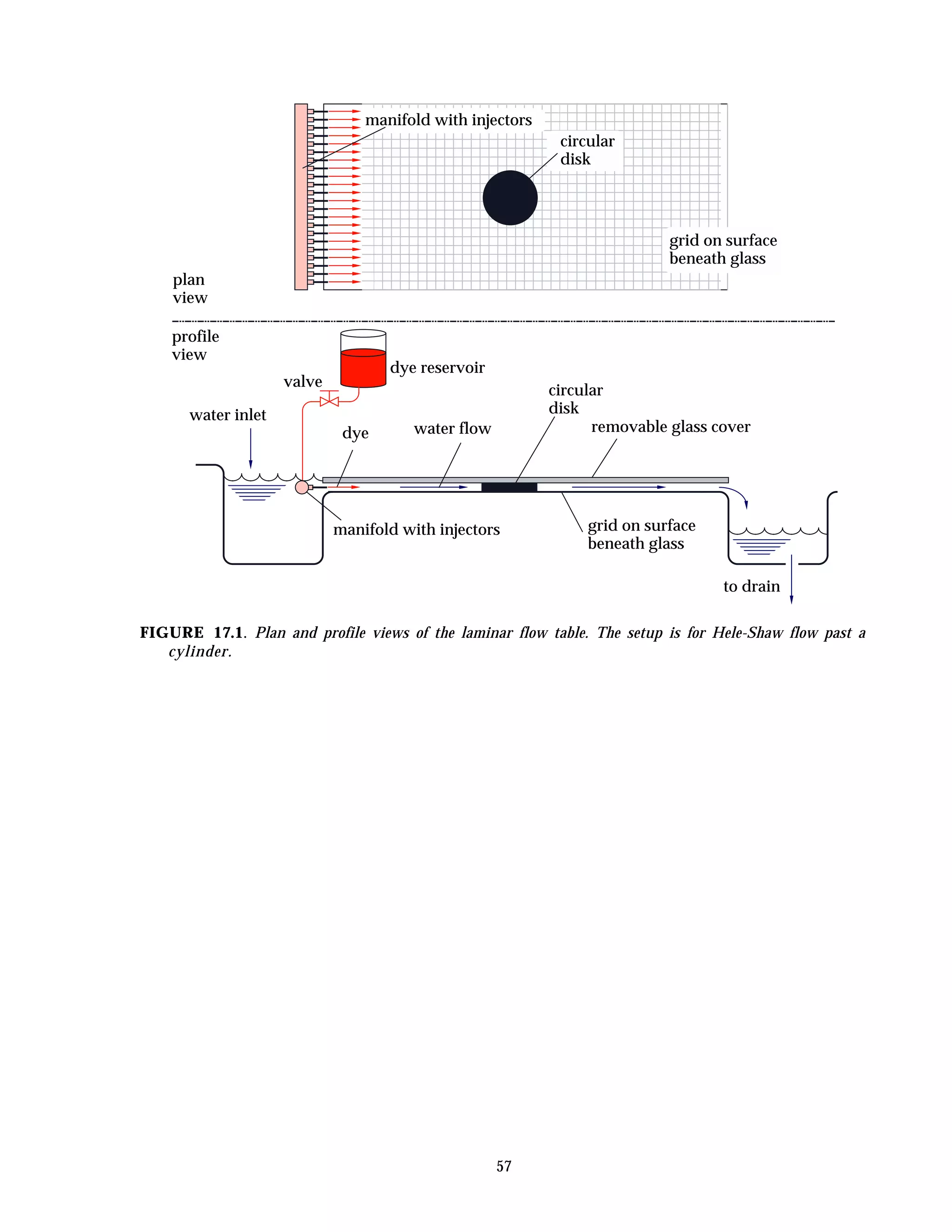

This document provides instructions and guidelines for conducting experiments in a fluid mechanics laboratory. It begins with an overview of course learning outcomes, safety procedures, and expectations for cleaning the lab space. It then discusses proper experimental methodology, including defining hypotheses, designing experiments to test hypotheses, collecting accurate and precise measurements, and analyzing results. The document emphasizes minimizing errors and uncertainties in measurements. It provides definitions for key terms like error, uncertainty, accuracy, and precision when evaluating experimental data. Finally, it outlines the content and procedures for 20 specific fluid mechanics experiments that will be conducted.

