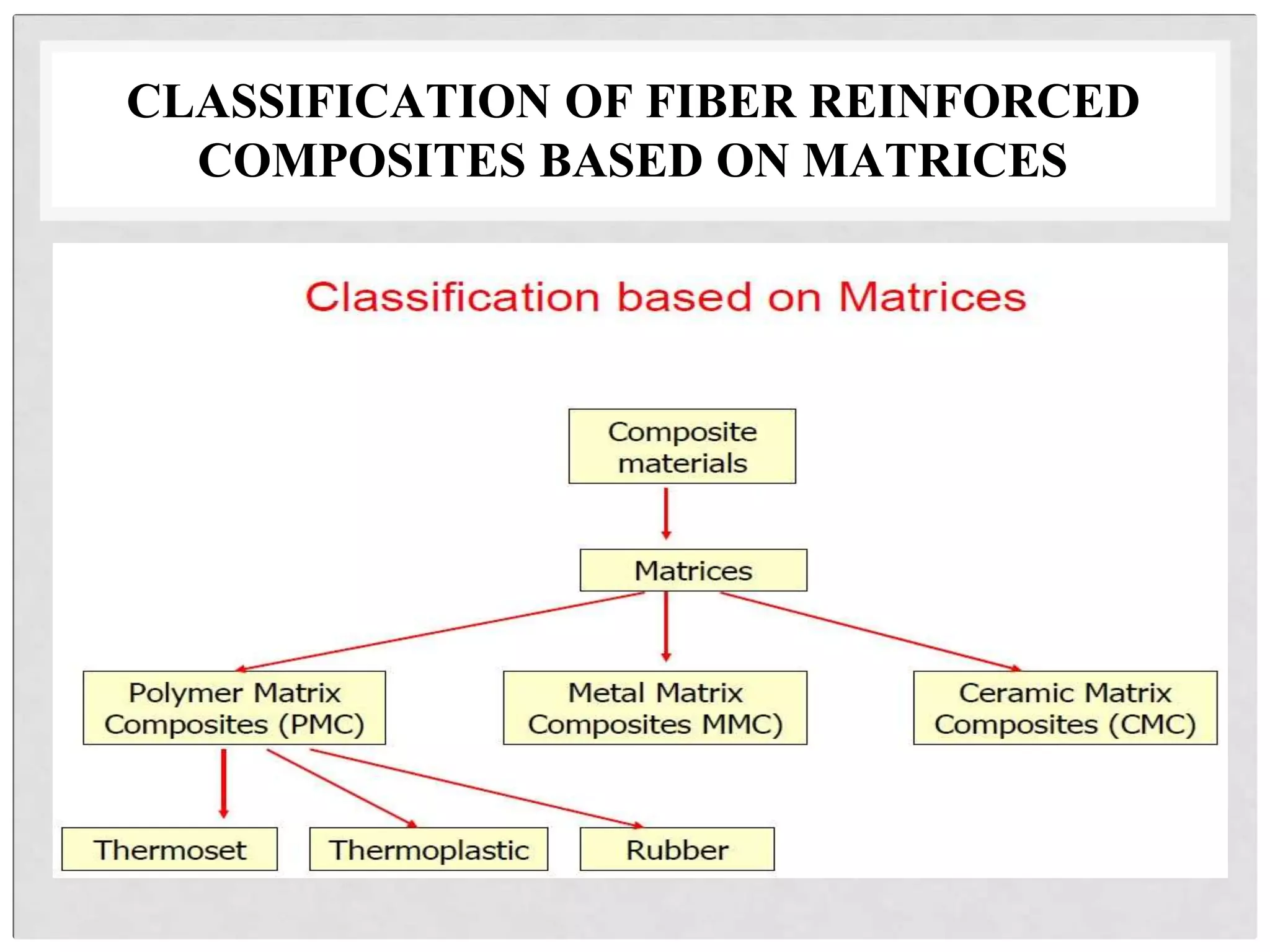

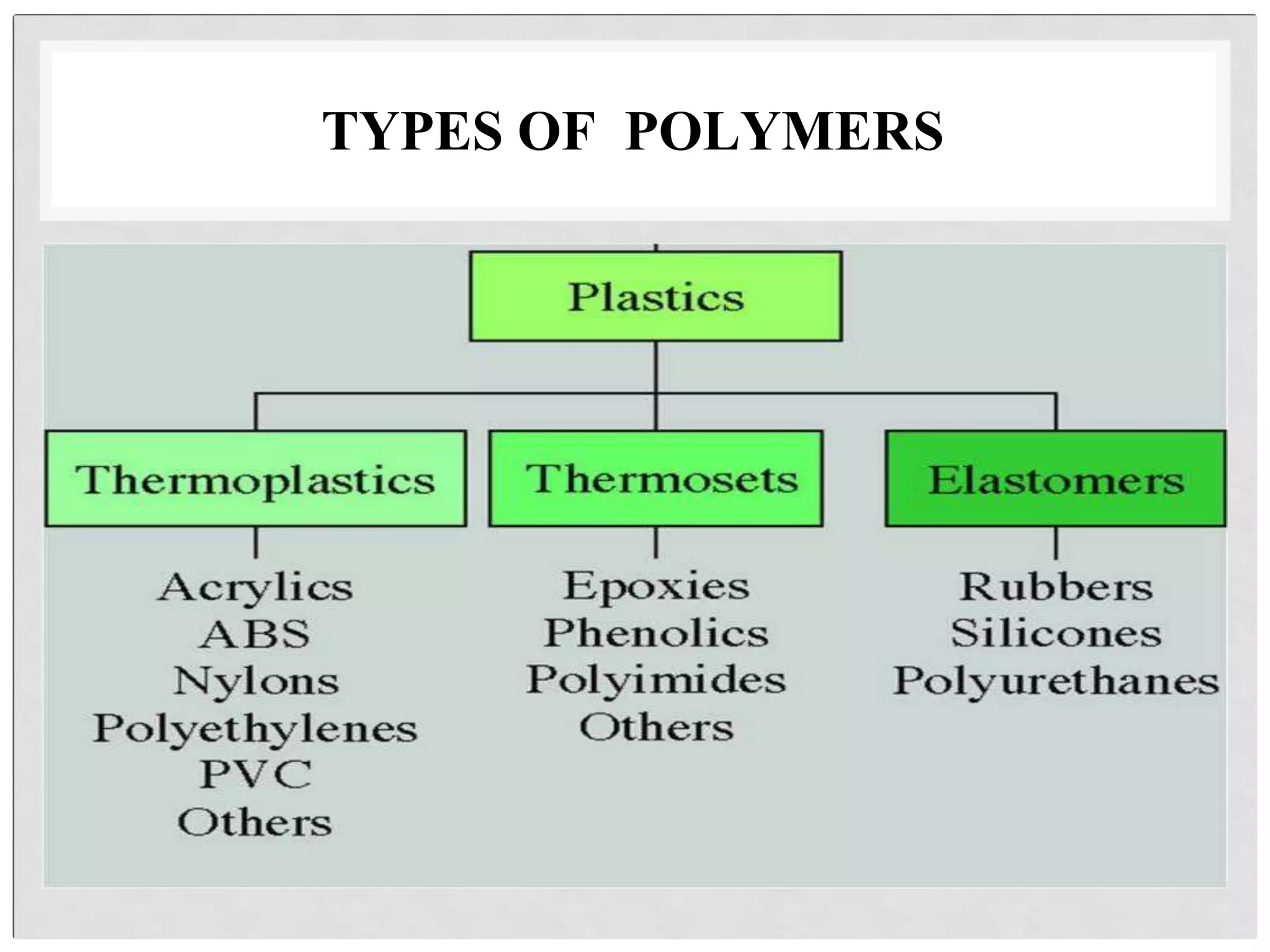

