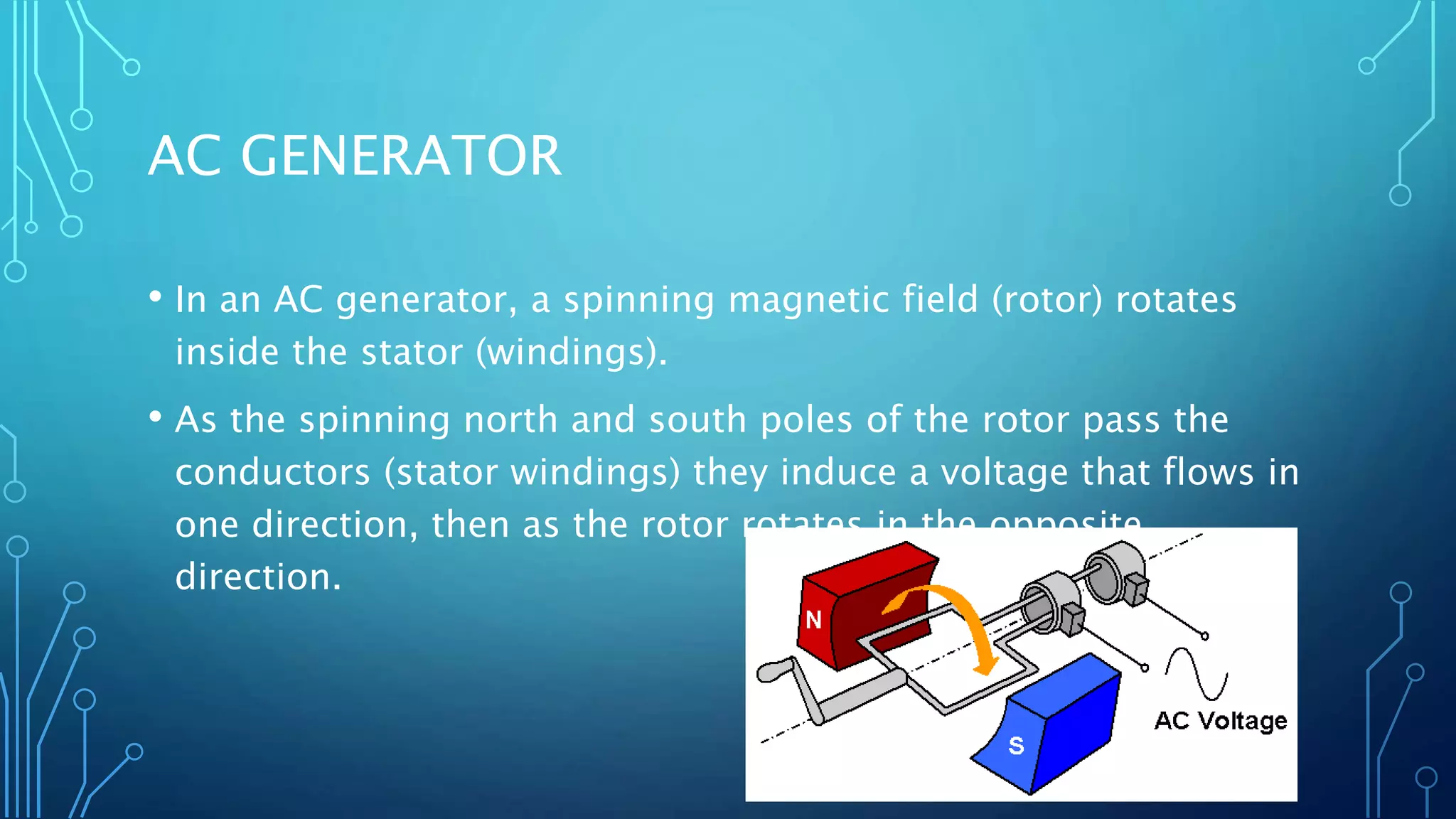

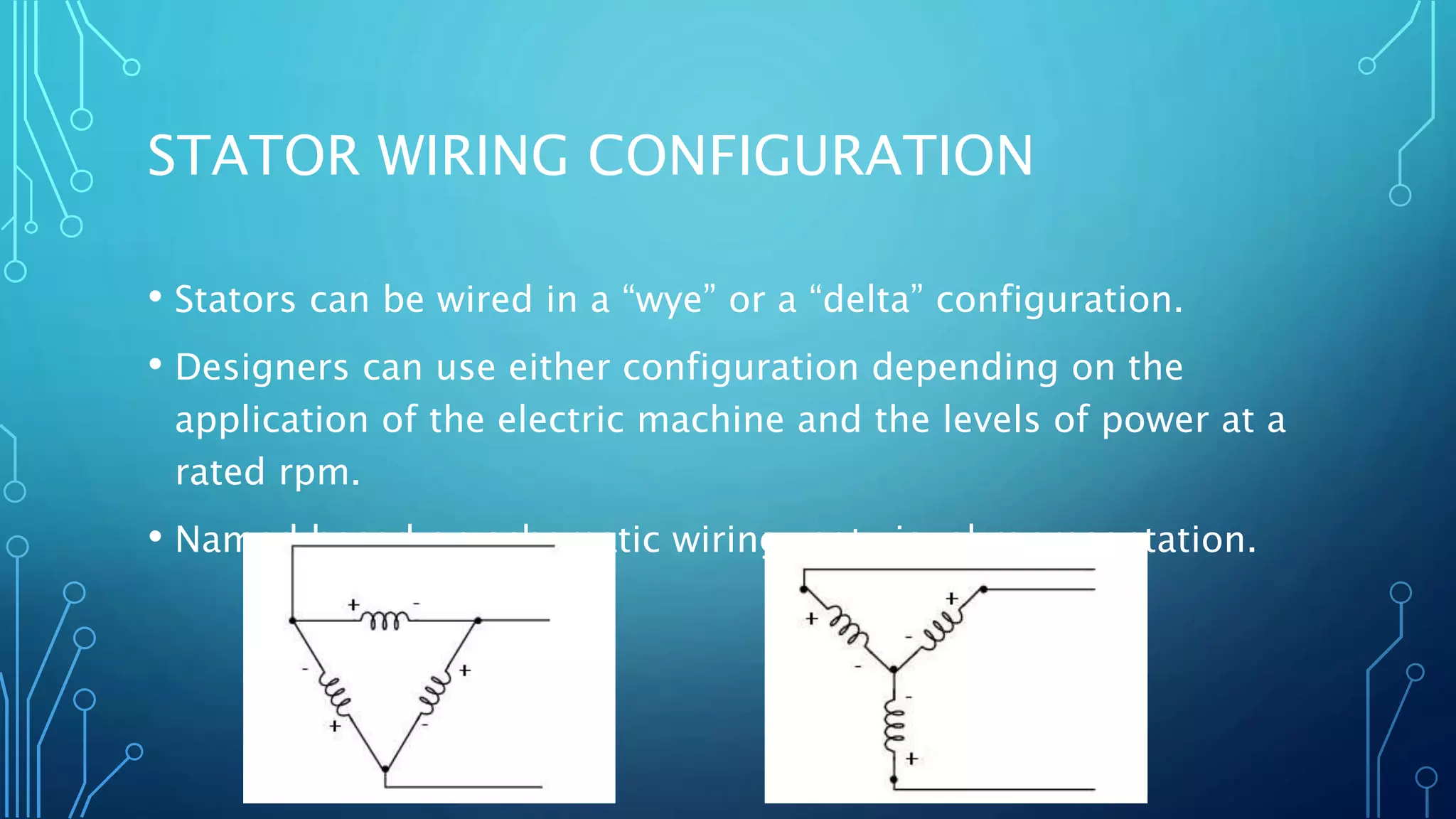

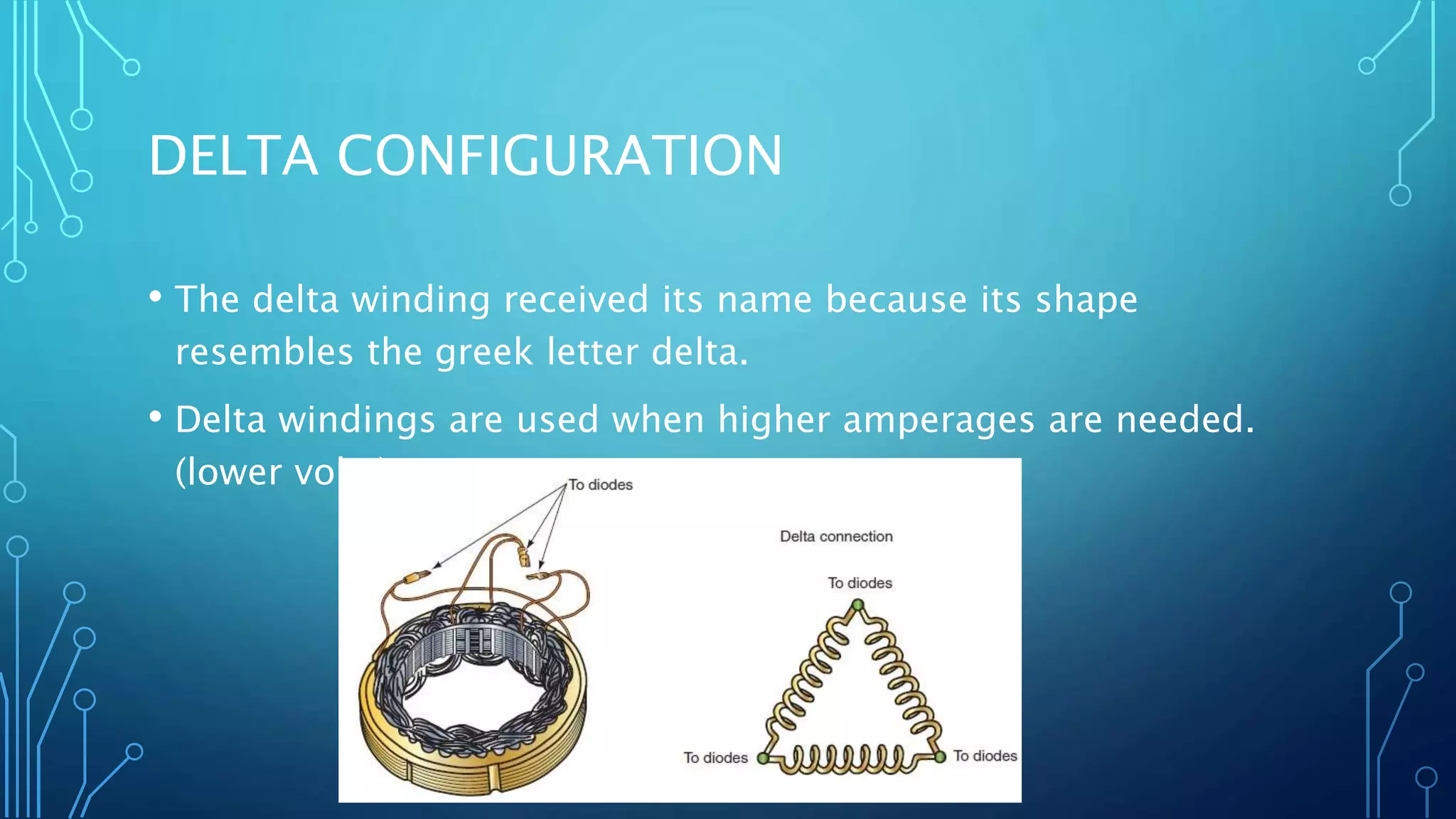

Magnetism and electromagnetism are related phenomena that can be used to generate electricity. Electric motors, generators and their controls rely on these principles. Motors use electromagnetic induction to convert electrical energy to mechanical motion, while generators operate in reverse to convert mechanical energy to electricity. Key components include magnetic fields, conductors, and switching devices that regulate current flow to produce rotation or induce voltage. Motors and generators are found in electric, hybrid and mild hybrid vehicle propulsion systems.