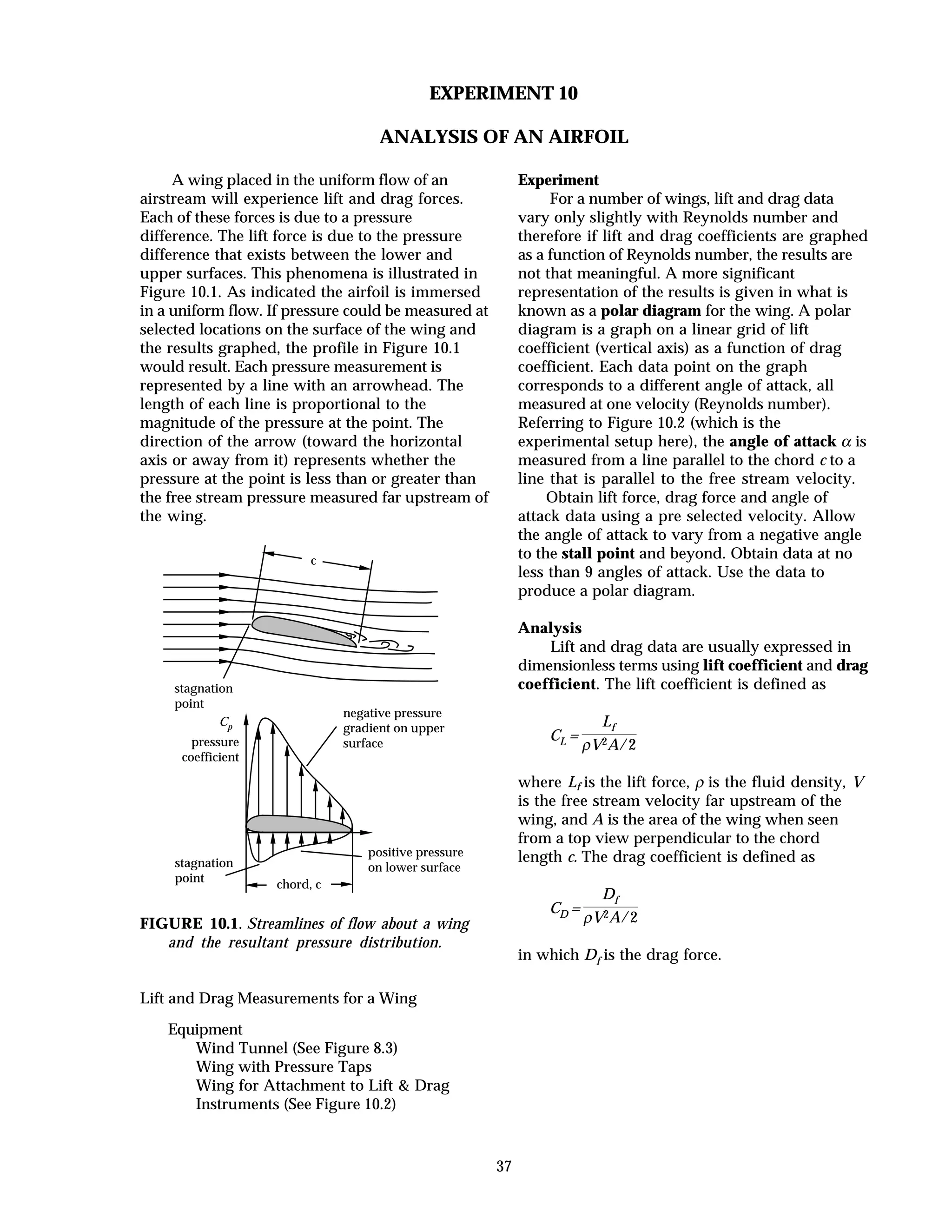

![48

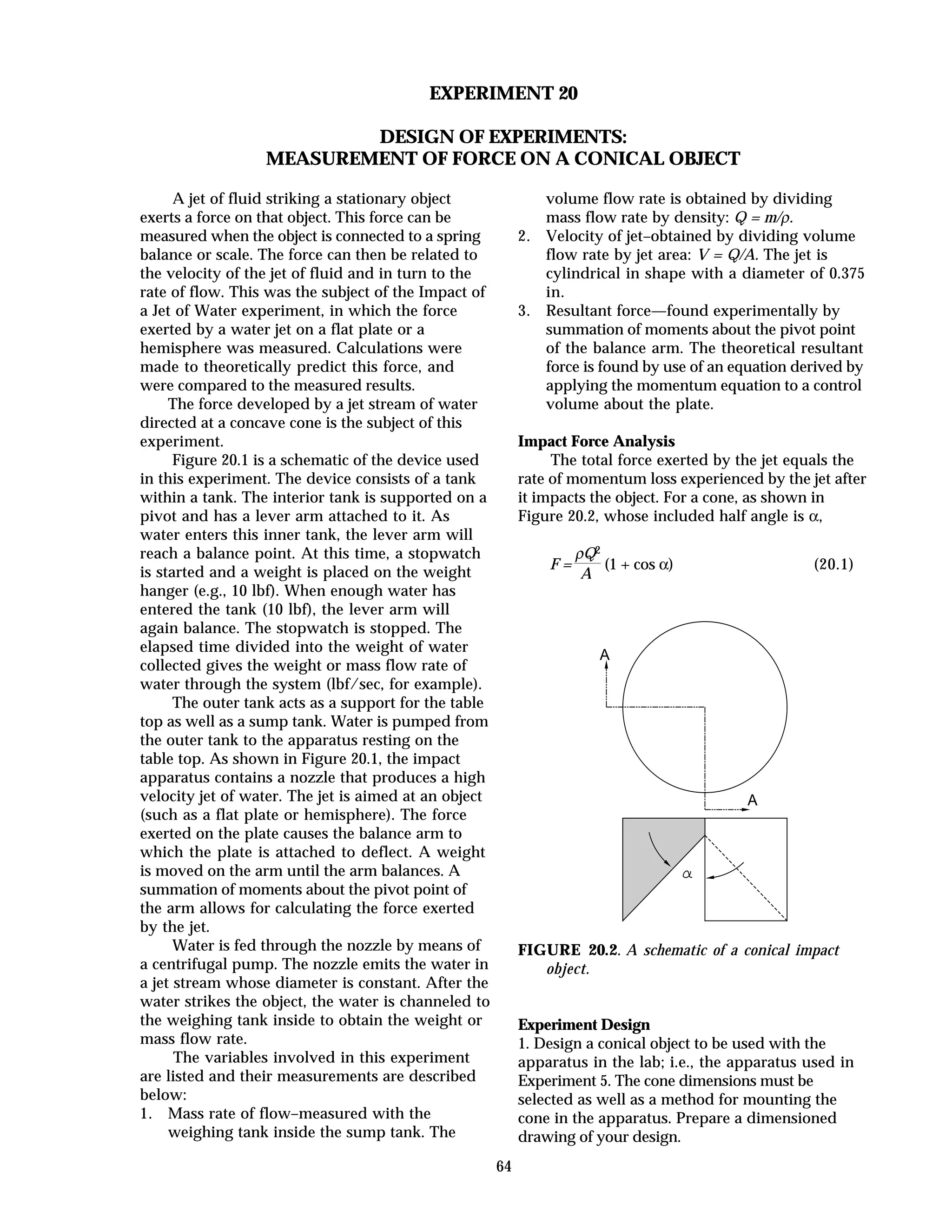

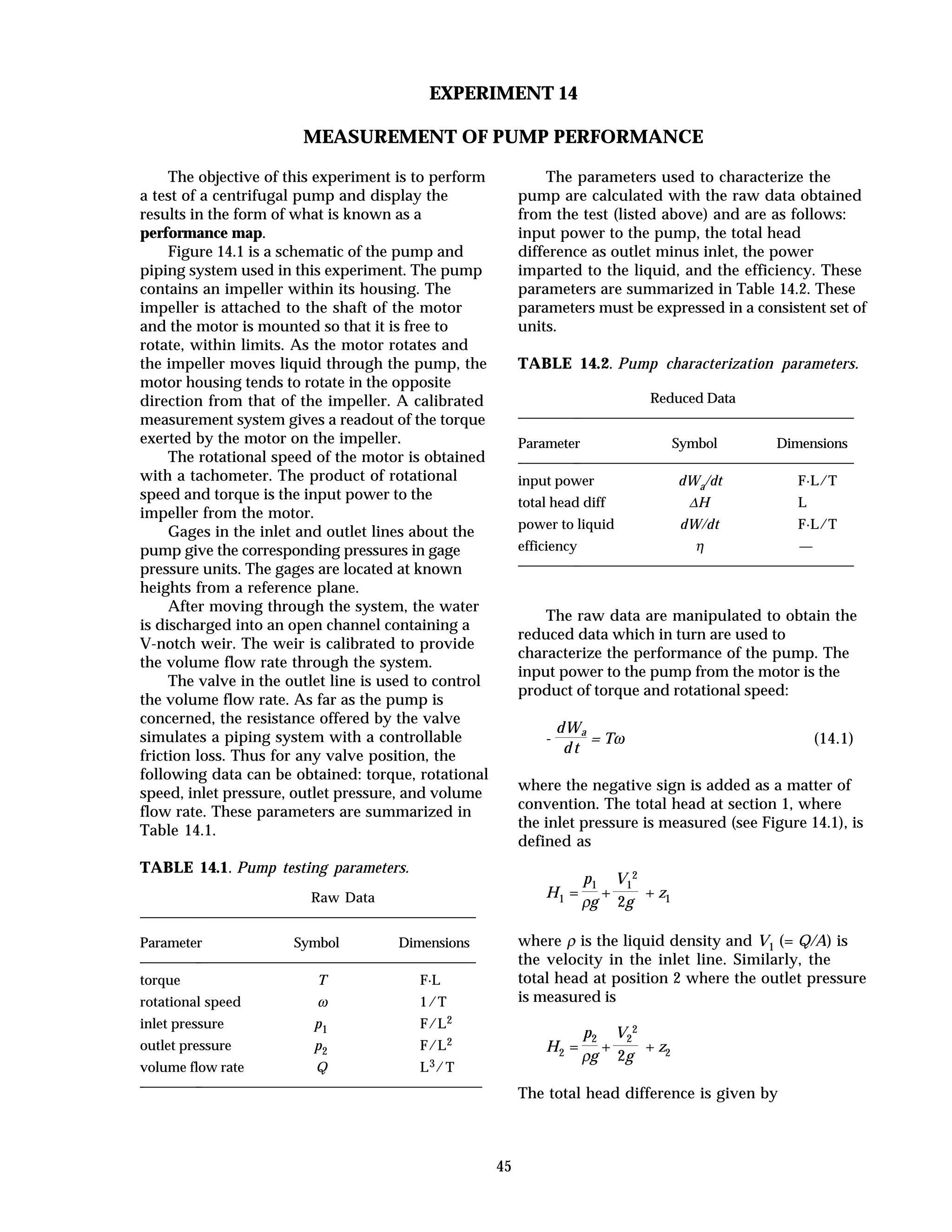

Specific Speed

A dimensionless group known as specific

speed can also be derived. Specific speed is found

by combining head coefficient and flow

coefficient in order to eliminate characteristic

length D:

ωss =

Q

ωD3

1/2

ω2D2

g∆H

3/4

or ωss =

ωQ1/2

(g∆H)3/4 [dimensionless]

Exponents other than 1/2 and 3/4 could be used (to

eliminate D), but 1/2 and 3/4 are customarily

selected for modeling pumps. Another definition

for specific speed is given by

ωs =

ωQ1/2

∆H3/4

rpm =

rpm(gpm)1/2

ft3/4

in which the rotational speed ω is expressed in

rpm, volume flow rate Q is in gpm, total head ∆H

is in ft of liquid, and specific speed ωs is

arbitrarily assigned the unit of rpm. The equation

for specific speed ωss is dimensionless whereas

ωs is not.

The specific speed of a pump can be

calculated at any operating point, but

customarily specific speed for a pump is

determined only at its maximum efficiency. For

the pump of this experiment, calculate its

specific speed using both equations.](https://image.slidesharecdn.com/fluidslabmanual2-140524214604-phpapp01/75/Fluids-lab-manual_2-48-2048.jpg)

