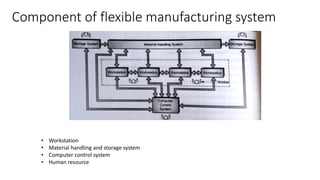

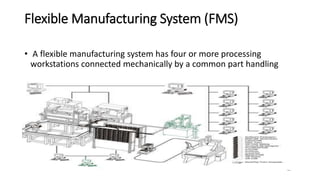

This document discusses flexible manufacturing systems (FMS). It defines an FMS as an automated machine cell consisting of a group of processing workstations interconnected with an automated material handling and storage system. The key components of an FMS are workstations, material handling/storage systems, computer control systems, and human resources. An FMS provides various types of flexibility including flexibility of product variety, production volume, delivery time, material handling, operations, expansion, and markets. The document then provides a brief history of FMS and classifications including single machine cells, flexible manufacturing cells, and flexible manufacturing systems.