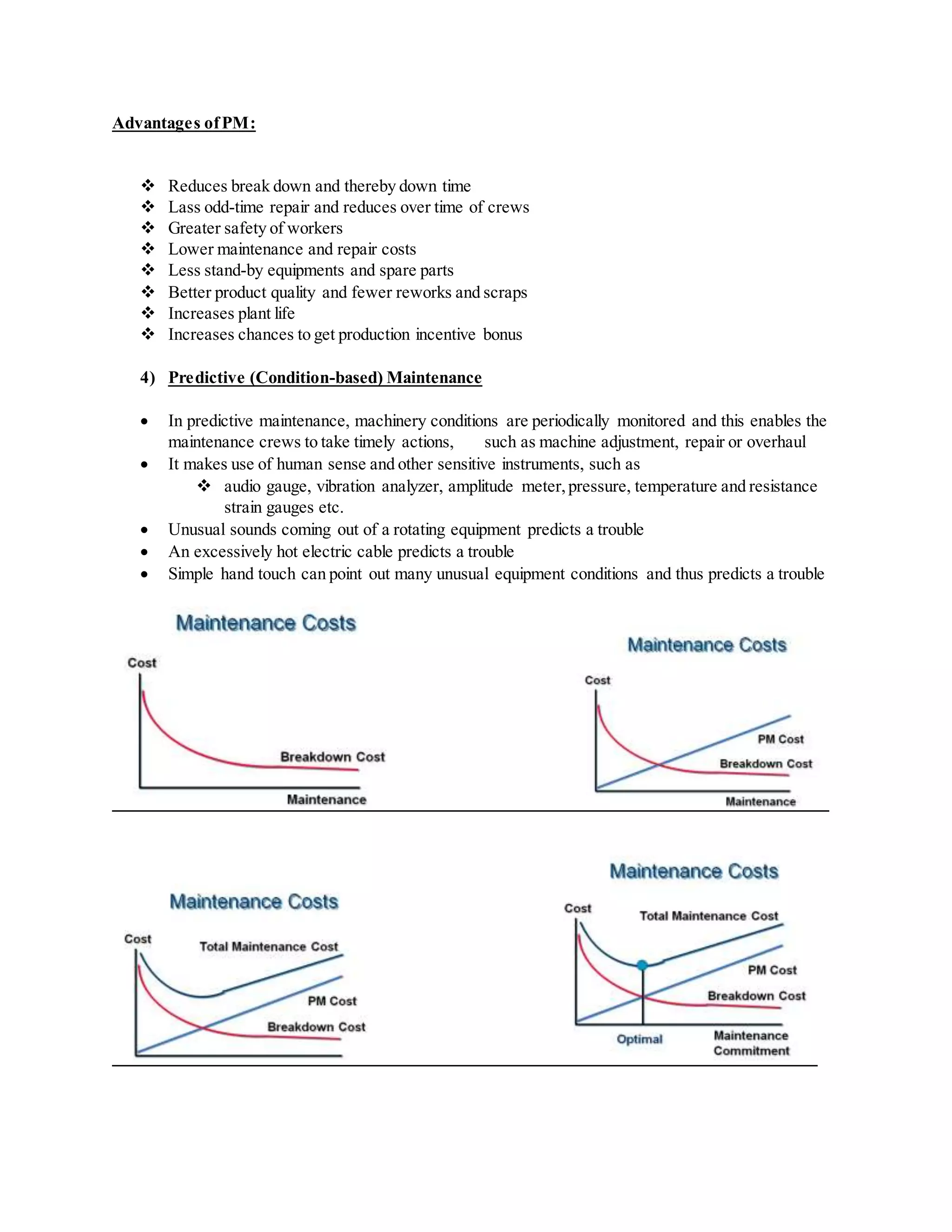

This document provides an introduction to maintenance. It discusses the importance of maintenance for safety, productivity, and avoiding costly failures. It outlines different types of maintenance including corrective, scheduled, preventive, and predictive maintenance. Preventive maintenance aims to perform minor repairs and inspections periodically to reduce unexpected breakdowns. The benefits of preventive maintenance include reducing downtime, repair costs, and improving safety, product quality, and plant life. The document also provides an example of calculating the number of repair crews needed based on machine breakdown and repair rates.