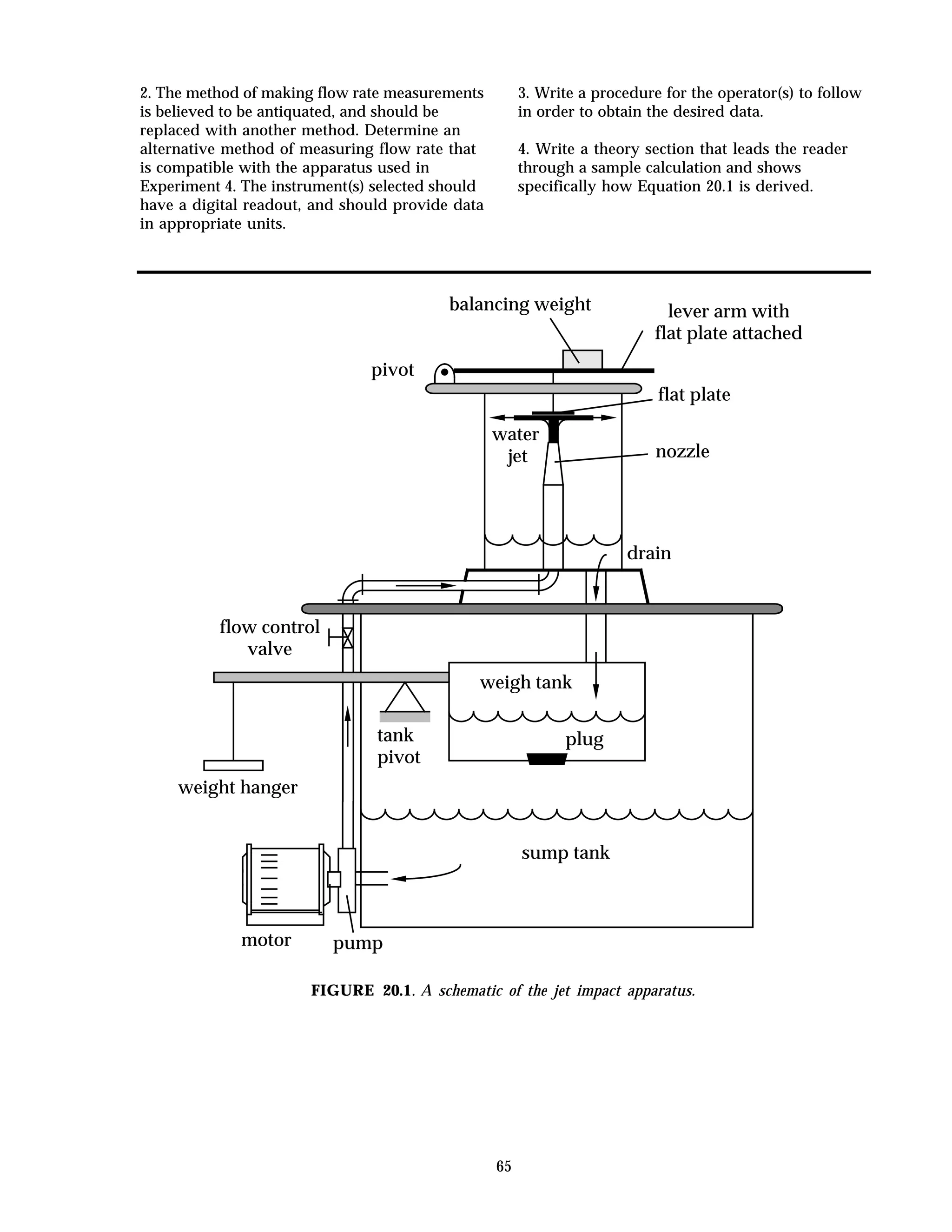

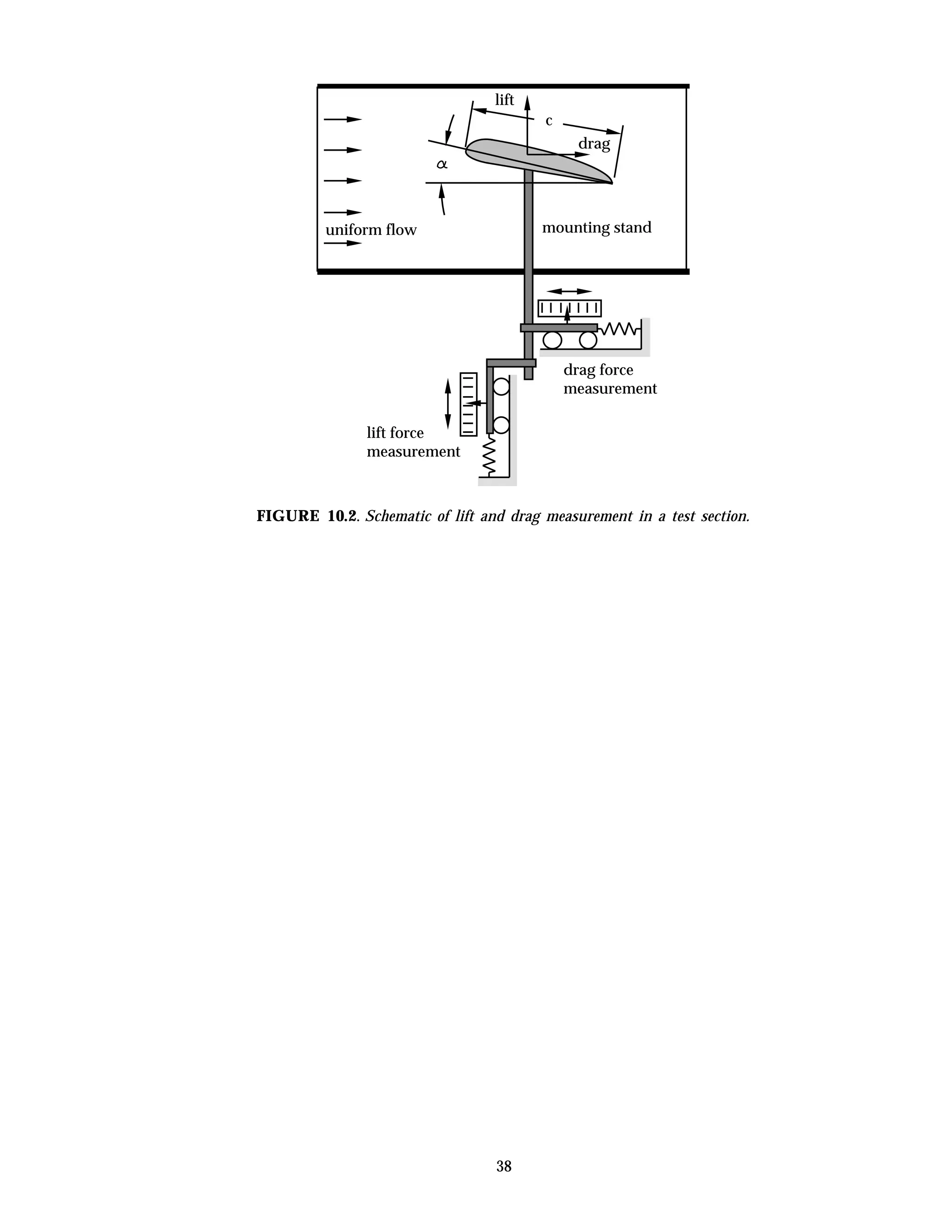

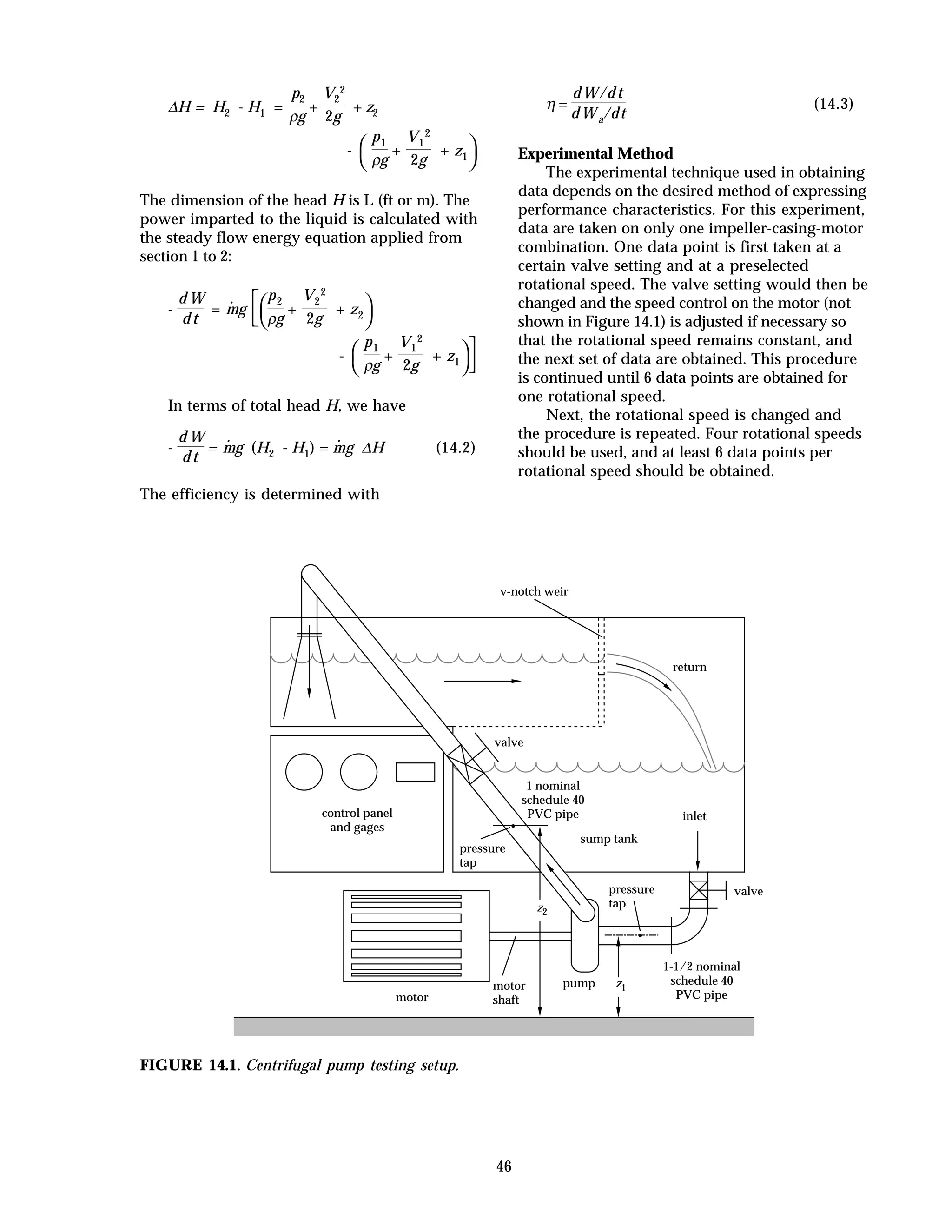

![53

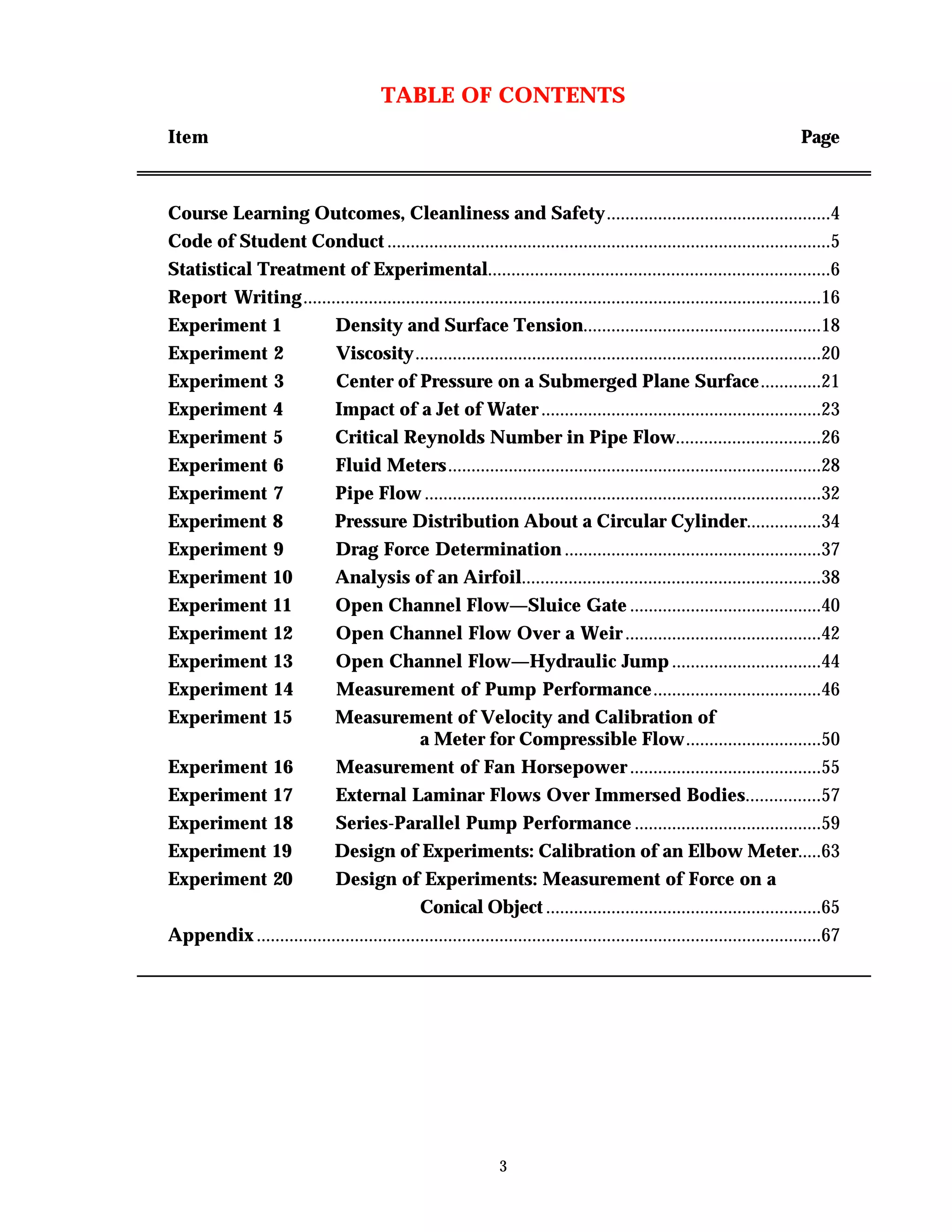

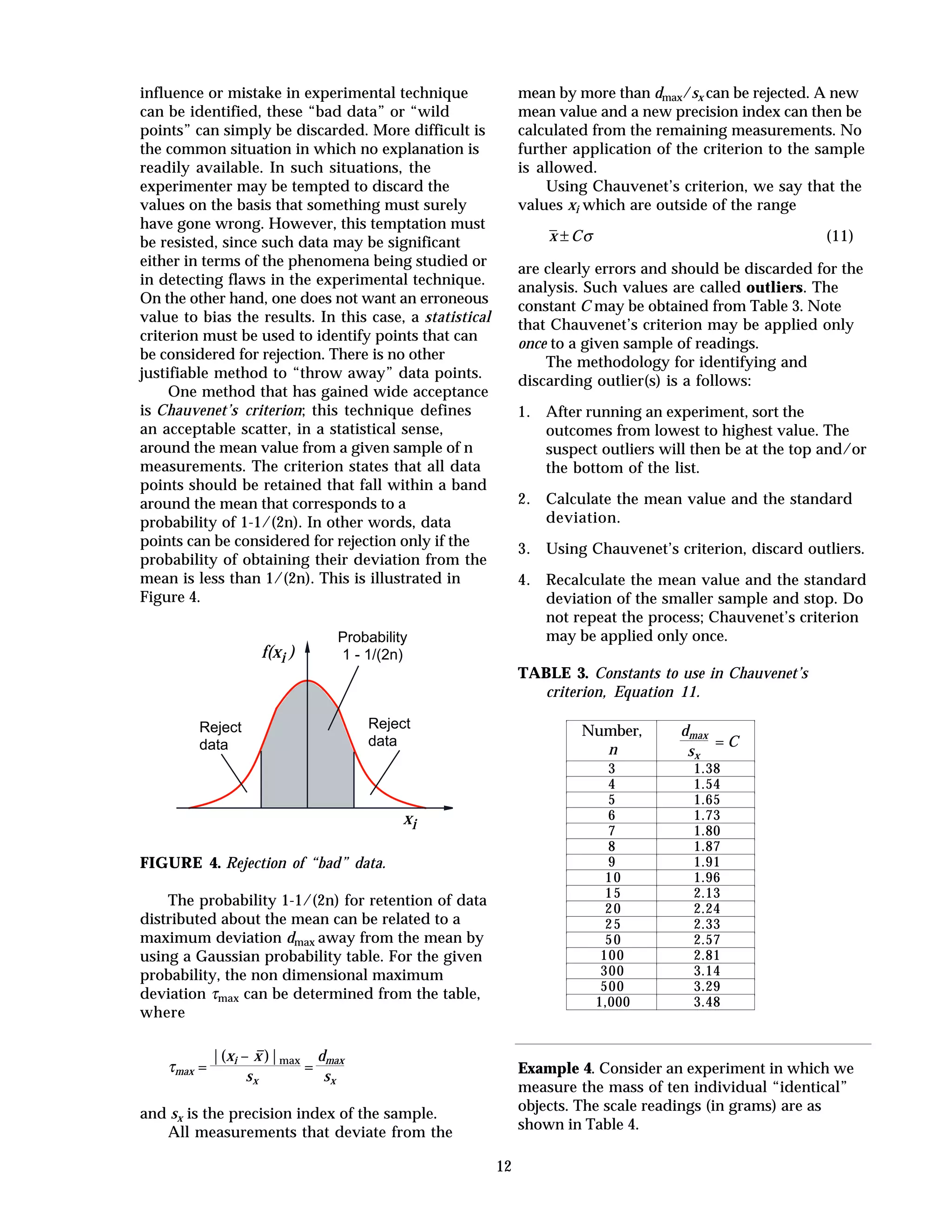

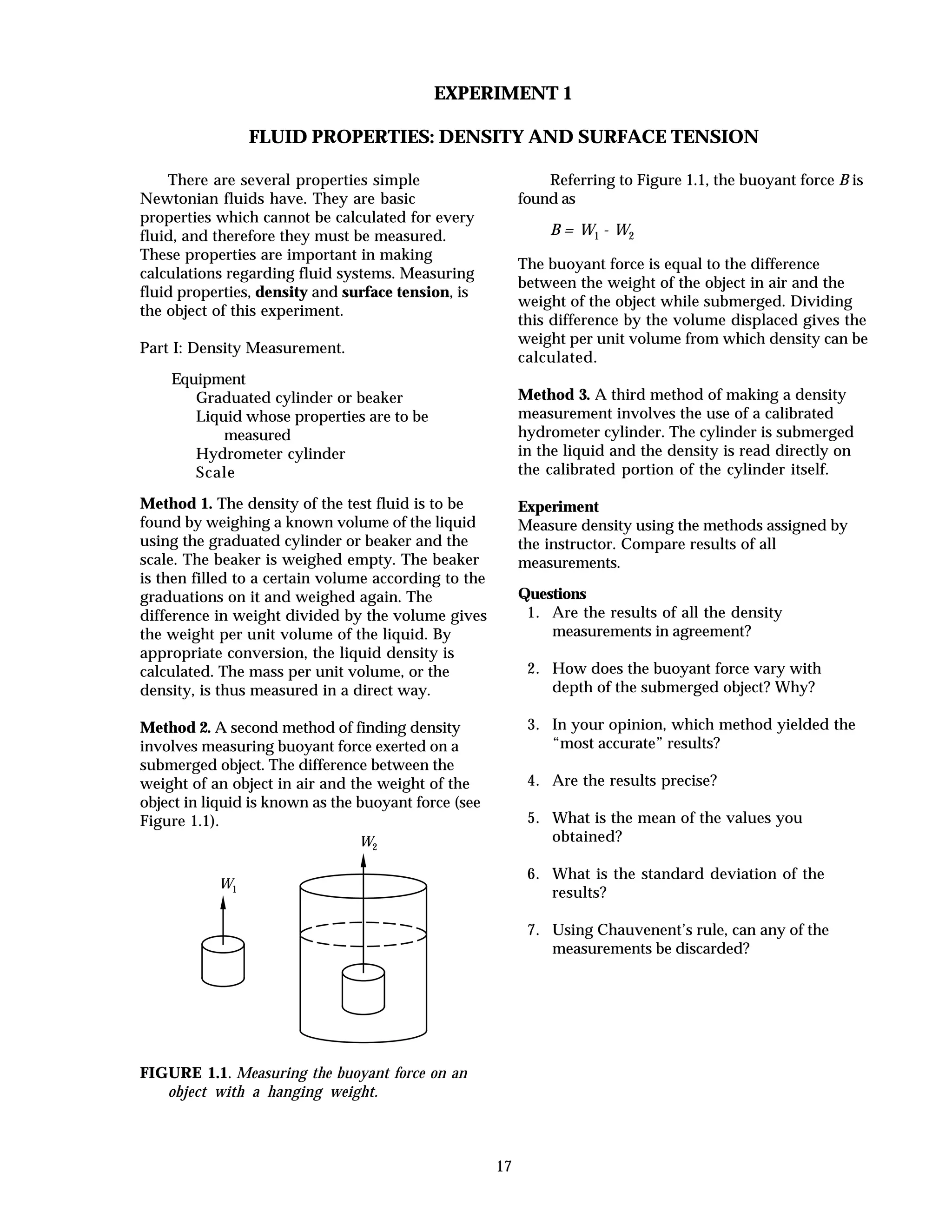

TABLE 15.1. Summary of equations for compressible flow through a venturi or an orifice meter.

·

ms = A2

2p1ρ1 (p2/p1)2/γ [γ/(γ - 1)] [1 - (p2/p1)(γ - 1)/γ

]

1 - (p2/p1)2/γ (D2

4/D1

4)

1/2

(15.1)

·

mac = Cv A2

2p1ρ1 (p2/p1)2/γ [γ/(γ - 1)] [1 - (p2/p1)(γ - 1)/γ

]

1 - (p2/p1)2/γ (D2

4/D1

4)

1/2

(15.2)

Y =

√γ

γ - 1

[(p2/p1)2/γ - (p2/p1)(γ + 1)/γ](1 - D2

4/D1

4)

[1 - (D2

4/D1

4)(p2/p1)2/γ](1 - p2/p1)

(venturi meter) (15.3)

Y = 1 - (0.41 + 0.35β 4)

(1 - p2/p1)

γ

(orifice meter) (15.4)

rounded

inlet

outlet ductaxial flow

fan

motor

manometer

connections

pitot-static

tube

venturi meter

FIGURE 15.4. Experimental setup for calibrating a venturi meter.

rounded

inlet

outlet ductaxial flow

fan

motor

orifice plate

manometer

connections

pitot-static

tube

FIGURE 15.5. Experimental setup for calibrating an orifice meter.](https://image.slidesharecdn.com/fluidslabmanual2-140524214604-phpapp01/75/Fluids-lab-manual_2-53-2048.jpg)

