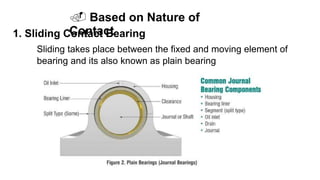

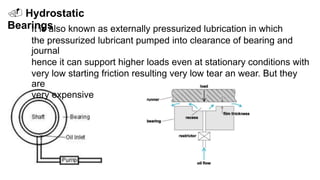

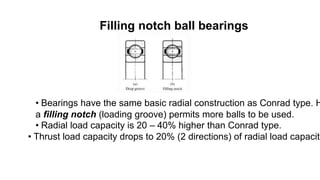

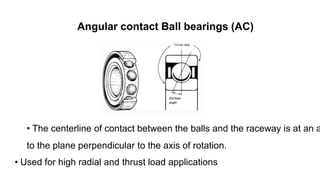

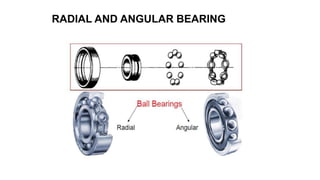

The document discusses the classification and types of bearings, including radial and thrust bearings, sliding contact, and rolling contact bearings. It highlights the characteristics and applications of journal bearings, such as hydrodynamic and hydrostatic bearings, and various types of rolling bearings including ball and roller bearings. Additionally, it covers factors affecting bearing performance, such as load, speed, lubrication, and the implications for design and manufacturing.