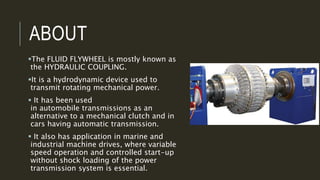

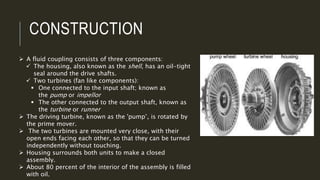

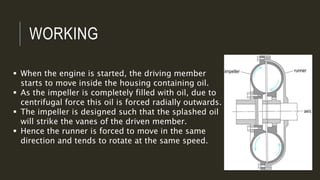

The fluid flywheel, also known as the hydraulic coupling, is a hydrodynamic device that transmits mechanical power, commonly used in automotive transmissions and industrial applications for smooth operation. It consists of a housing and two turbines that facilitate power transmission through kinetic fluid movement, typically utilizing low viscosity hydraulic fluids. Advantages include reduced wear from slipping, ease of operation compared to friction clutches, and absorption of sudden loads to minimize stress on transmission gears.