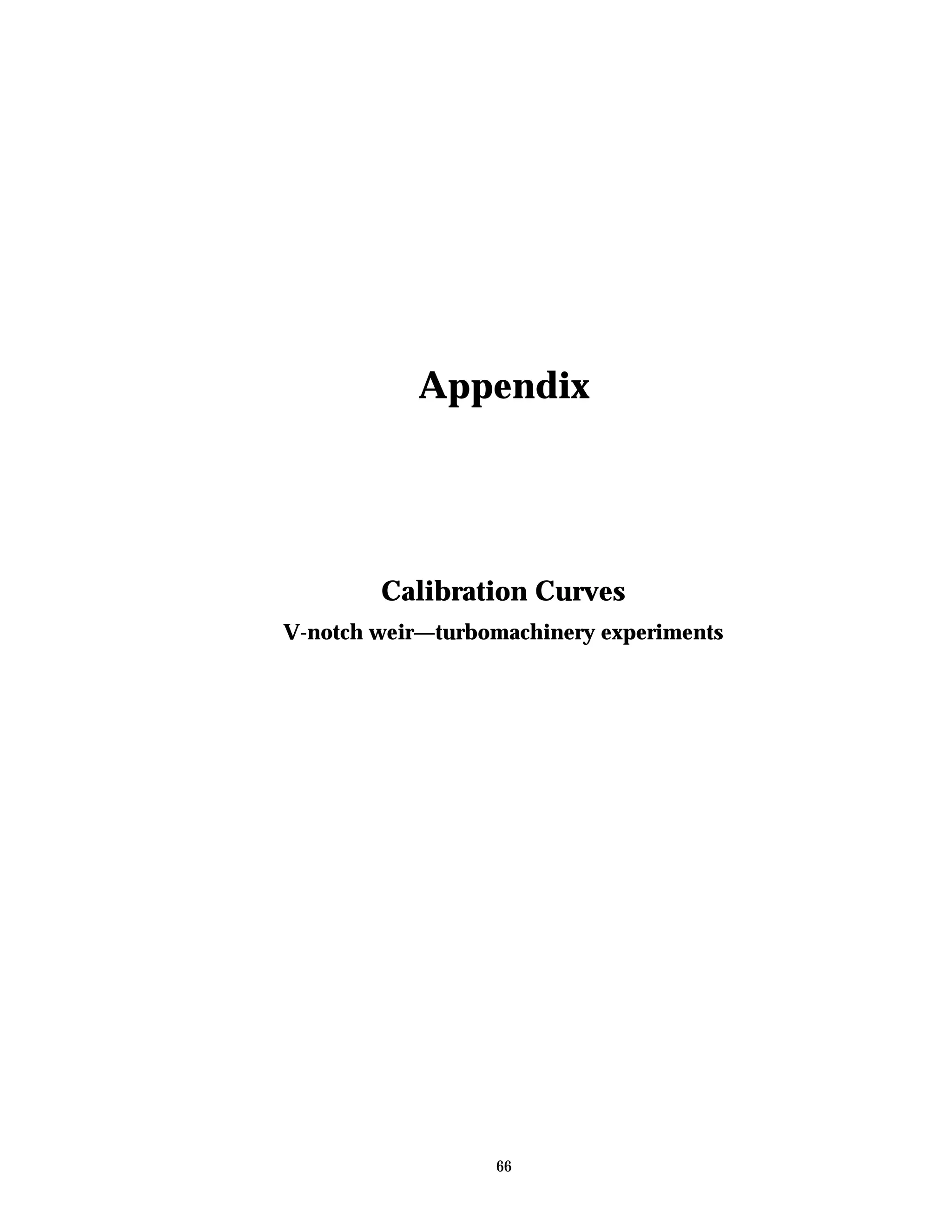

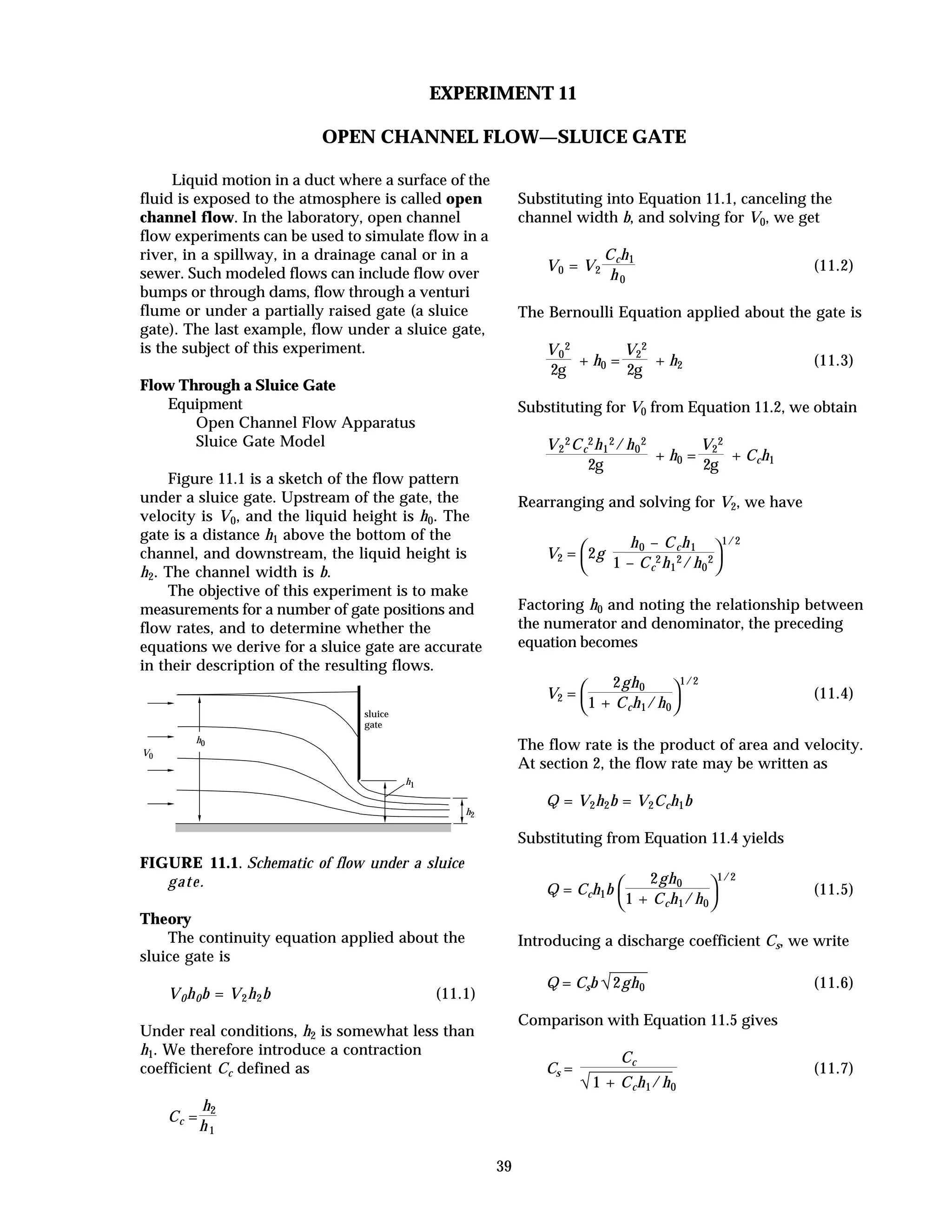

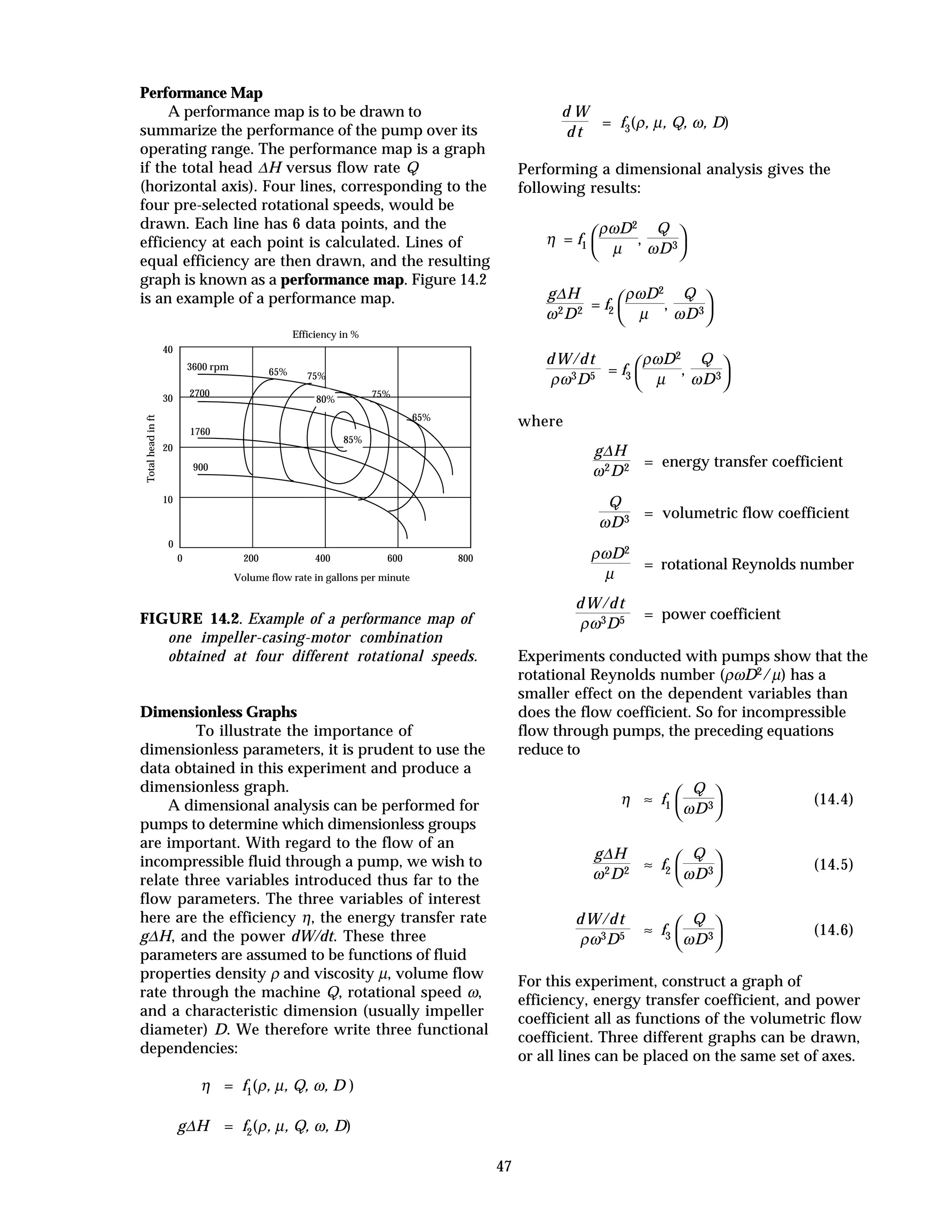

![59

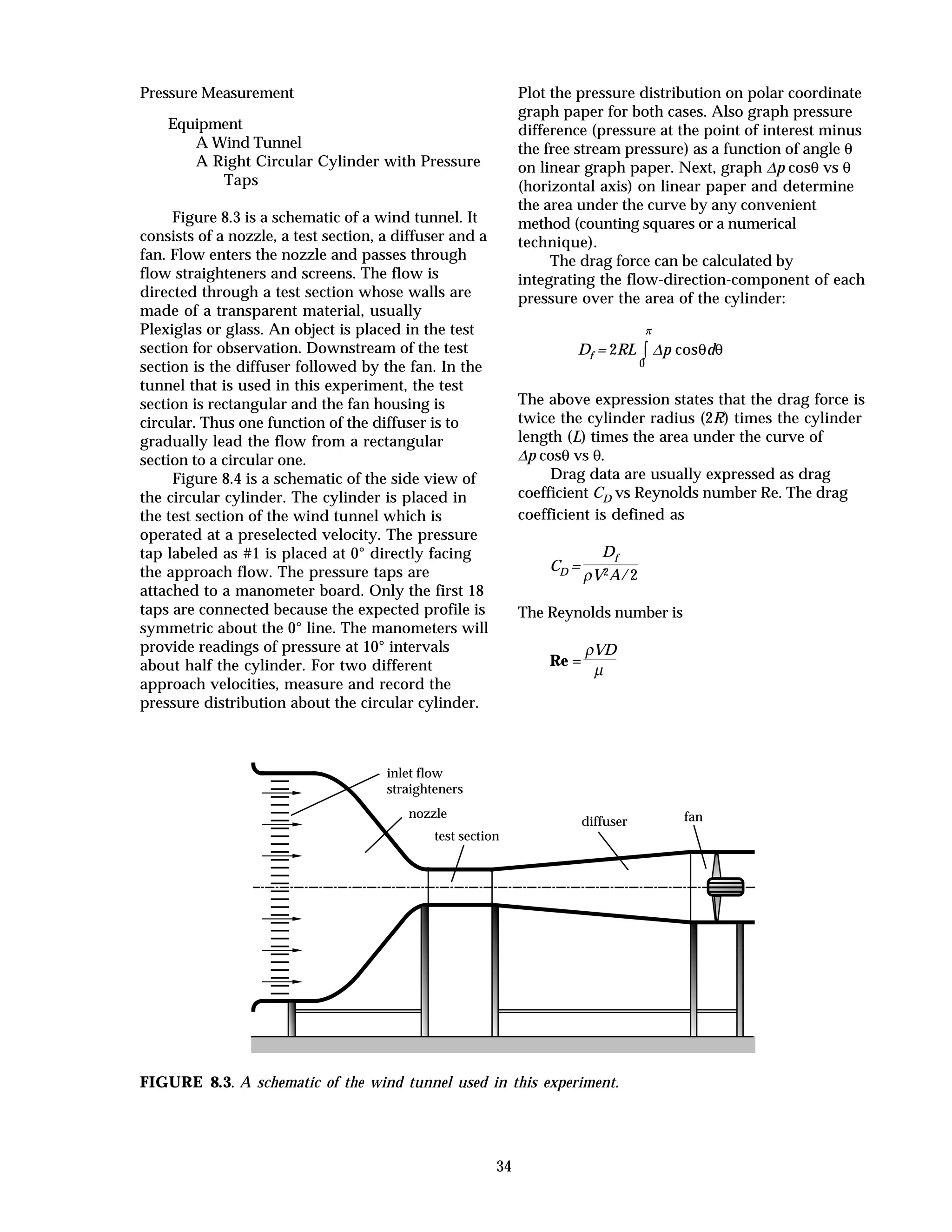

Single Pump Performance

The objective here is to obtain a head flow

curve (∆H vs Q) for a centrifugal pump

operating at one speed.

Procedure

• Launch the program FM21SNGL on the

computer.

• Use pump (1) and be sure that the valves

are set appropriately: valves A, B, and E

are open. Valves C and D are closed.

• Start pump (1); pump (2) should remain off.

Decide on a power setting for pump (1) [such

as 50% or 75% or 100%] and set its controller

accordingly. This setting is used for this

and the subsequent experiments.

• Select “Diagrm” and note the value of the

volume flow rate displayed by the

computer.

• Decide on suitable increments to use for flow

rate so that typically 15 data points are

obtained between zero and maximum flow

rate.

• Close valve E for the condition of no flow

(Q = 0). When the readings on the screen

become sufficiently steady, select “Take

Sample.” This is the first data point. DO

NOT allow the pump to operate at zero

flow for any longer than necessary.

• Open valve E slightly to the first increment

in flow rate decided upon earlier. When

the readings are sufficiently steady, select

“Take Sample.”

• Repeat the previous step for other settings

of valve E, corresponding to increasing

values of flow rate. The last sample point

corresponds to valve E being fully open.

• The recorded data set can now be examined

via any of the selectable options:

“Graphs,” “Tables,” or downloaded into a

spreadsheet. Select the “Graphs” option

and obtain a head versus flow rate curve.

(See software help screens if necessary.)

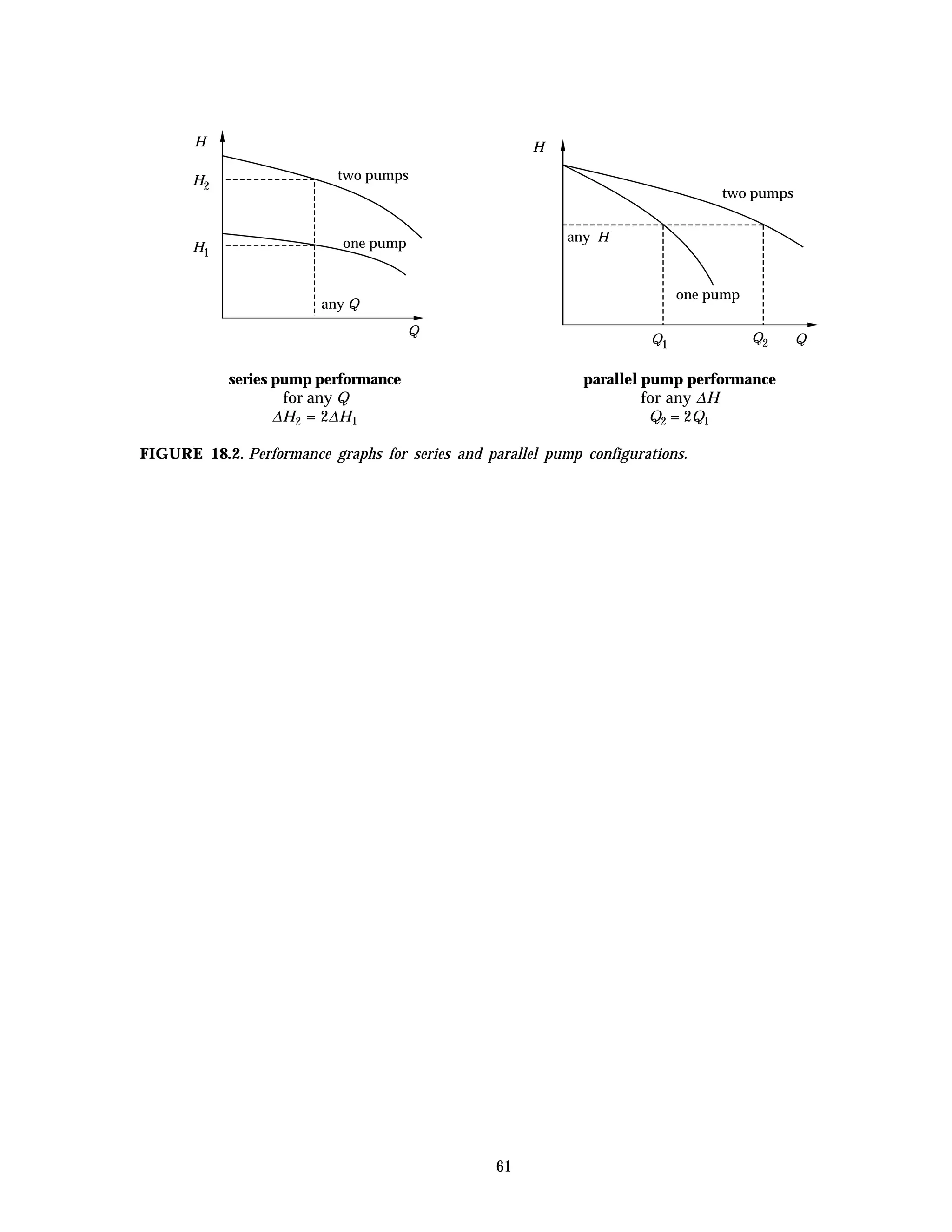

Series Pump Performance

The objective here is to obtain a head flow

curve (∆H vs Q) for a two identical centrifugal

pumps operating at the same speed, and

operated such the flow leaving pump (1) enters

that of pump (2). When two pumps operate in

series, the combined head versus flow rate

curves is found by adding the heads of the

single pump curves at the same flow rates.

Procedure

• Launch the program FM21SERS on the

computer.

• Use both pumps and be sure that the valves

are set appropriately: valve A is closed.

All other valves are open.

• Start both pumps, and set them on the same

power setting that was used in the single

pump experiment. This setting is used for

this and the subsequent experiment.

• Select “Diagrm” and note the value of the

volume flow rate displayed by the

computer.

• Decide on suitable increments to use for flow

rate so that typically 15 data points are

obtained between zero and maximum flow

rate.

• Close valve E for the condition of no flow

(Q = 0). When the readings on the screen

become sufficiently steady, select “Take

Sample.” This is the first data point. DO

NOT allow the pump to operate at zero

flow for any longer than necessary.