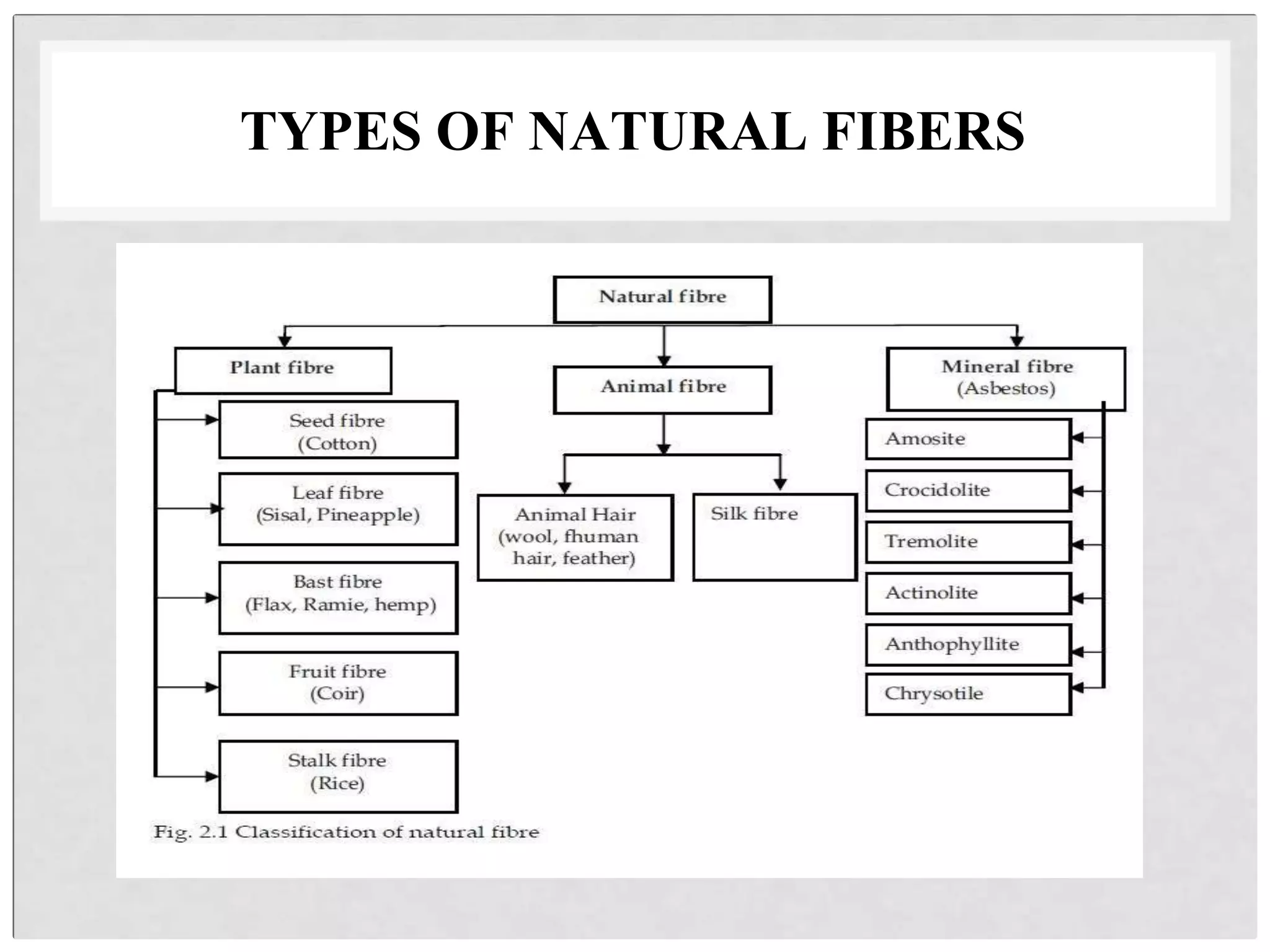

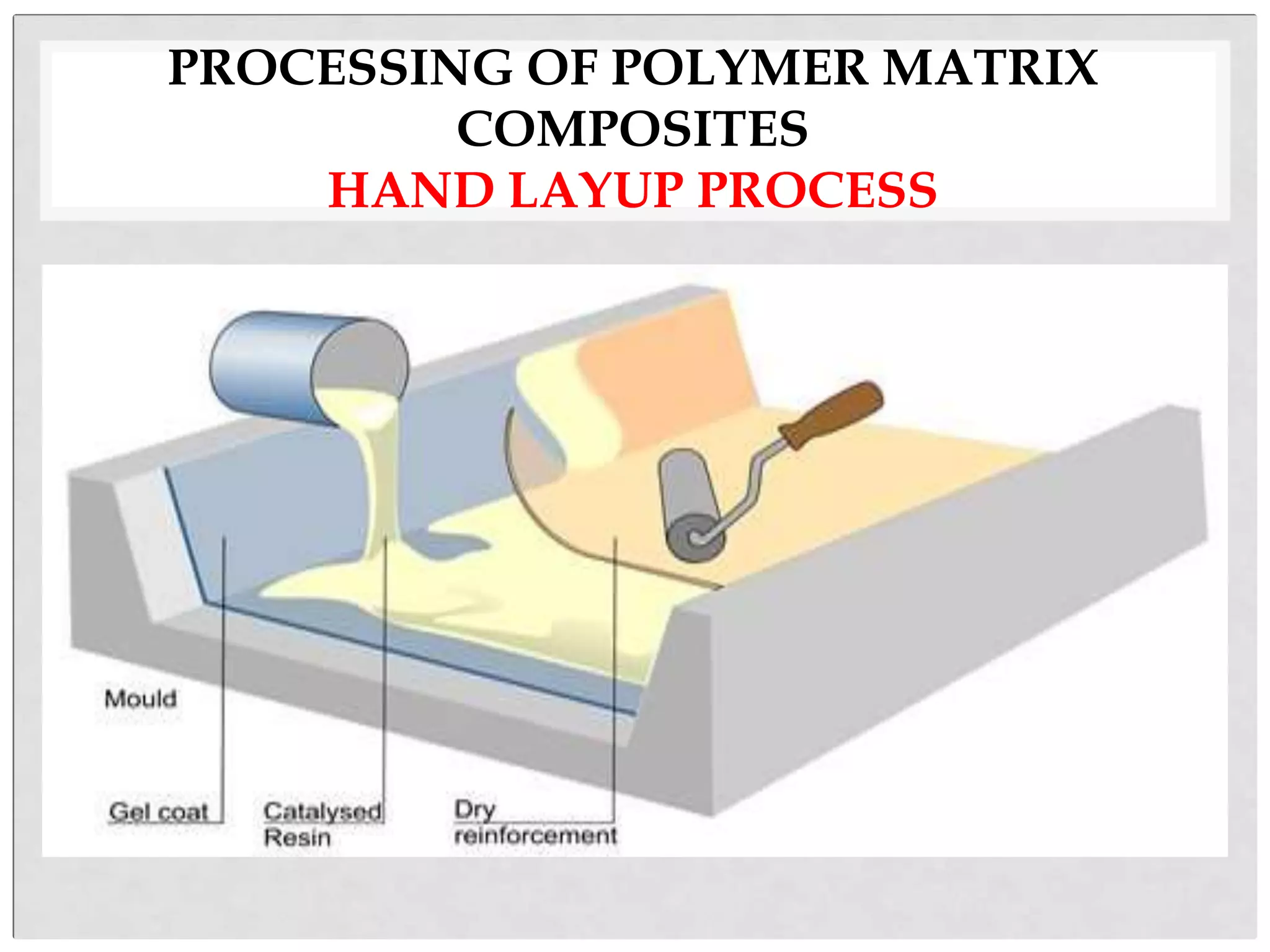

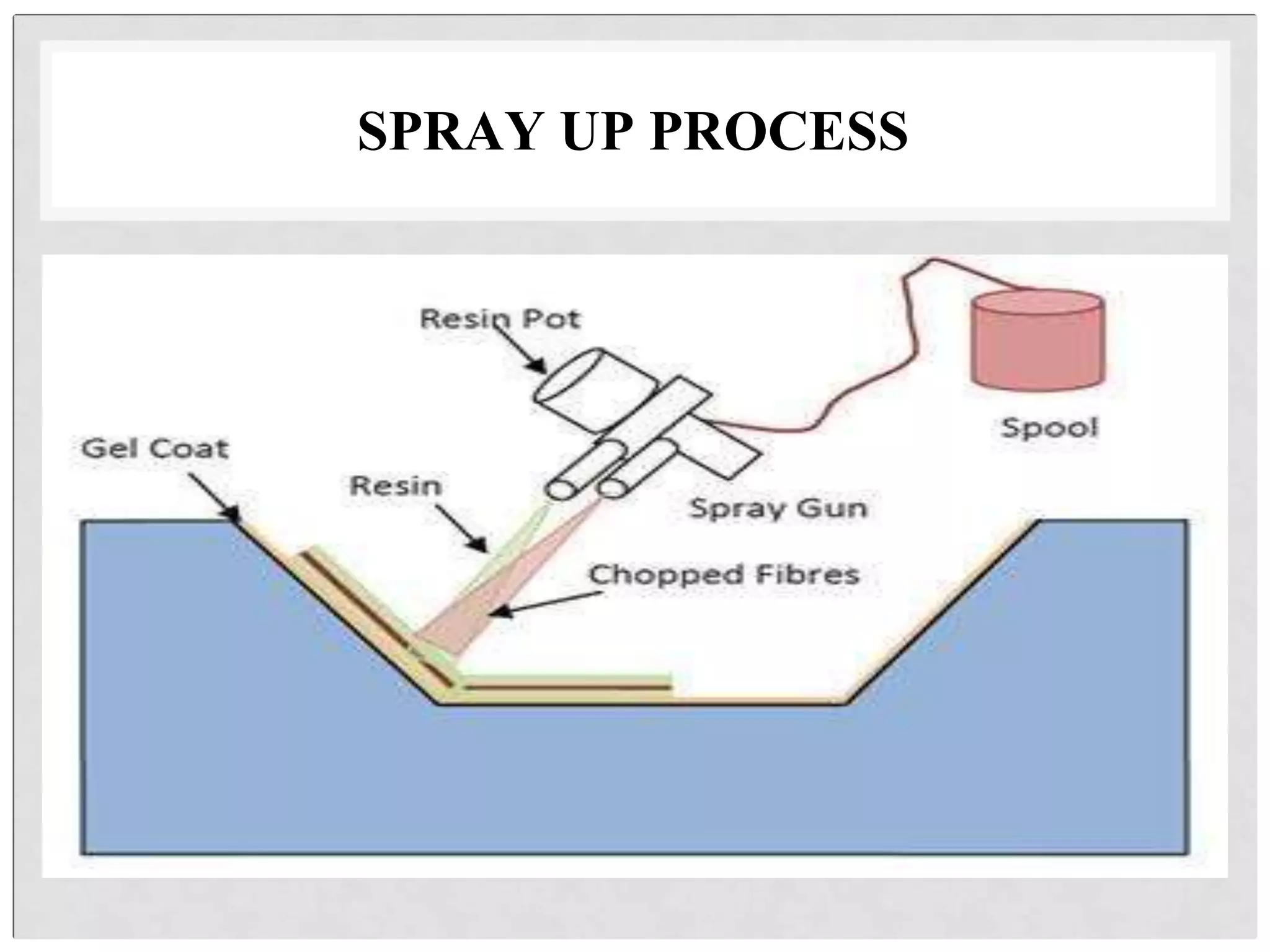

