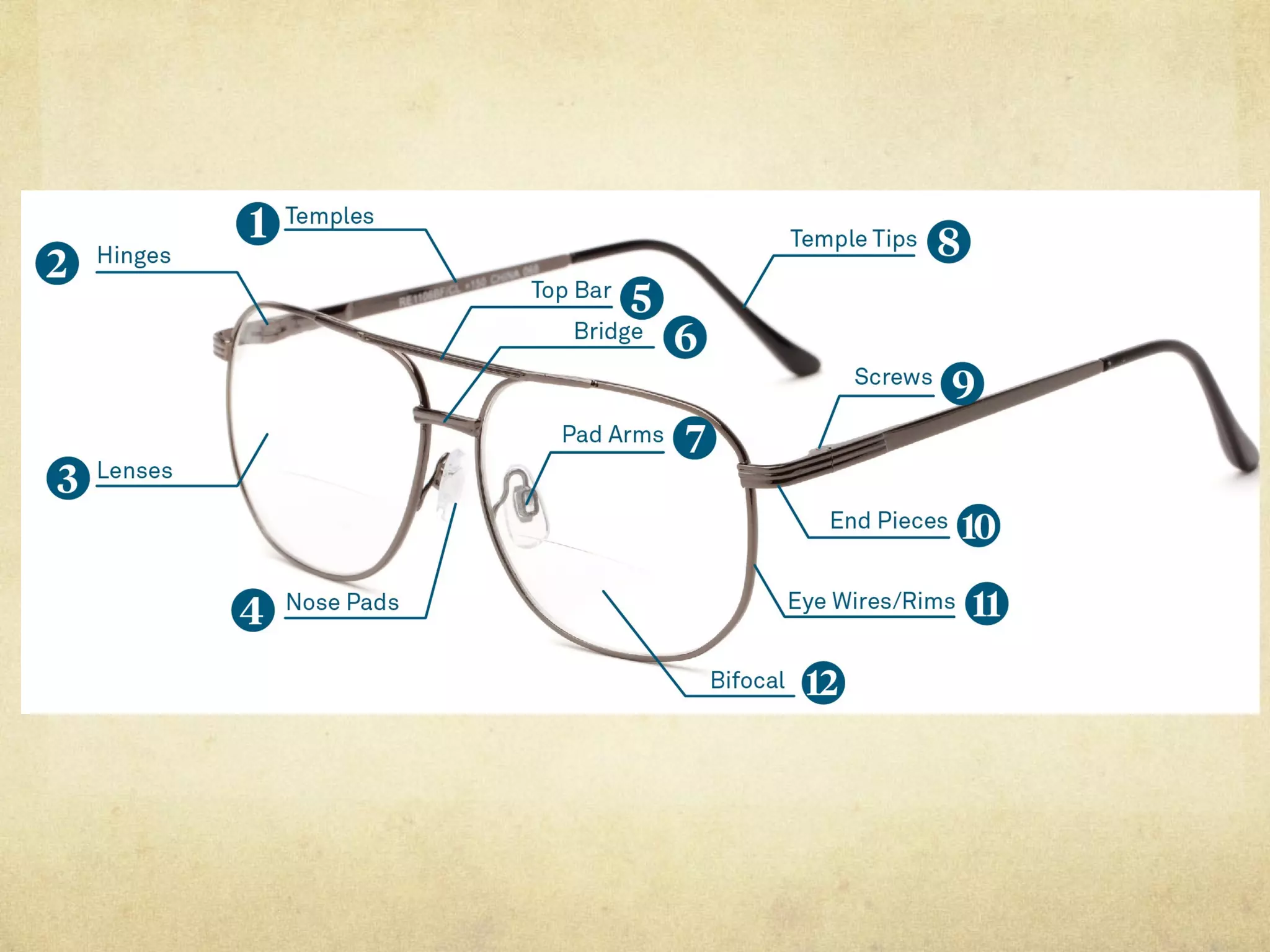

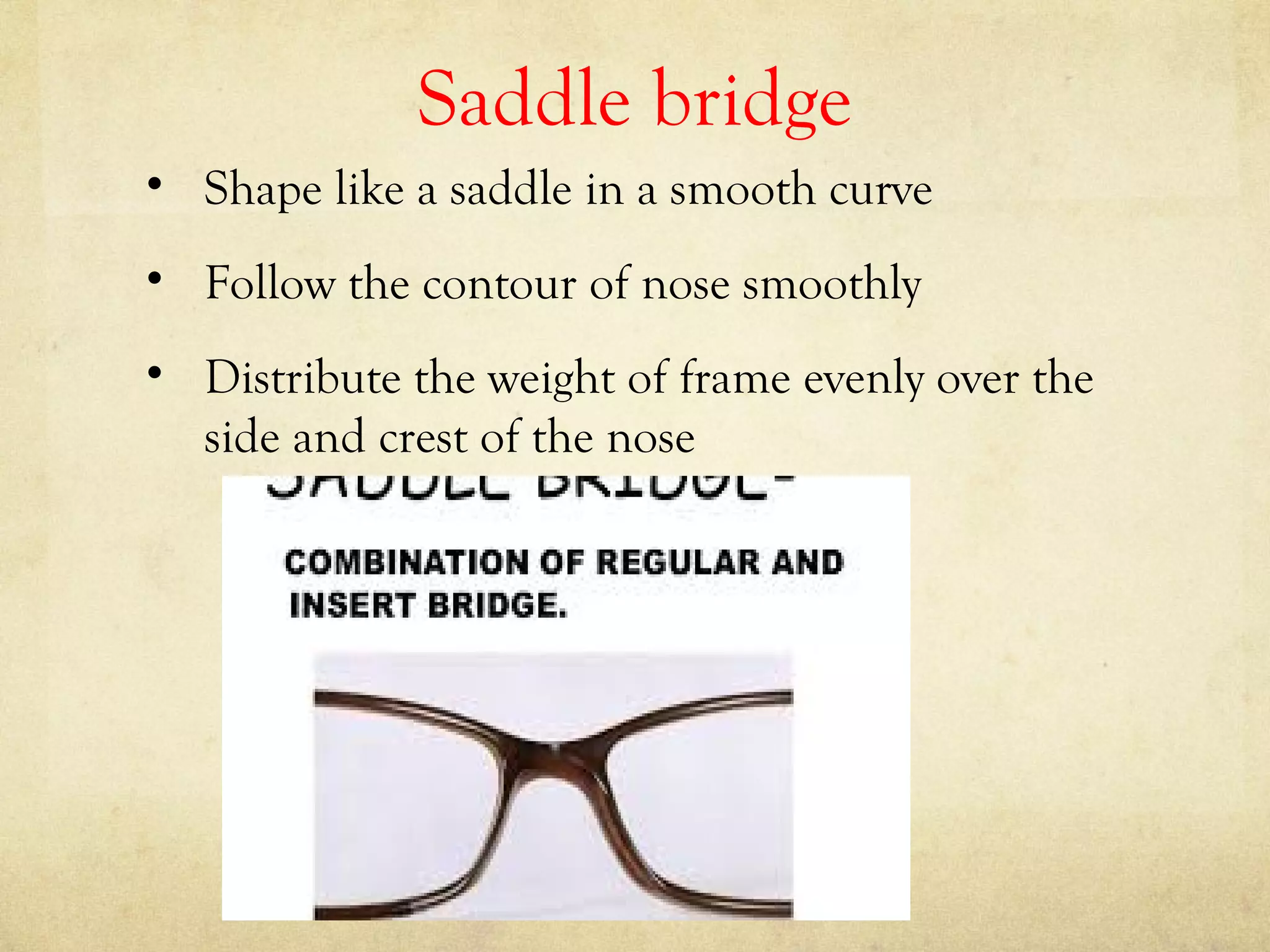

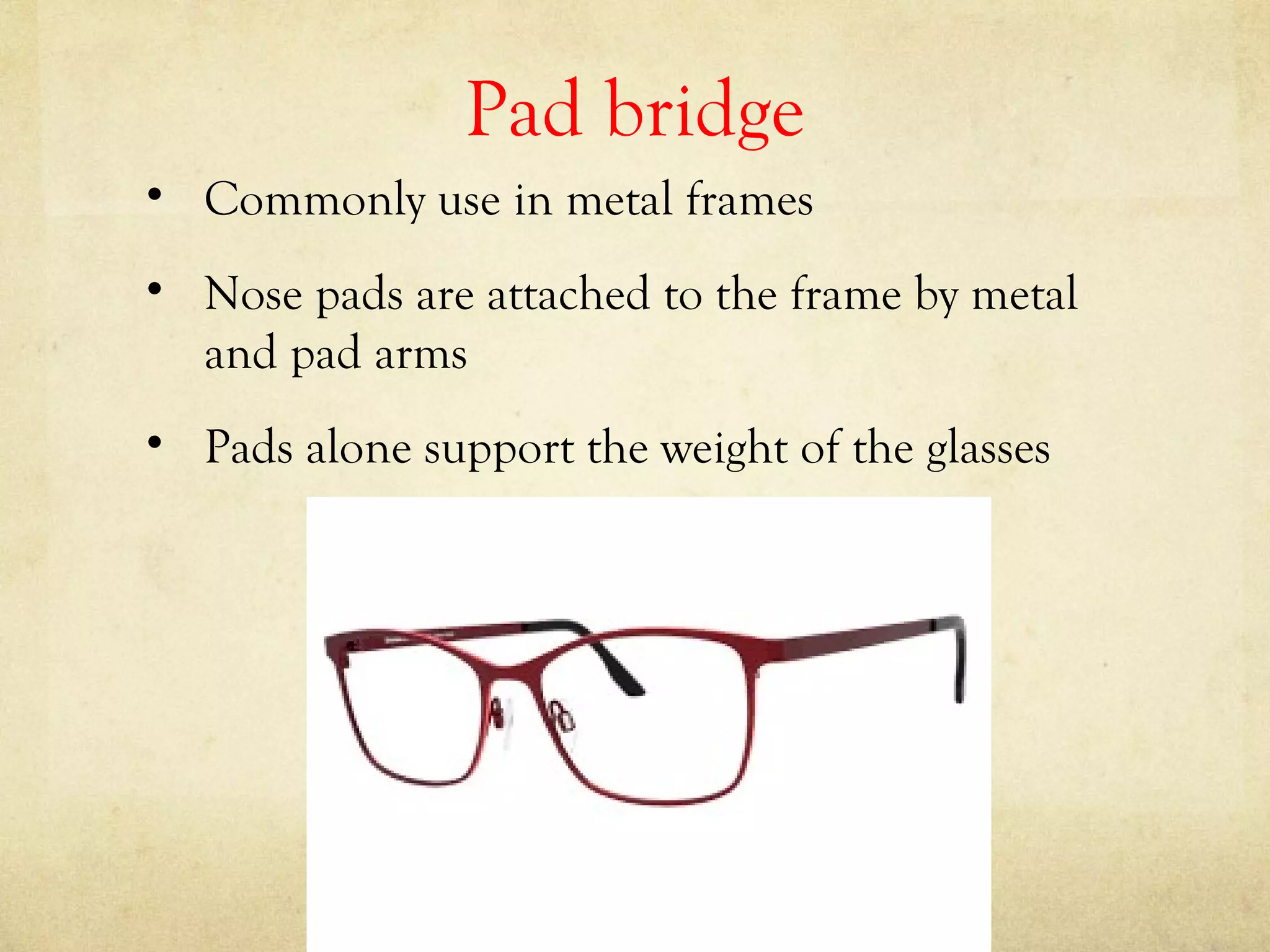

The document provides a comprehensive overview of eyewear frames, covering their parts, types, materials, and designs, along with considerations for fitting and lens attachment. It discusses the various frame materials, including metals and plastics, their properties, advantages, and disadvantages. Additionally, it explores specialized frame designs for different purposes, age groups, and professions, emphasizing the importance of comfort, style, and functionality in eyewear.