• Open valve E slightly to the first increment

in flow rate decided upon earlier. When

the readings are sufficiently steady, select

“Take Sample.”

• Repeat the previous step for other settings

of valve E, corresponding to increasing

values of flow rate. The last sample point

corresponds to valve E being fully open.

• The recorded data set can now be examined

via any of the selectable options:

“Graphs,” “Tables,” or downloaded into a

spreadsheet. Select the “Graphs” option

and obtain a head versus flow rate curve.

(See software help screens if necessary.)

Parallel Pump Performance

The objective here is to obtain a head flow

curve (∆H vs Q) for a two identical centrifugal

pumps operating at the same speed, and

operated in parallel. Both pumps take in water

from the tank, and discharge the water into a

common line containing the valve at E. When

two pumps operate in parallel, the combined

head versus flow rate curves is found by adding

the flow rates of the single pump curves at the

same head.

Procedure

• Launch the program FM21PARA on the

computer.

• Use both pumps and be sure that the valves

are set appropriately: valve D is closed.

All other valves are open. .

• Start both pumps, and set them on the same

power setting that was used in the single

pump experiment.](https://image.slidesharecdn.com/fluidslabmanual2-140524214604-phpapp01/75/Fluids-lab-manual_2-59-2048.jpg)

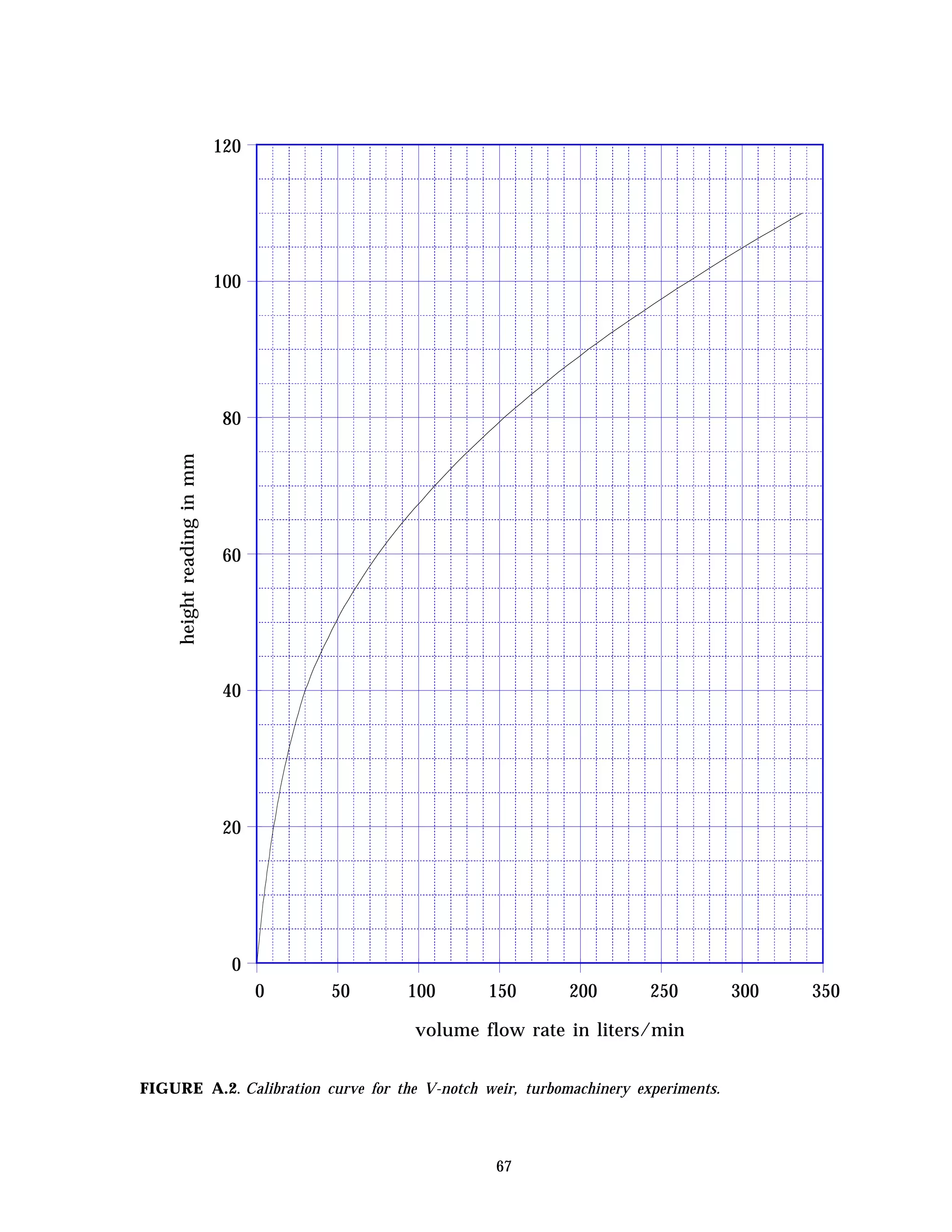

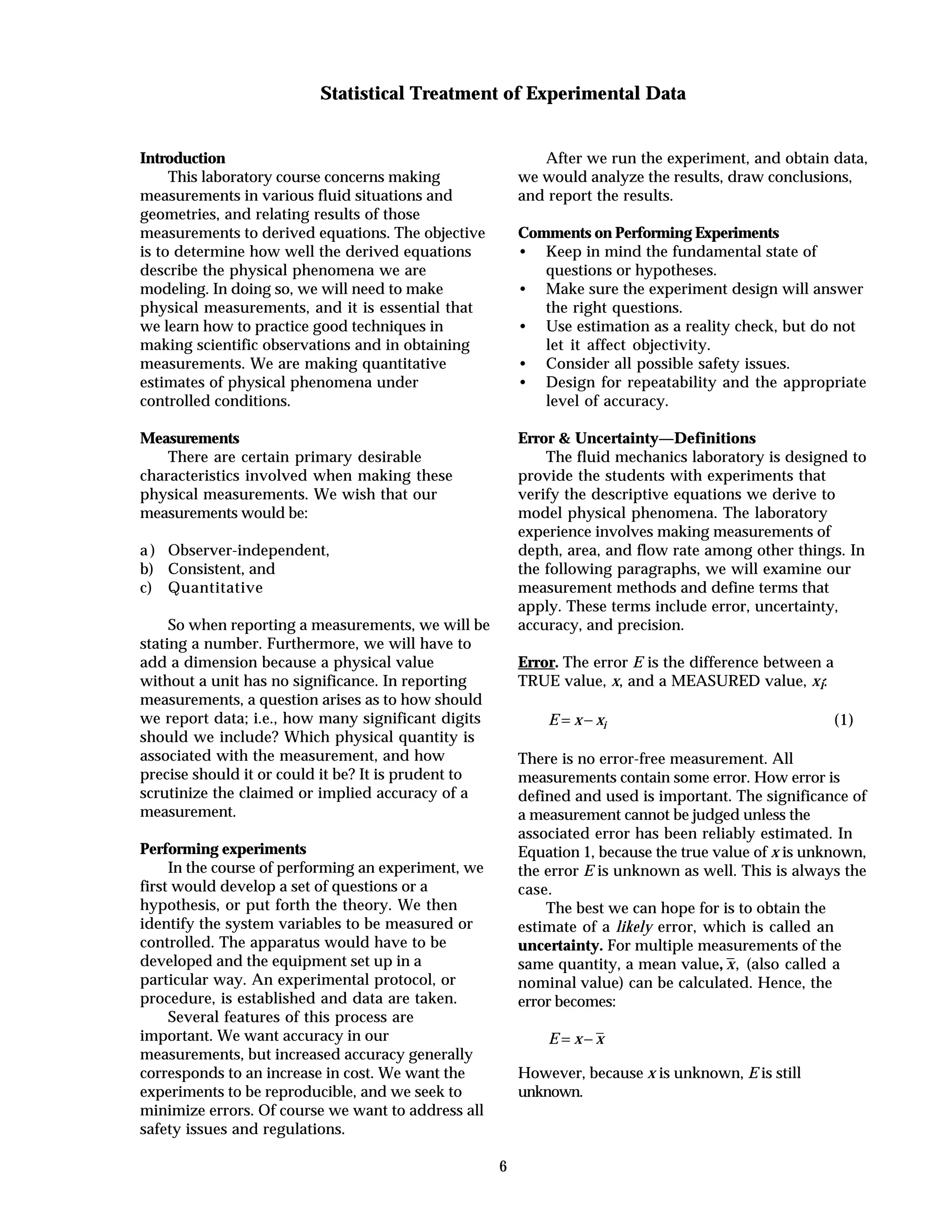

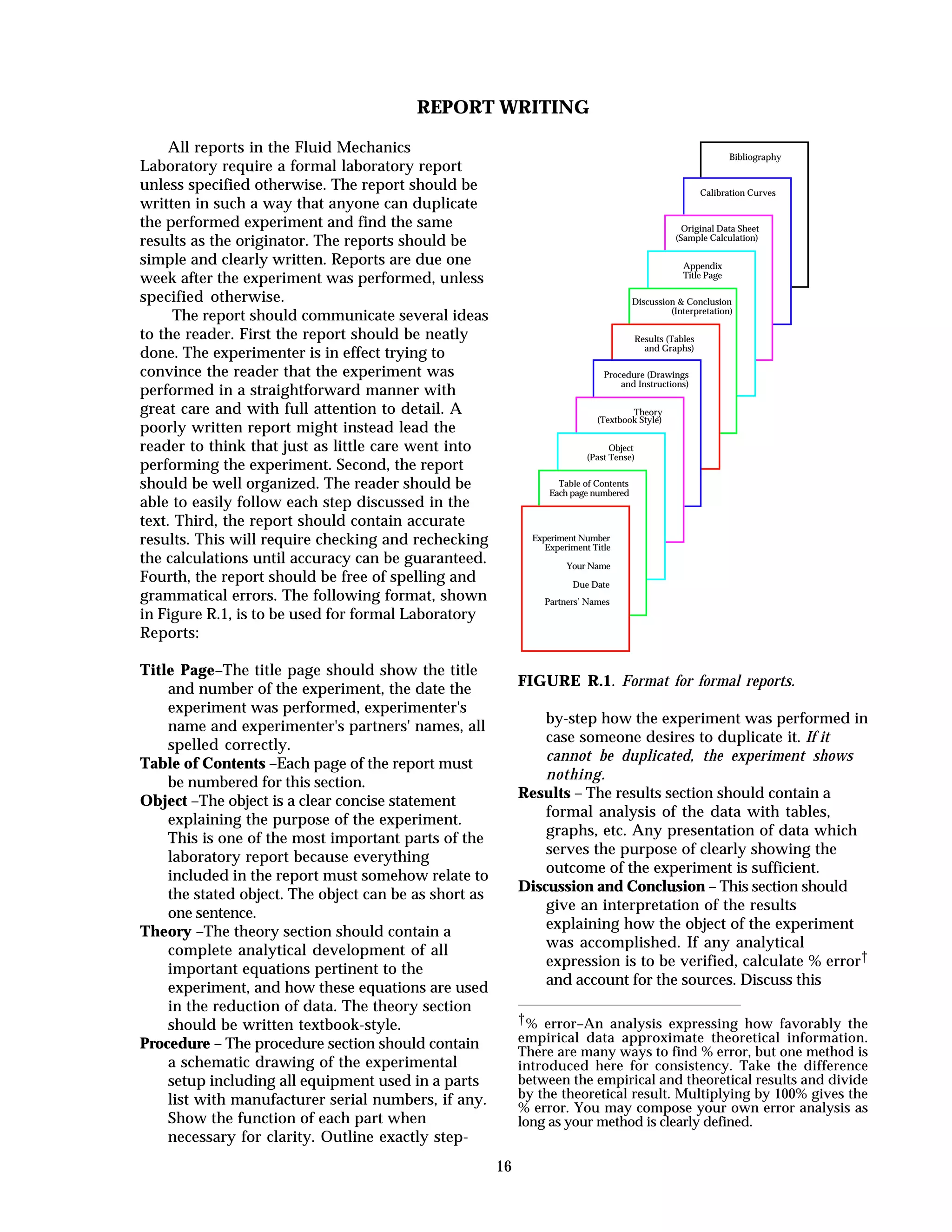

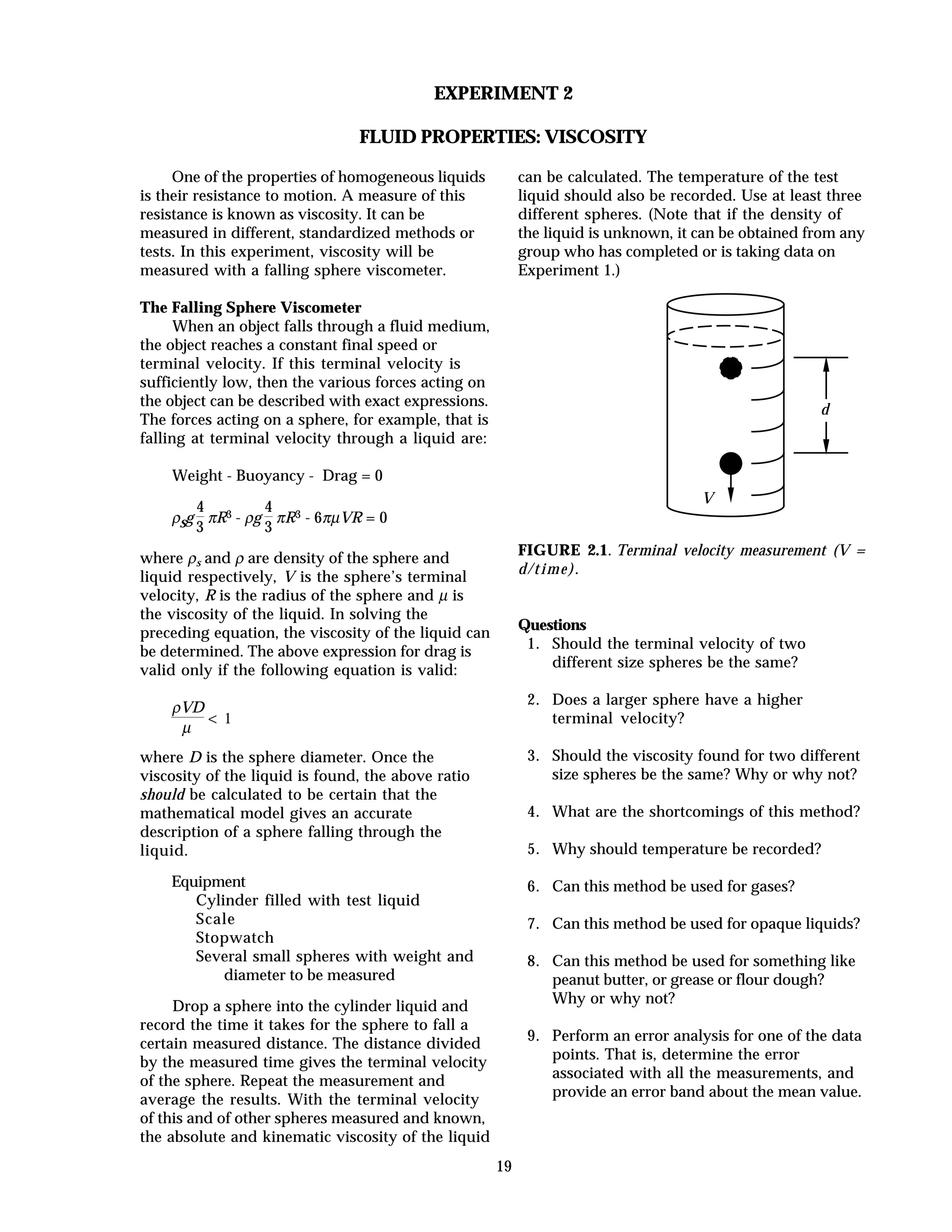

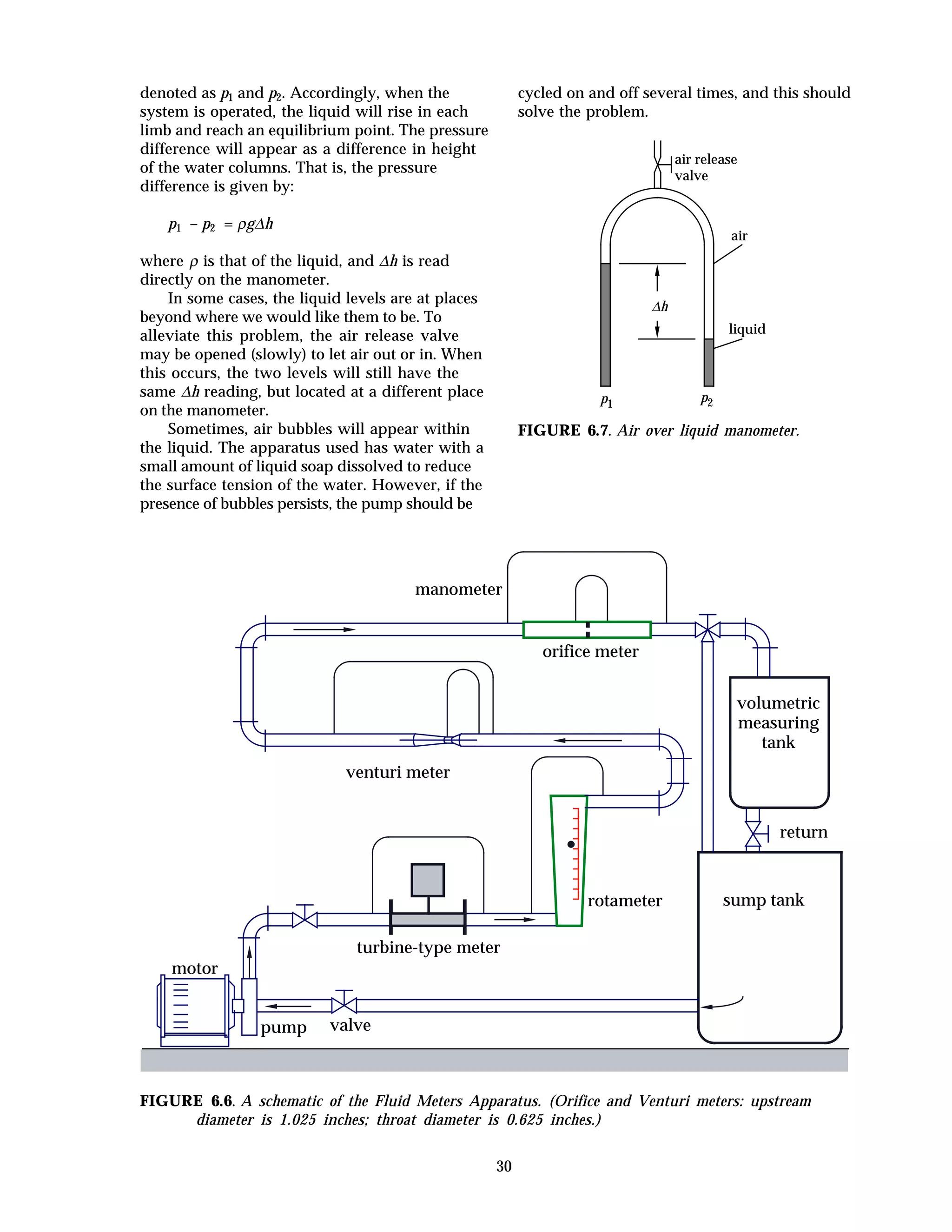

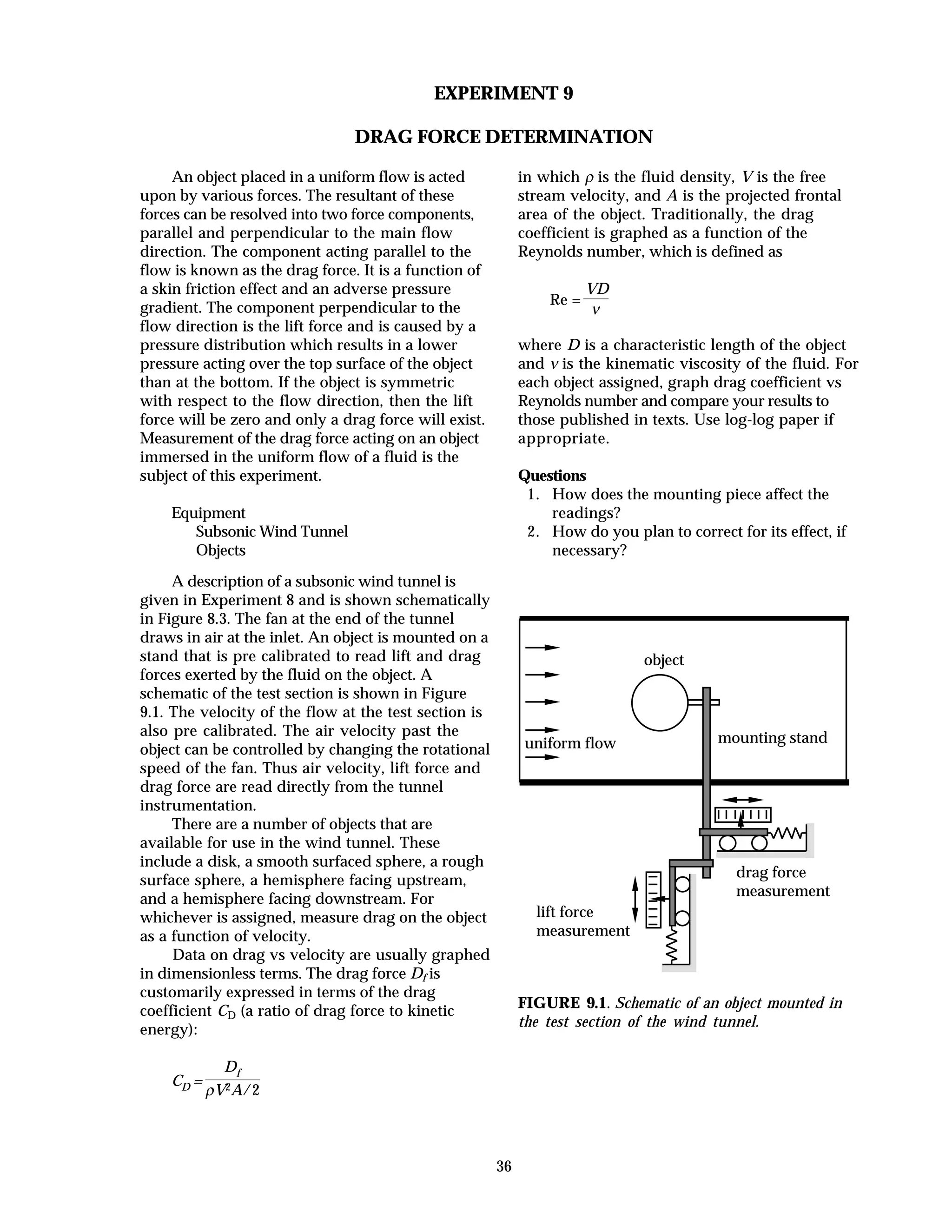

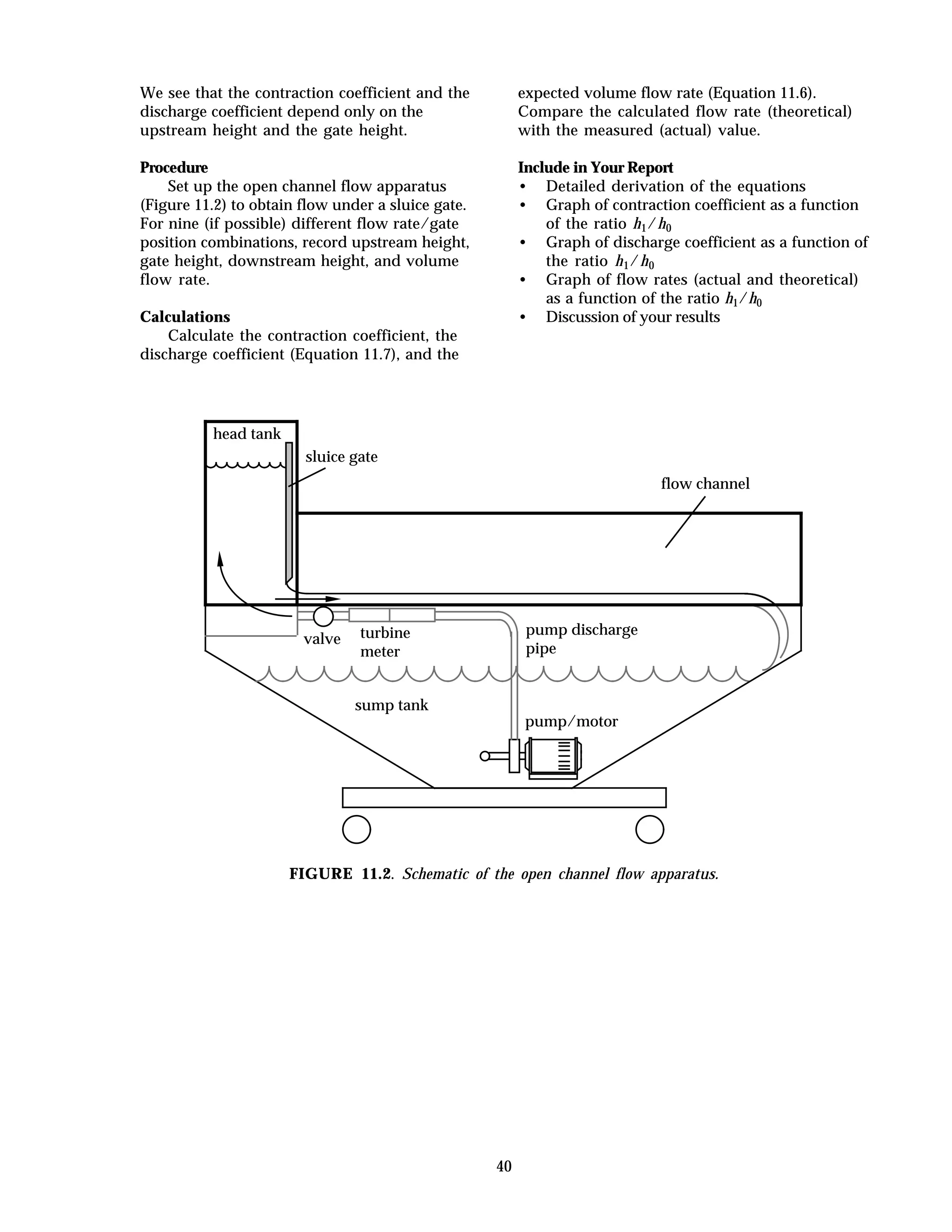

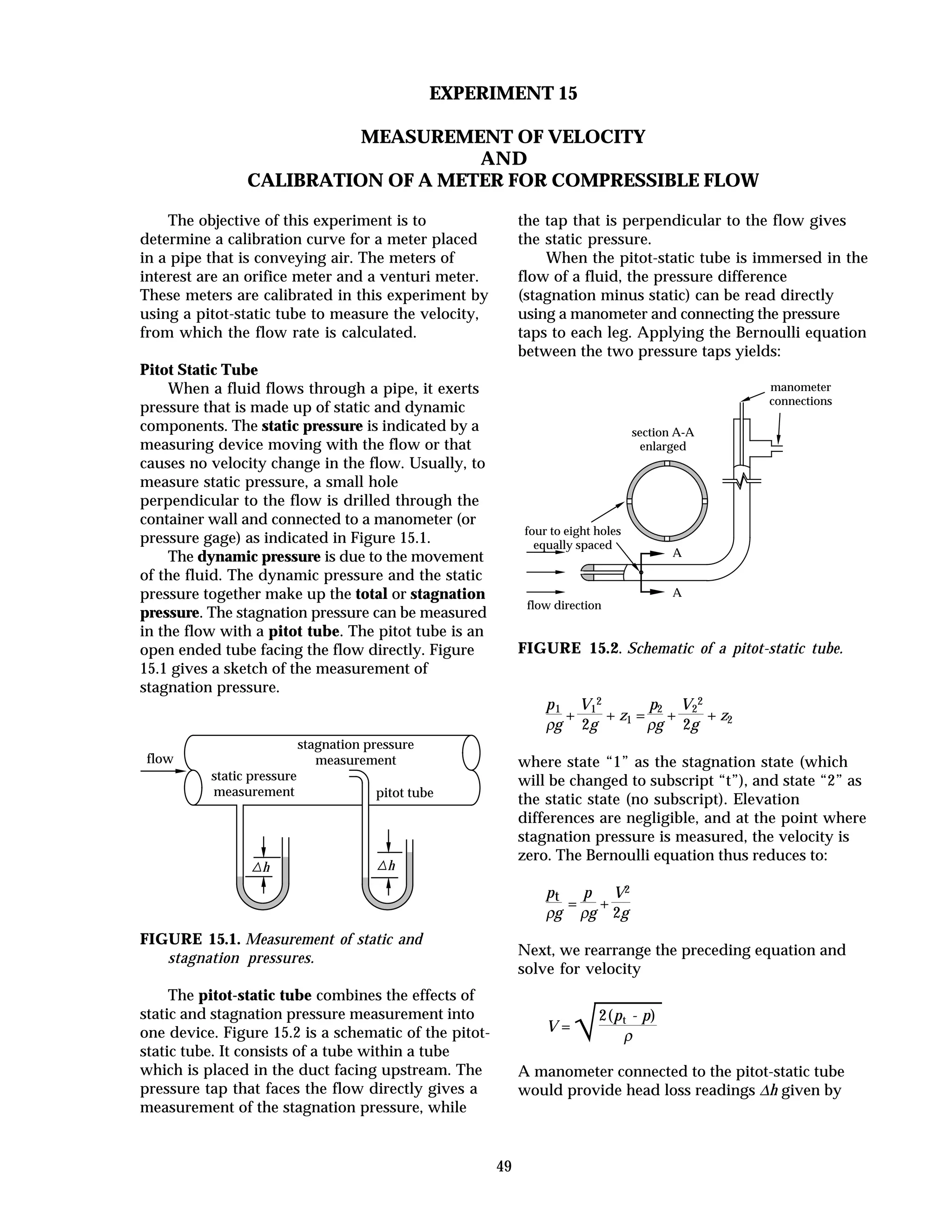

![62

EXPERIMENT 19

DESIGN OF EXPERIMENTS:

CALIBRATION OF AN ELBOW METER

There are many types of meters that can be

installed in a pipeline—venturi, orifice,

rotameter, and turbine-type. These meters can all

be calibrated to provide a reading of the volume

flow rate of fluid through the pipe.

An alternative, less expensive flow meter—

known as an elbow meter—can also be used. For an

existing pipeline containing elbows, an elbow

meter is perhaps the easiest meter to set up. All

that would be required is to drill and tap a couple

of holes in the elbow, and attach them to a

device for measuring pressure drop. Information

on an elbow meter is available from [1]. A sketch

of an elbow meter is shown in Figure 19.1