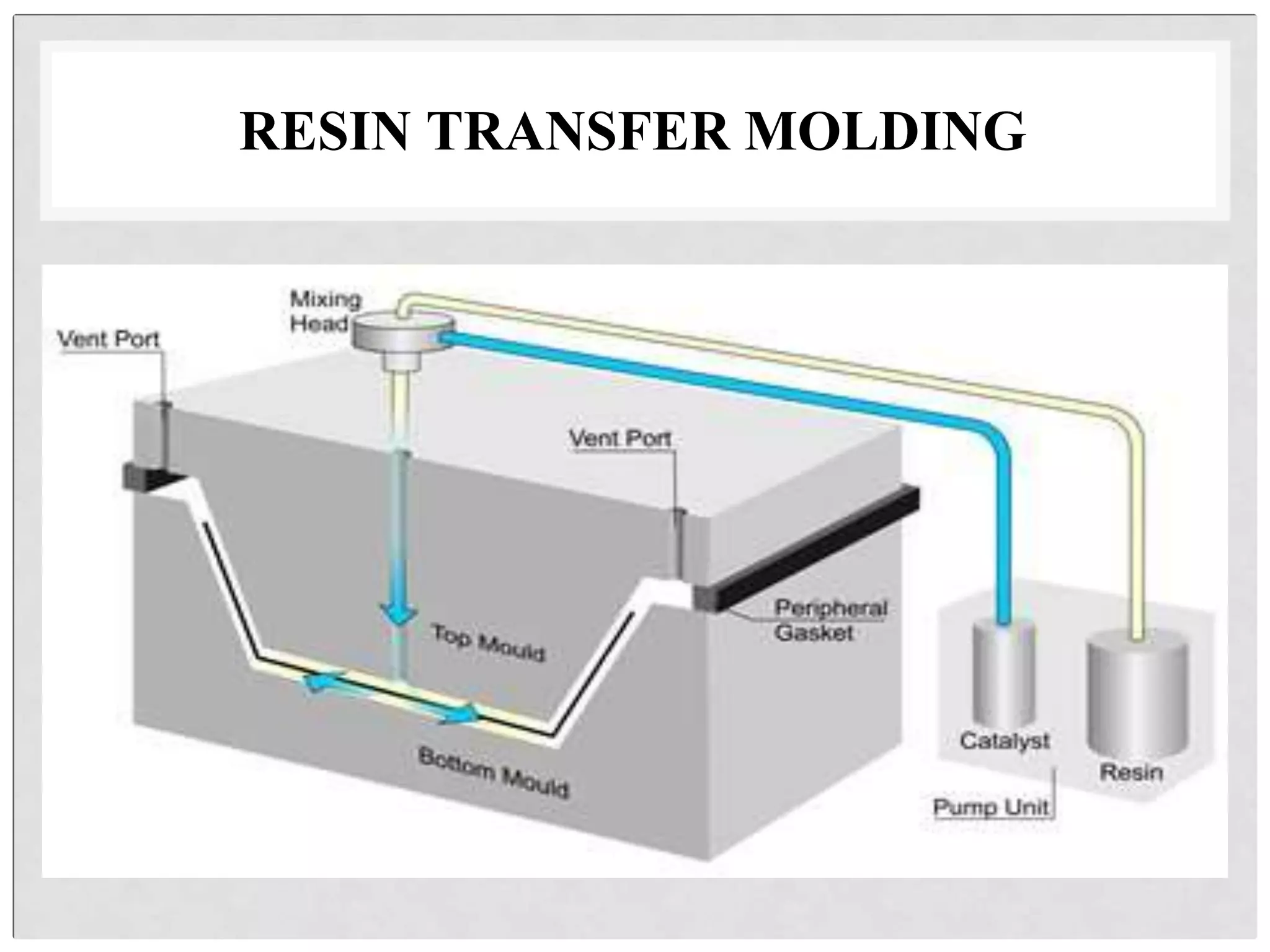

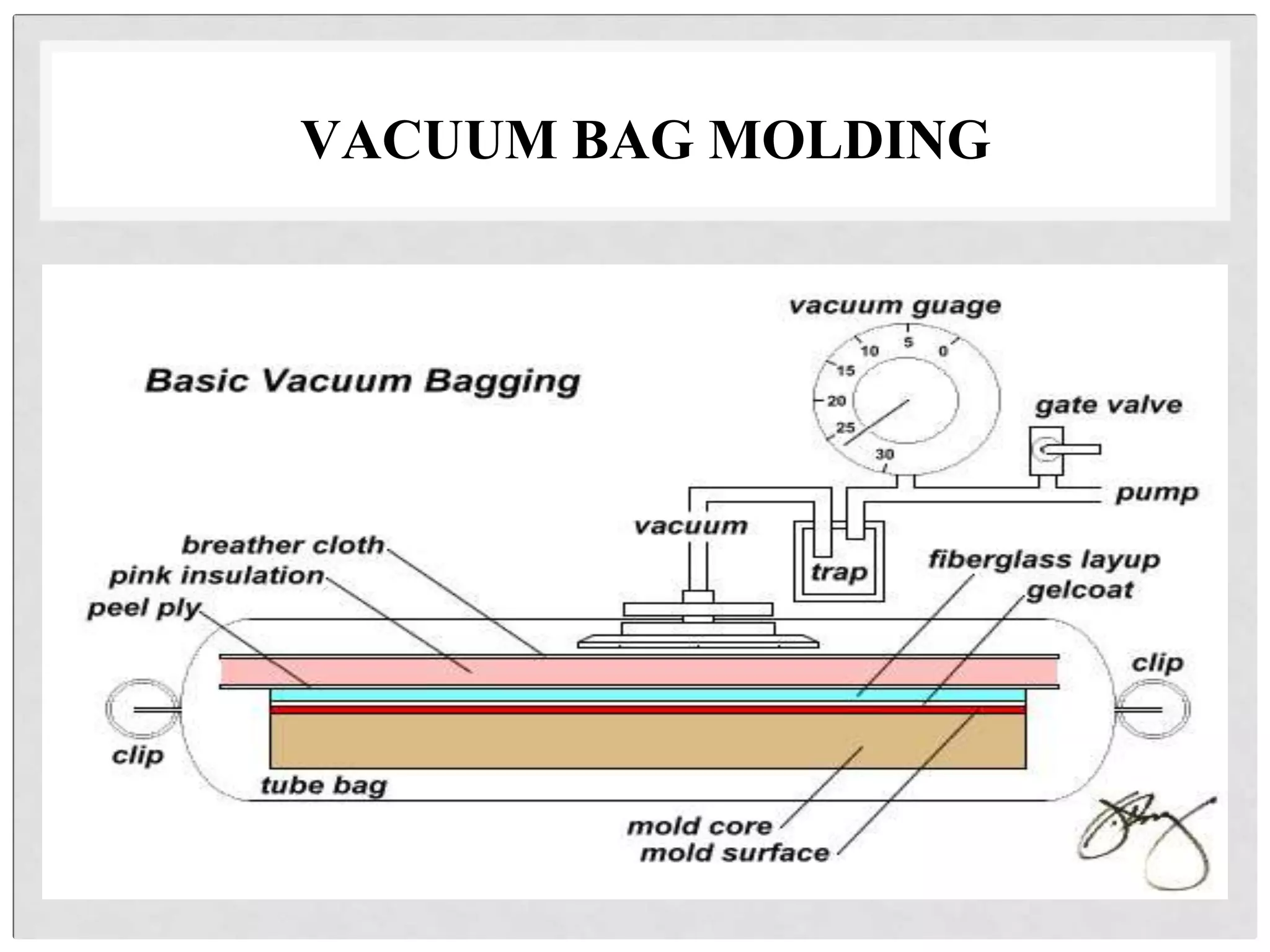

