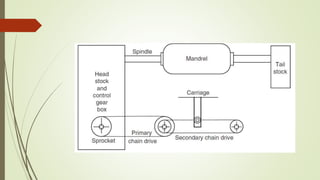

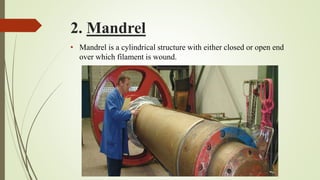

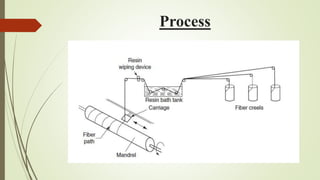

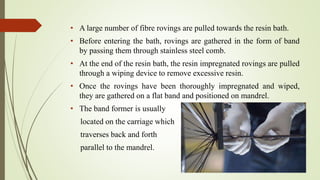

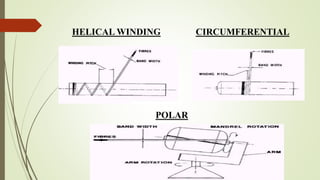

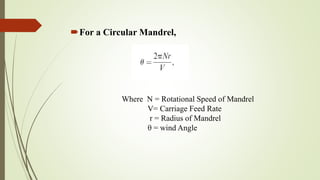

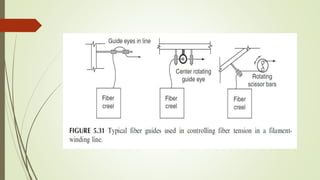

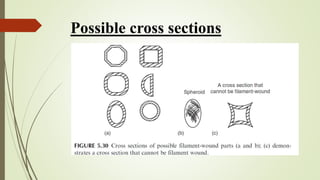

Filament winding is a manufacturing technique used to create cylindrical structures like pressure vessels by tension-winding fiber strands around a rotating mandrel. The process can utilize materials such as glass, carbon, and various resins, with parameters affecting fiber tension, wet-out, and material properties. While it offers advantages like high reproducibility and fiber orientation, disadvantages include potential defects and challenges in mandrel extraction.