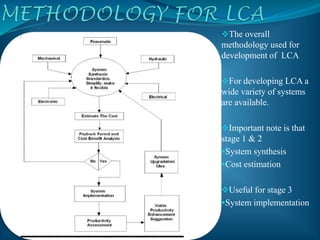

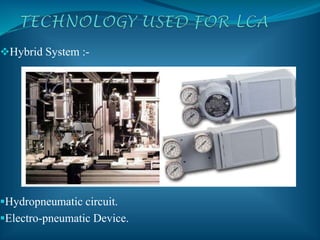

The document discusses low cost automation (LCA), a technology that enhances existing manufacturing processes using standard components. It explores various systems used in LCA, including mechanical, pneumatic, hydraulic, electric, and hybrid systems, emphasizing their features and applications. Additionally, it addresses the importance of good manufacturing practices in industries like pharmaceuticals and the challenges in implementing efficient batch process management and control.