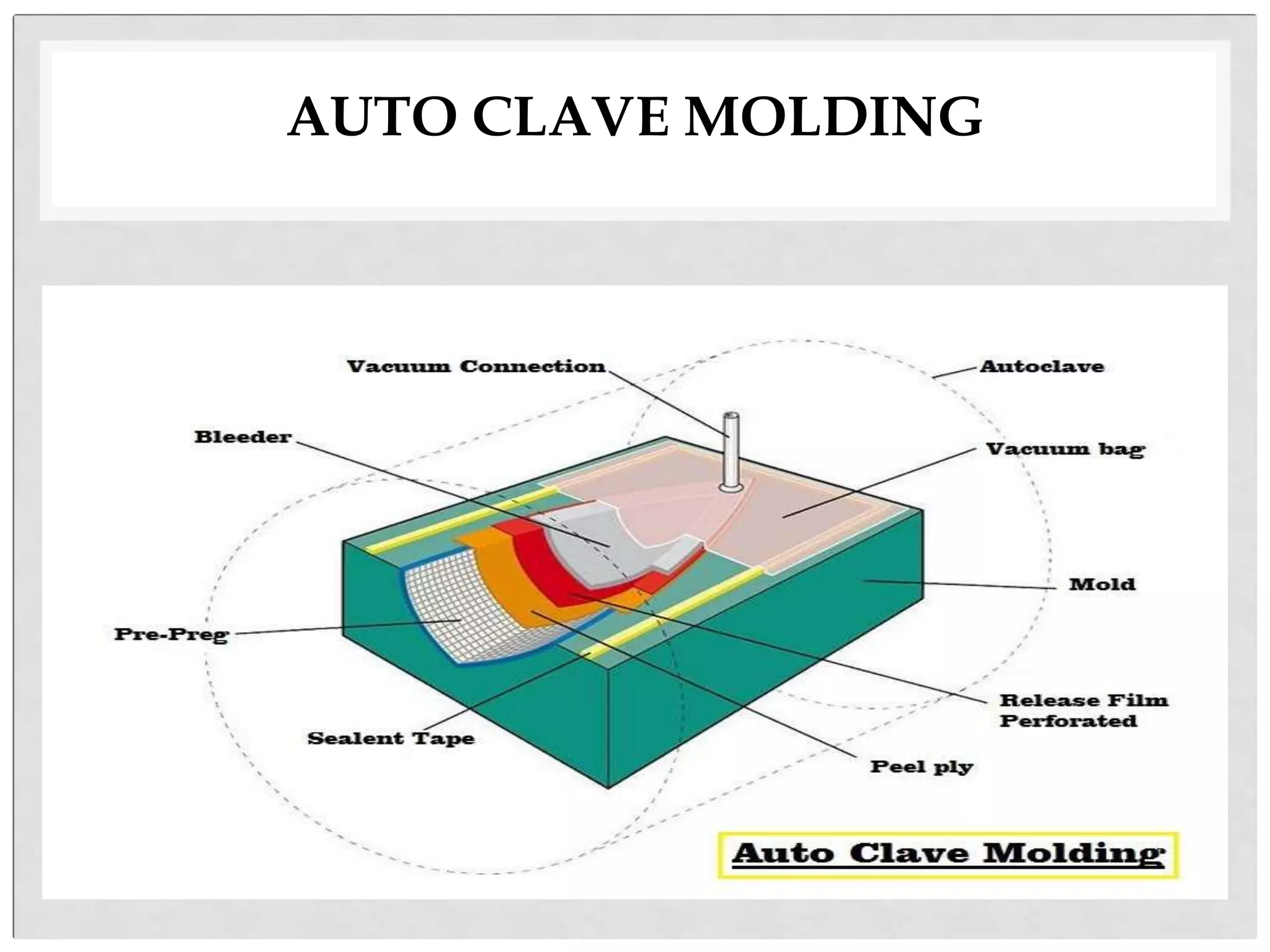

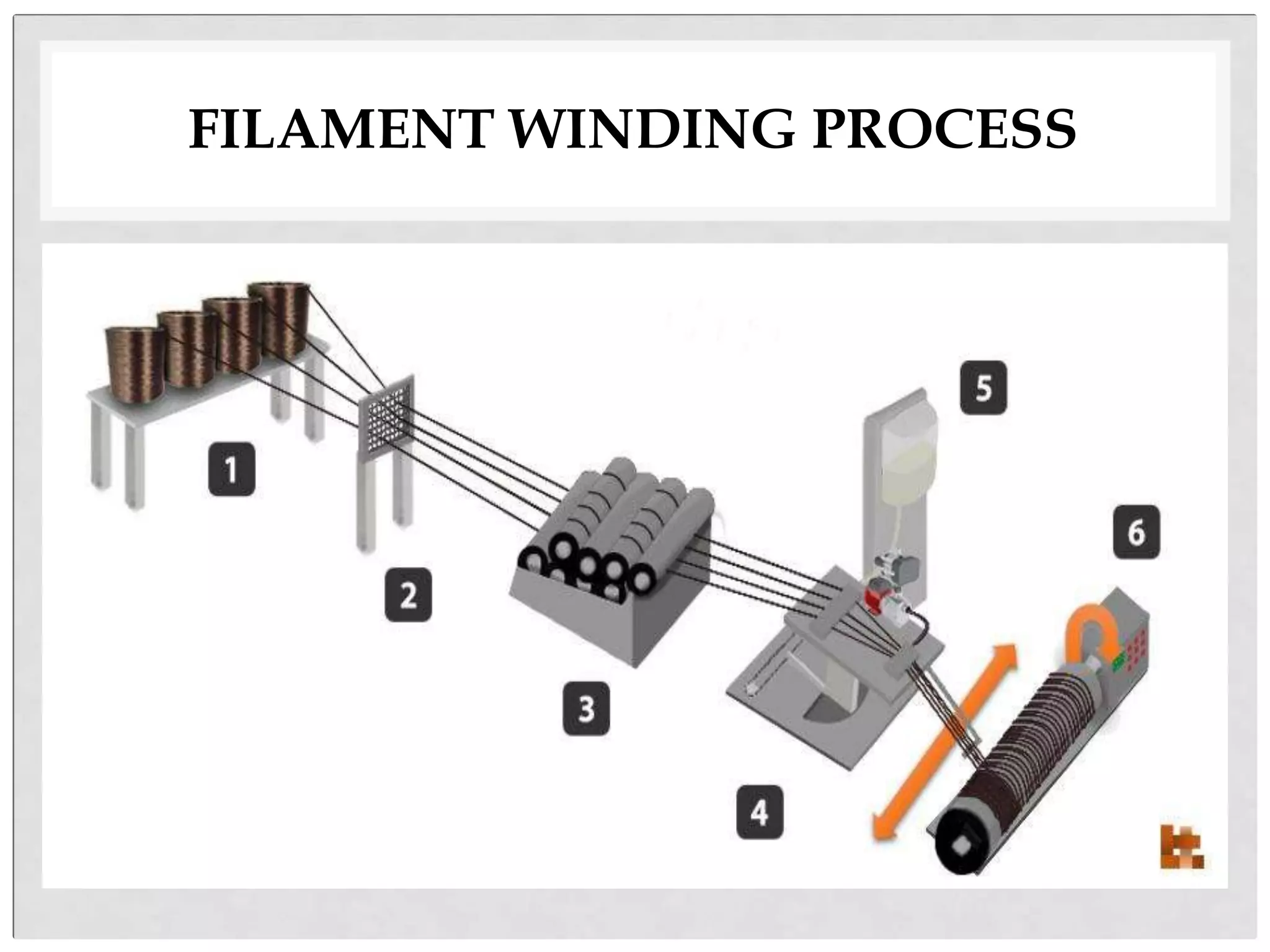

