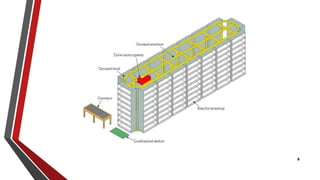

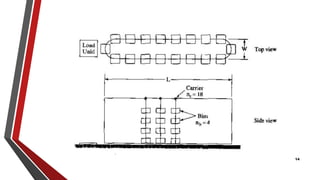

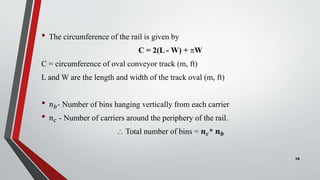

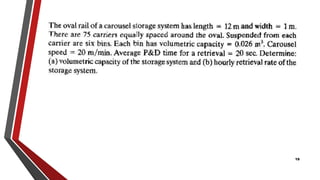

The document discusses carousel storage systems, which consist of bins on a revolving conveyor that facilitate load/unload operations. It classifies these systems into horizontal and vertical carousels, detailing their structures, control mechanisms, and applications, including manual and computer controls for increased automation. Additionally, it includes engineering analyses for throughput and cycle time calculations related to storage and retrieval operations.