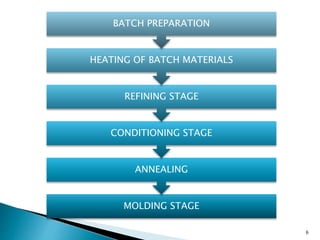

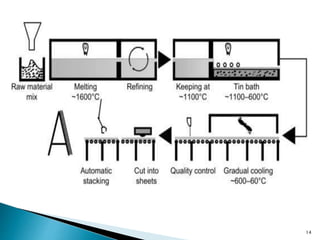

The document outlines the processes involved in glass production, detailing techniques such as batch and continuous-flow processes, along with specific materials needed for different glass types. Additionally, it covers the characteristics and applications of thermoplastic and thermosetting materials used in polymerization and molding. Key stages of glass fabrication include batch preparation, refining, conditioning, and annealing, emphasizing the transformation of raw materials into finished products.