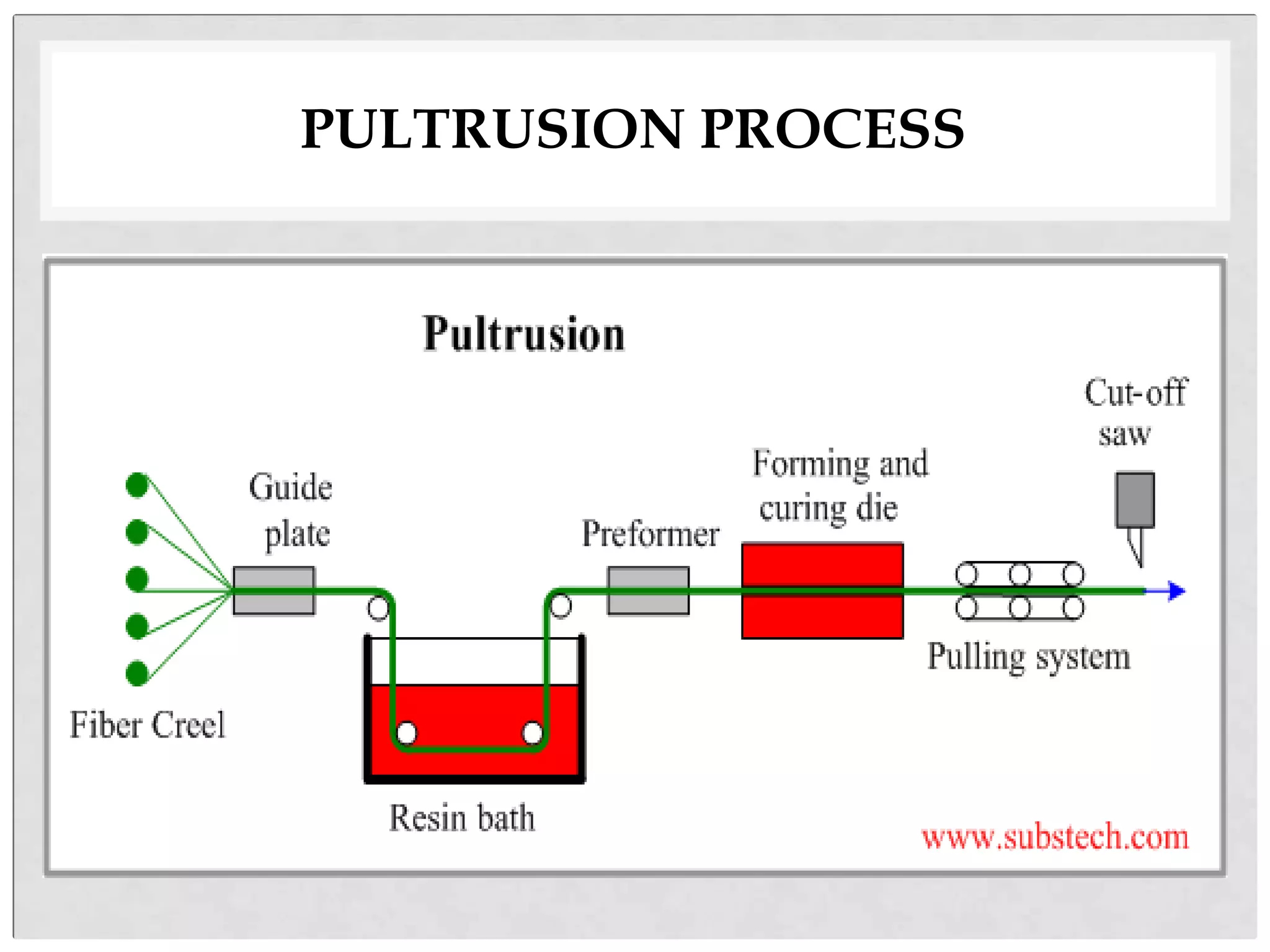

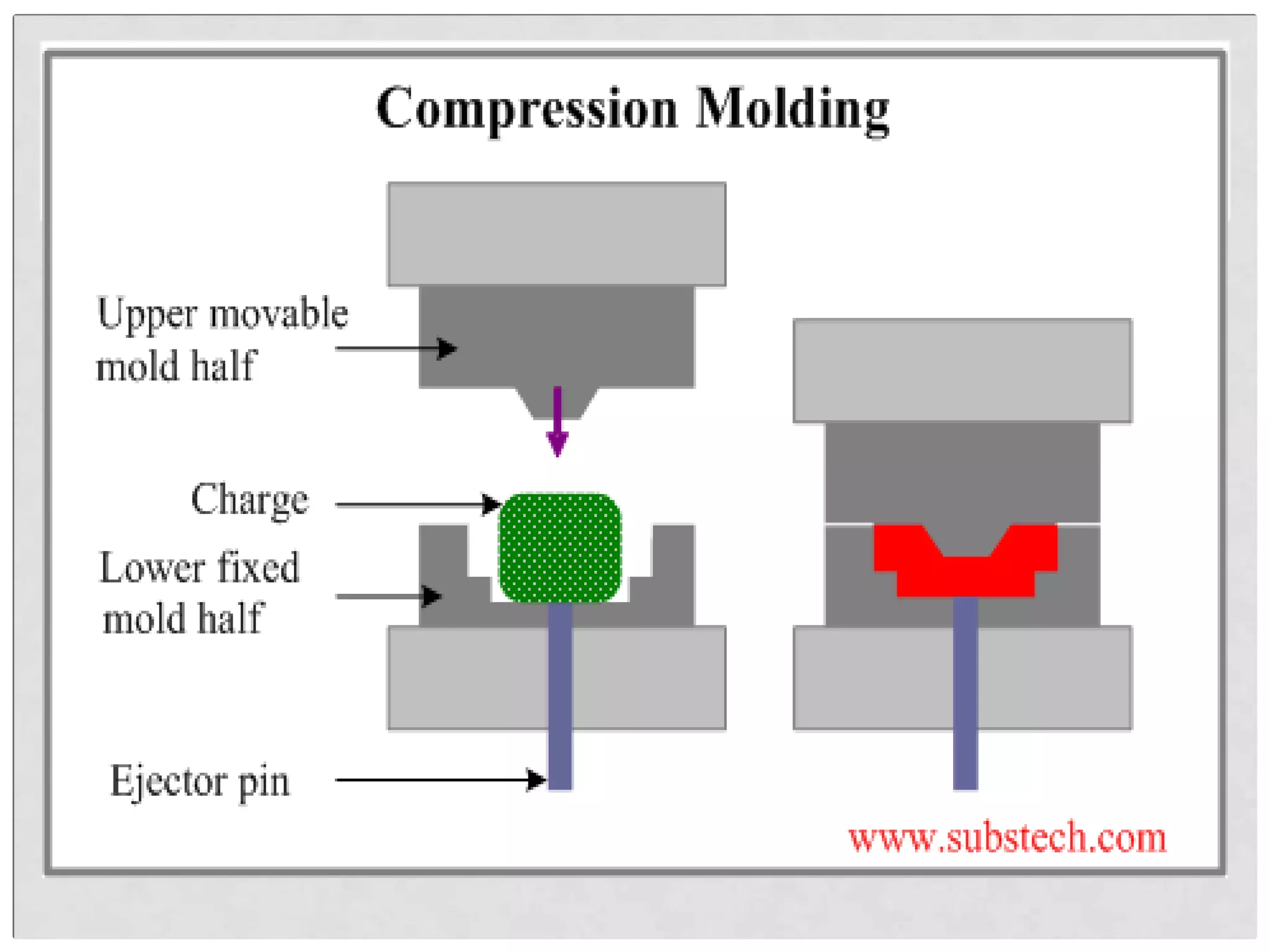

