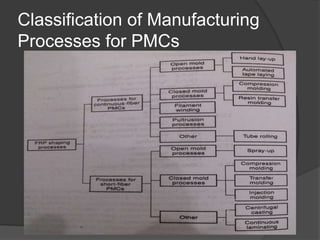

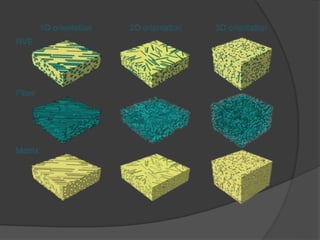

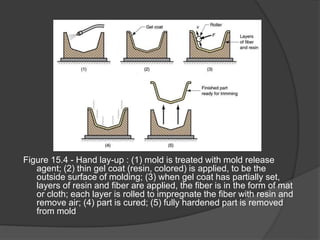

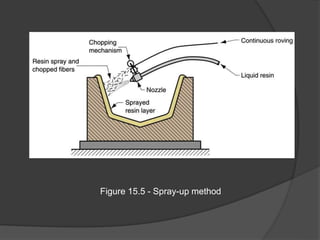

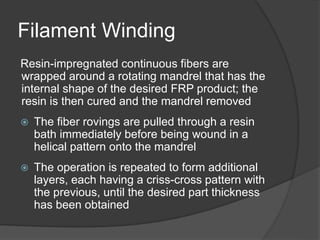

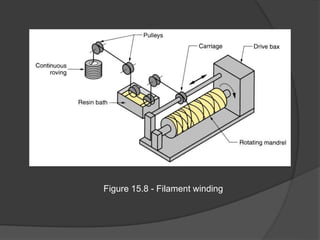

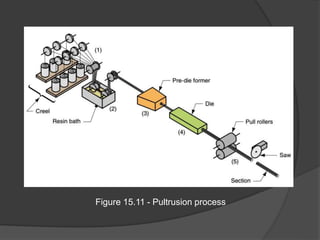

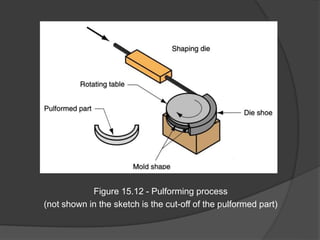

This document discusses various processes for shaping polymer matrix composites (PMCs). It begins by describing the typical starting materials for PMCs as polymers and reinforcing agents like fibers, particles or flakes. The document then covers open mold processes like hand lay-up and spray-up, closed mold processes like compression and transfer molding, and continuous processes like filament winding, pultrusion and pulforming. Each process combines the matrix and reinforcement in different ways to produce composite parts in open or closed molds. The document provides an overview of the key PMC shaping techniques.