flow

D

R

45o

pressure

tap

FIGURE 19.1. Schematic of an elbow meter

showing pressure tap locations.

Installation. It is necessary to select an elbow in a

line where flow rate is to be measured. The

internal dimensions of R and D must be known for

the elbow of interest. Holes are drilled in specific

locations as shown to accept 1/8th nominal pipe

threads or something different if desired.

Pressure measurements are made to determine

the pressure drop that exists as well as the

corresponding flow rate.

Theory. The pressure measurement devices are

attached to the connectors and flow through the

pipe is initiated. The difference in pressure

between the tap locations is to be determined.

As given in [1], the flow rate through the

meter can be calculated with:

Q = A K

√

R

D

∆ p

ρ

where

A = cross sectional area = πD2/4 in ft2

K= 1 -

6.5

√Re

= correction factor (19.1)

Re = Reynolds number = ρVD/µ

104 ≤ Re ≤ 106

ρ = fluid density in slug/ft3

µ = fluid viscosity in lbf·s/ft2

∆p = pressure drop in lbf/ft2

D = diameter in ft

R = radius of elbow in ft

Sample Calculation. Show how flow rate is

calculated using a 4 nominal schedule 80 short

radius elbow meter. Pressure is measured with a

manometer. Water is the working fluid.

Solution: For a 4 nominal, short radius elbow we

have [2]:

R = 4 in. = 0.333 ft D = 0.3198 ft

We calculate

A =

πD2

4

=

π(0.3198)2

4

= 0.0803 ft2

For water,

ρ = 1.94 slug/ft3 µ = 1.9 x 10-5 lbf·s/ft2

A calibration curve is one that relates the volume

flow rate through the meter to the pressure drop,

using whatever units are convenient. We are

calculating the calibration results for only one

data point in such a curve. In this example, we

measure flow rate in gpm, and because we are

using a manometer, we express pressure drop in](https://image.slidesharecdn.com/fluidslabmanual2-140524214604-phpapp01/75/Fluids-lab-manual_2-62-2048.jpg)

![63

terms of inches of water. A sample calculation for

a flow rate of, say, 150 gpm is as follows. We

have

Q = 150 gpm (2.229 x 10-3) = 0.334 ft3/s

The flow velocity then is

V =

Q

A

=

0.334

0.0803

= 4.16 ft/s

To find ∆p, we must first find K which in turn

depends on Reynolds number:

Re=

ρVD

µ

=

1.94(4.16)(0.3198)

1.9 x 10-5 = 1.36 x 105

Then

K = 1 -

6.5

√Re

= 1 -

6.5

√1.36 x 105

= 0.982

For an elbow meter,

Q = A K

√

R

D

∆ p

ρ

Rearranging and solving for ∆p gives

∆p = ρ

Q

A K

2 D

R