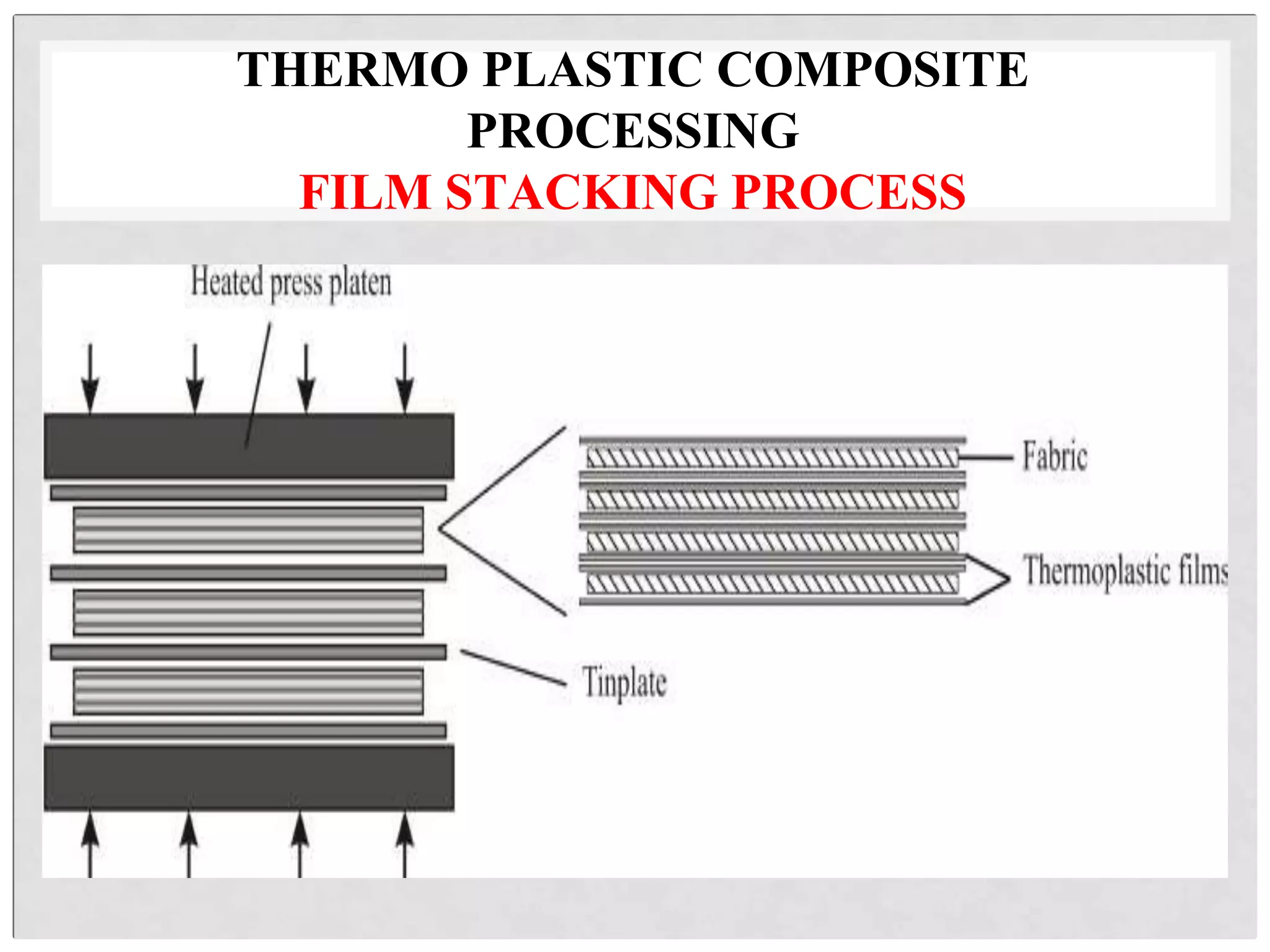

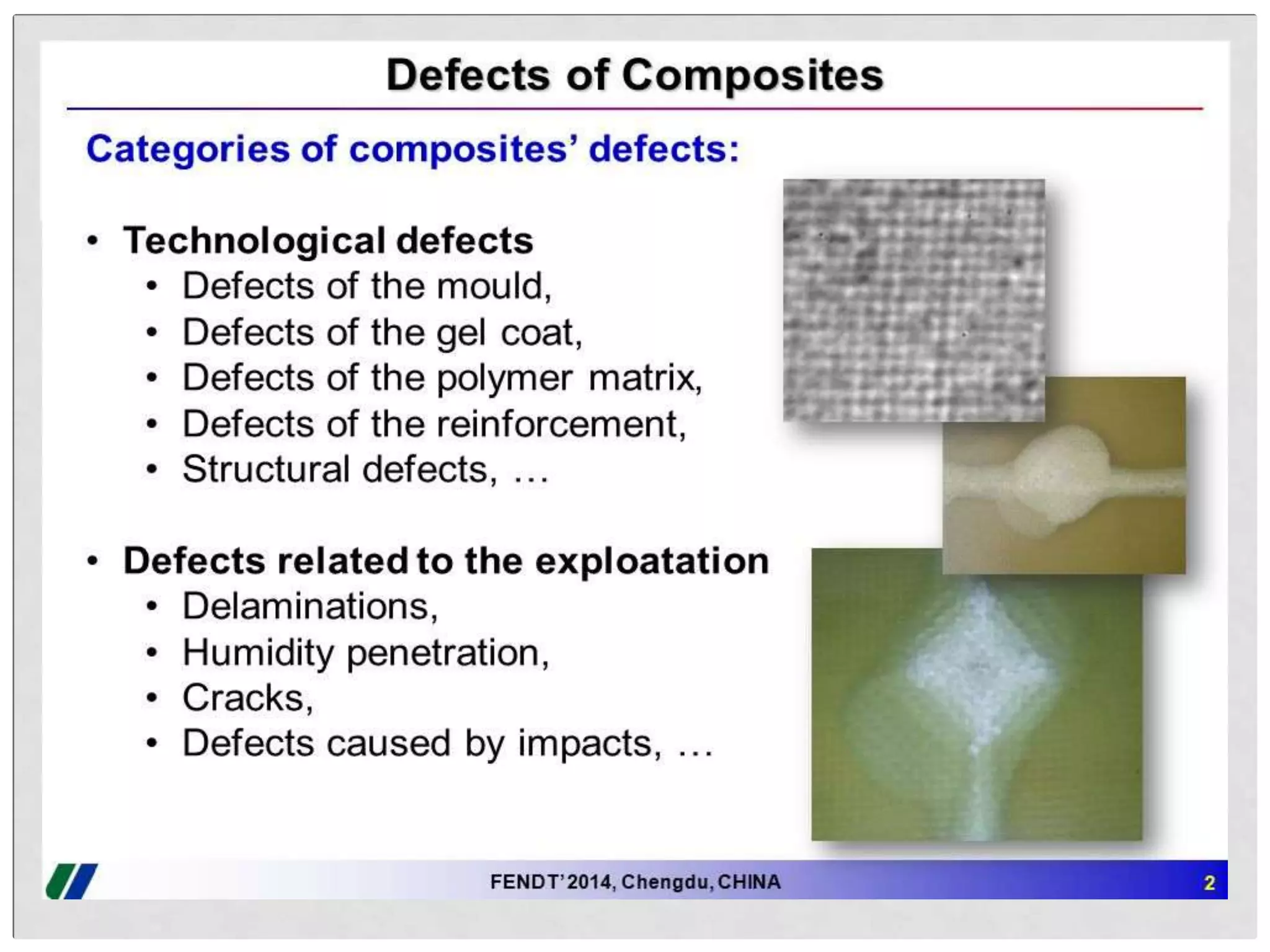

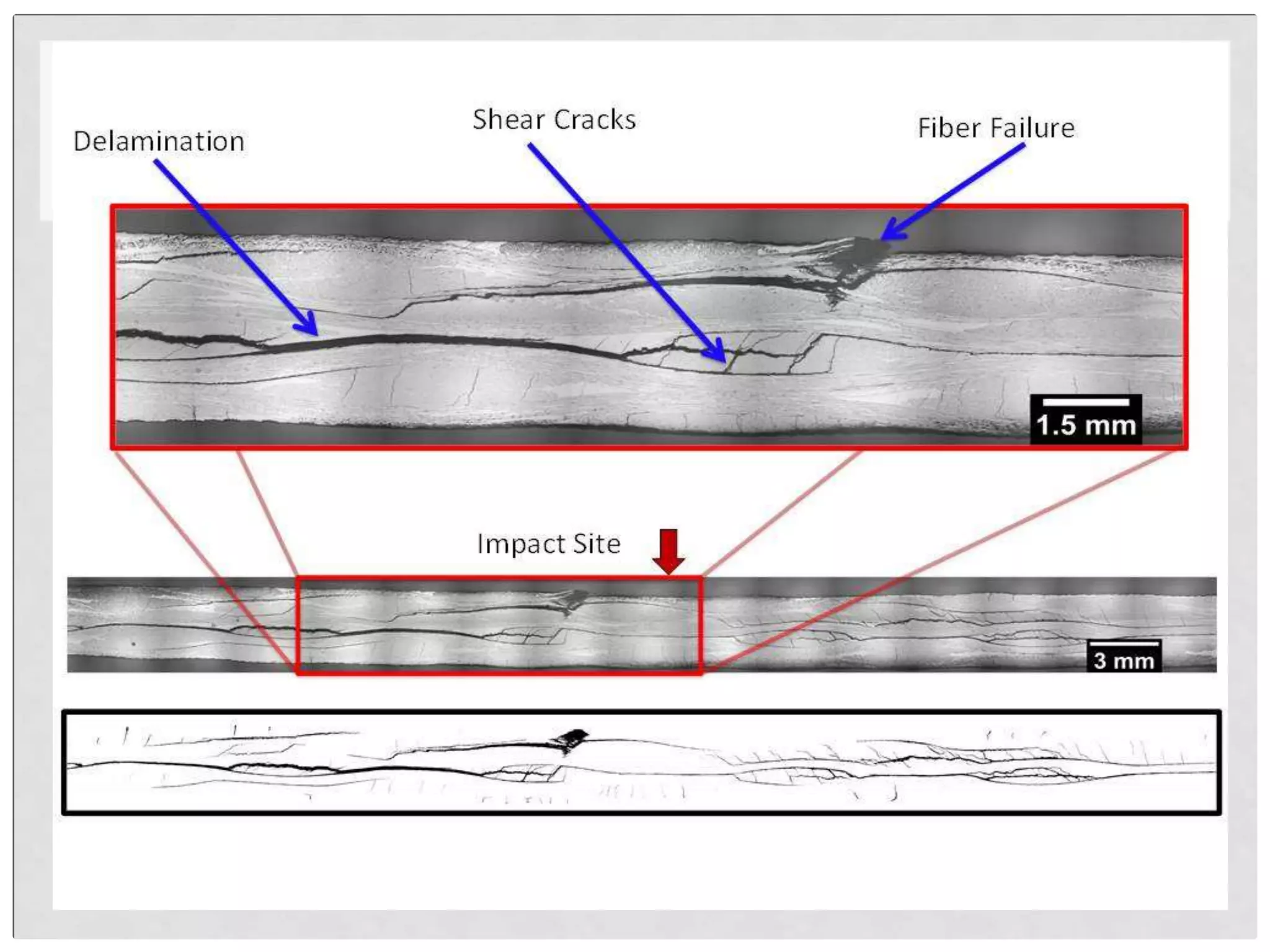

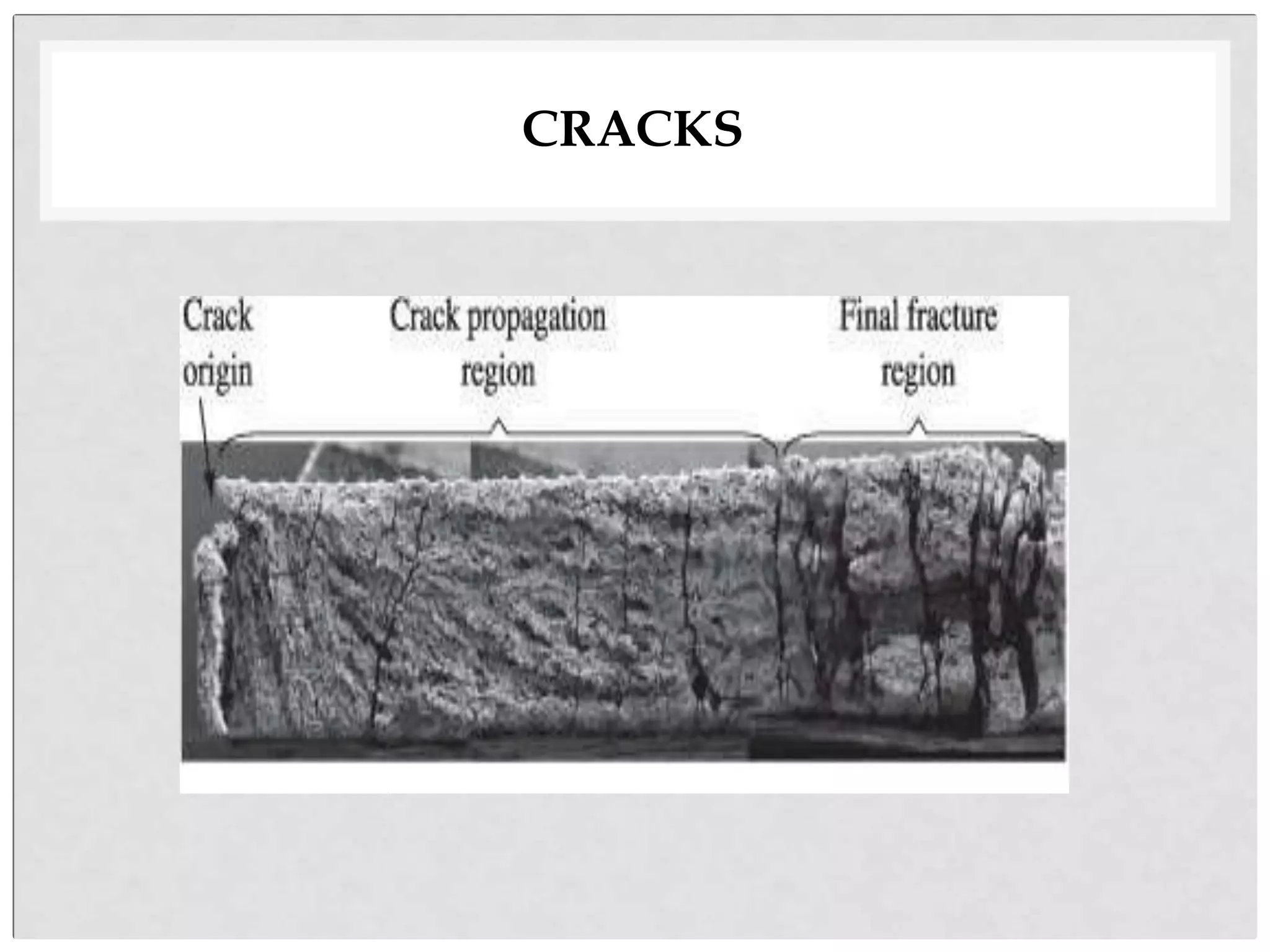

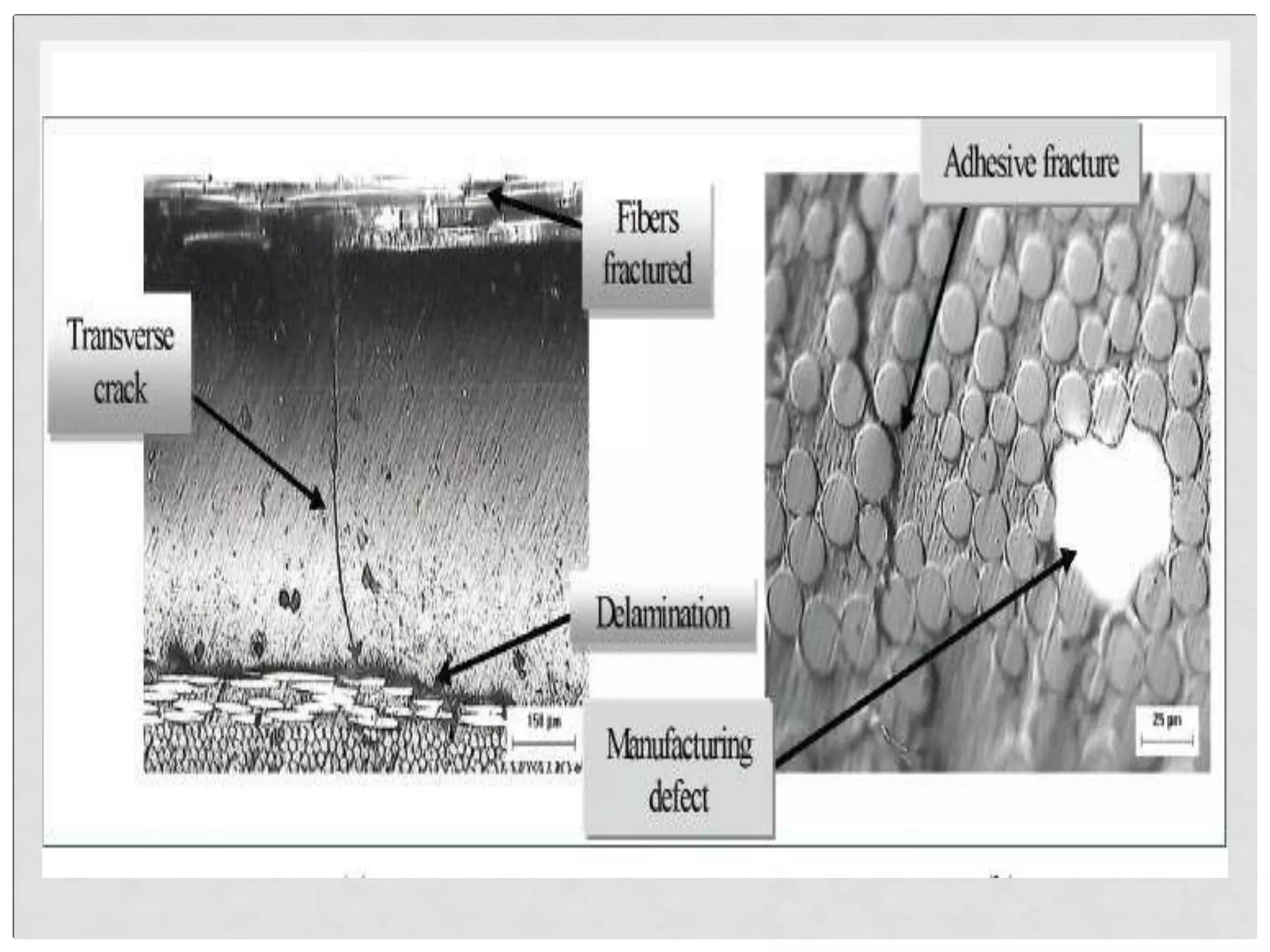