(19.2)

Substituting

∆p = (1.94)

0.334

0.0803(0.982)

2 0.3198

0.333

or ∆p = 33.4 lbf/ft2

Now in terms of a column of water,

∆h =

∆p

ρg

=

33.4

1.94(32.2)

= 0.534 ft of water

or ∆h = 6.41 in. of water

For calculations of this type on an elbow that has

not been tested in the laboratory, the result is

accurate to within ± 4%. That is, for a reading ∆h

of 6.41 in. of water, the flow rate can be as high

as 156 gpm or as low as 144 gpm. Note that a

manometer is not readable to the nearest

hundredth of an inch. Typically a reading will be

to the nearest tenth of an inch.

So based on the results here, one data point on

the calibration curve is:

∆h = 6.4 in of water Q = 150 gpm

Calibration. In the preceding calculation, note

the dependence of the results on having an

equation for the correction factor K (Equation

19.1). The equation for K was derived from

theoretical considerations [1], but it is desirable

to have experimental results to determine a

“better” relationship for it. We could use

Equation 19.2 with experimental data to

determine K, which is the subject of this exercise.

Thus, if we had an apparatus that is set up

and ready to use, we could measure flow rate Q,

determine R and D from a handbook [2], calculate

A, and reduce Equation 19.2 to:

∆p = (a known constant) x

Q

K

2

(19.3)

Then with the apparatus, we could obtain ∆p vs

Q for a number of data points. Using Equation

19.3, we could then calculate K.

Experiment Design

1. Design an apparatus for making measurements

on an elbow meter. It is desired to have the

capability of making measurements on 3/4, 1 and

1 1/2 inch line sizes/elbows. A sketch of the

apparatus is required, showing:

a) what fluid is to be used

b) the prime mover for pumping the fluid

c) where the fluid is to be stored

d) an accurate method for determining actual

flow rate

2. Write a procedure for the operator(s) to follow

in order to obtain the desired data.

3. Write a theory section that leads the reader

through a sample calculation and shows

specifically how the correction factor K is

determined.

4. How many data points should be obtained so

that K can be determined with 95% confidence?

References

[1] Fluid Meters: Their Theory and Application,

6th edition, 1971, ASME, New York, page 75.

[2] (Perry’s Chemical Engineering Handbook, pg.

6-57.](https://image.slidesharecdn.com/fluidslabmanual2-140524214604-phpapp01/75/Fluids-lab-manual_2-63-2048.jpg)