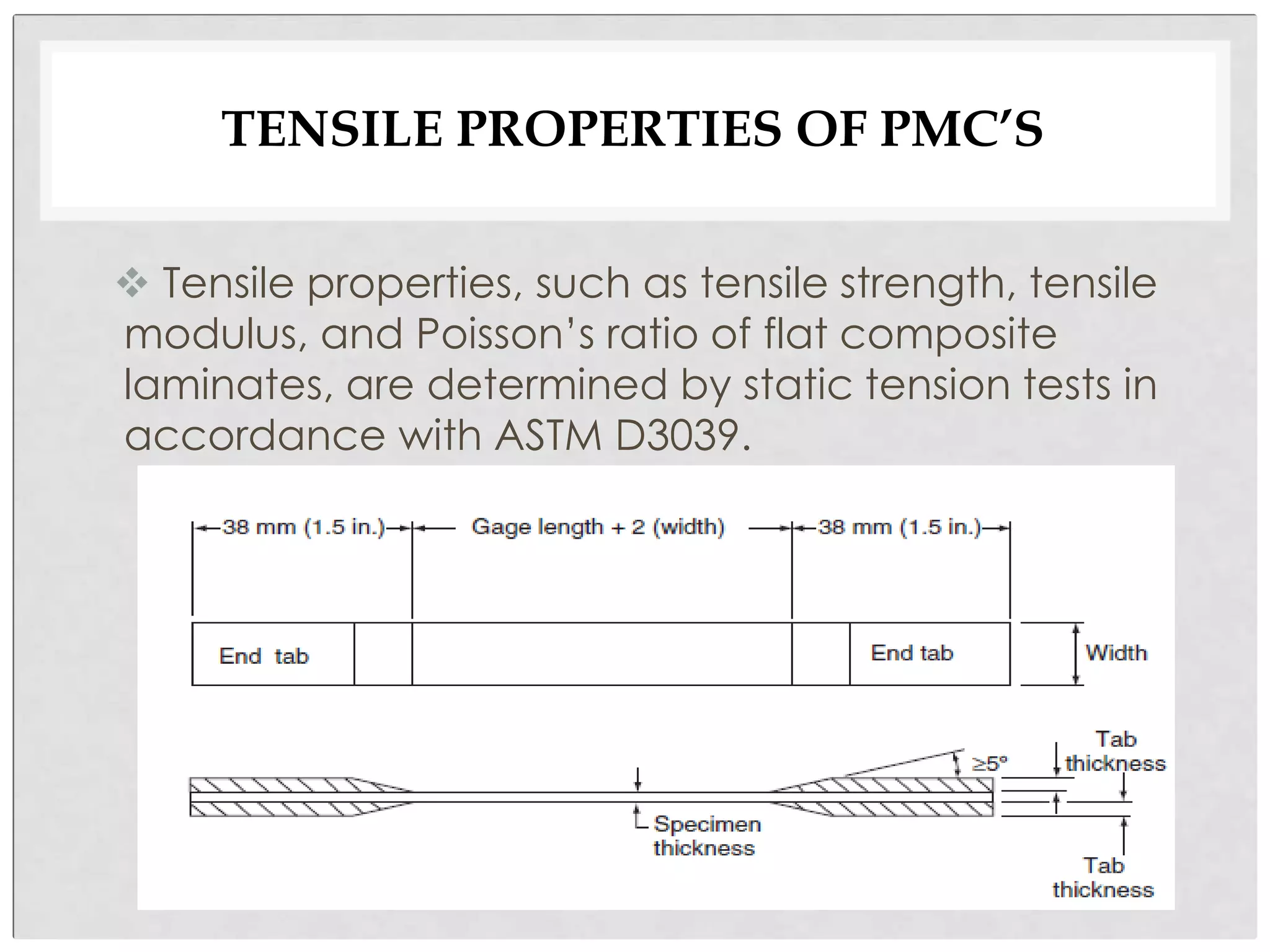

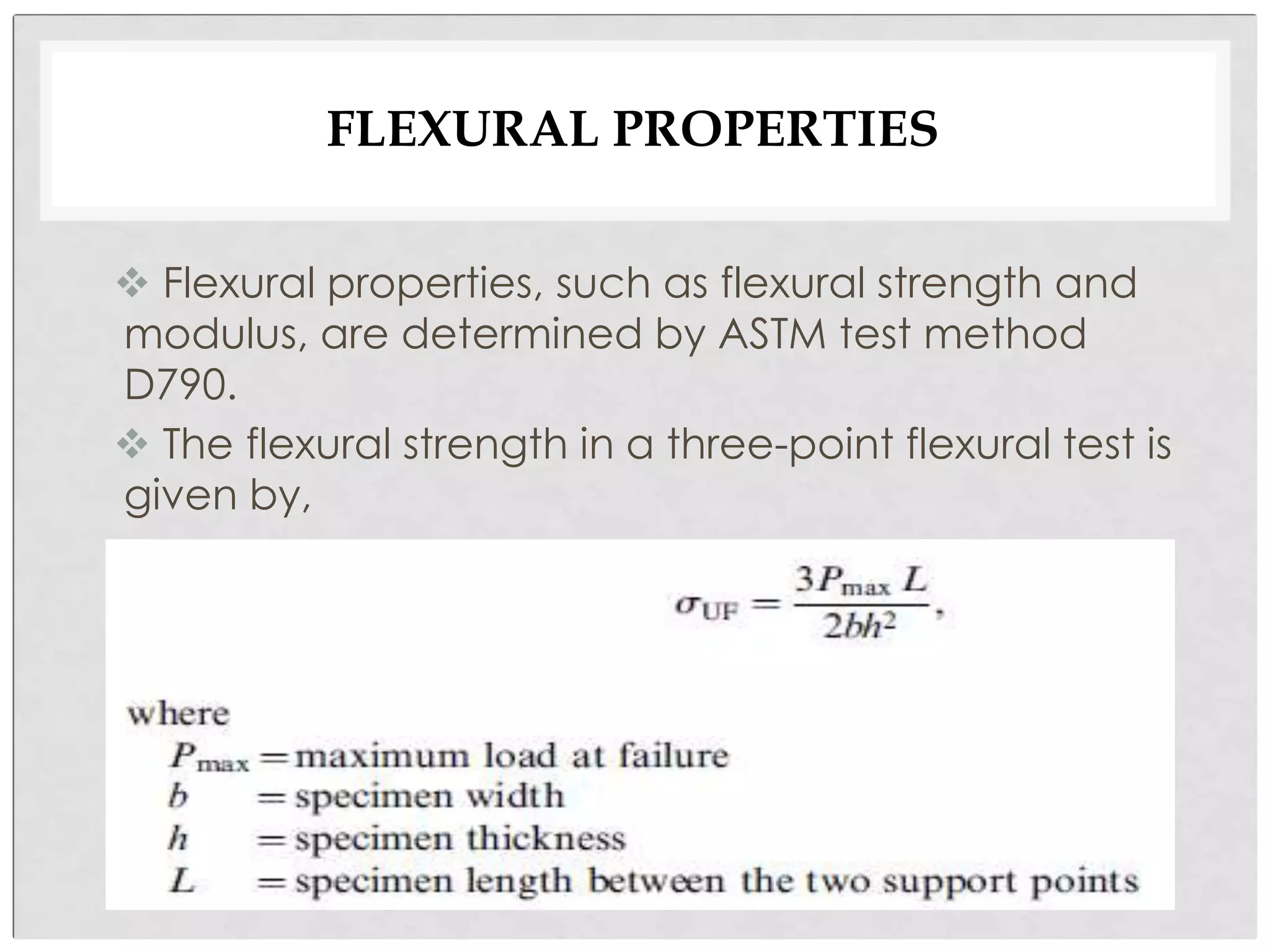

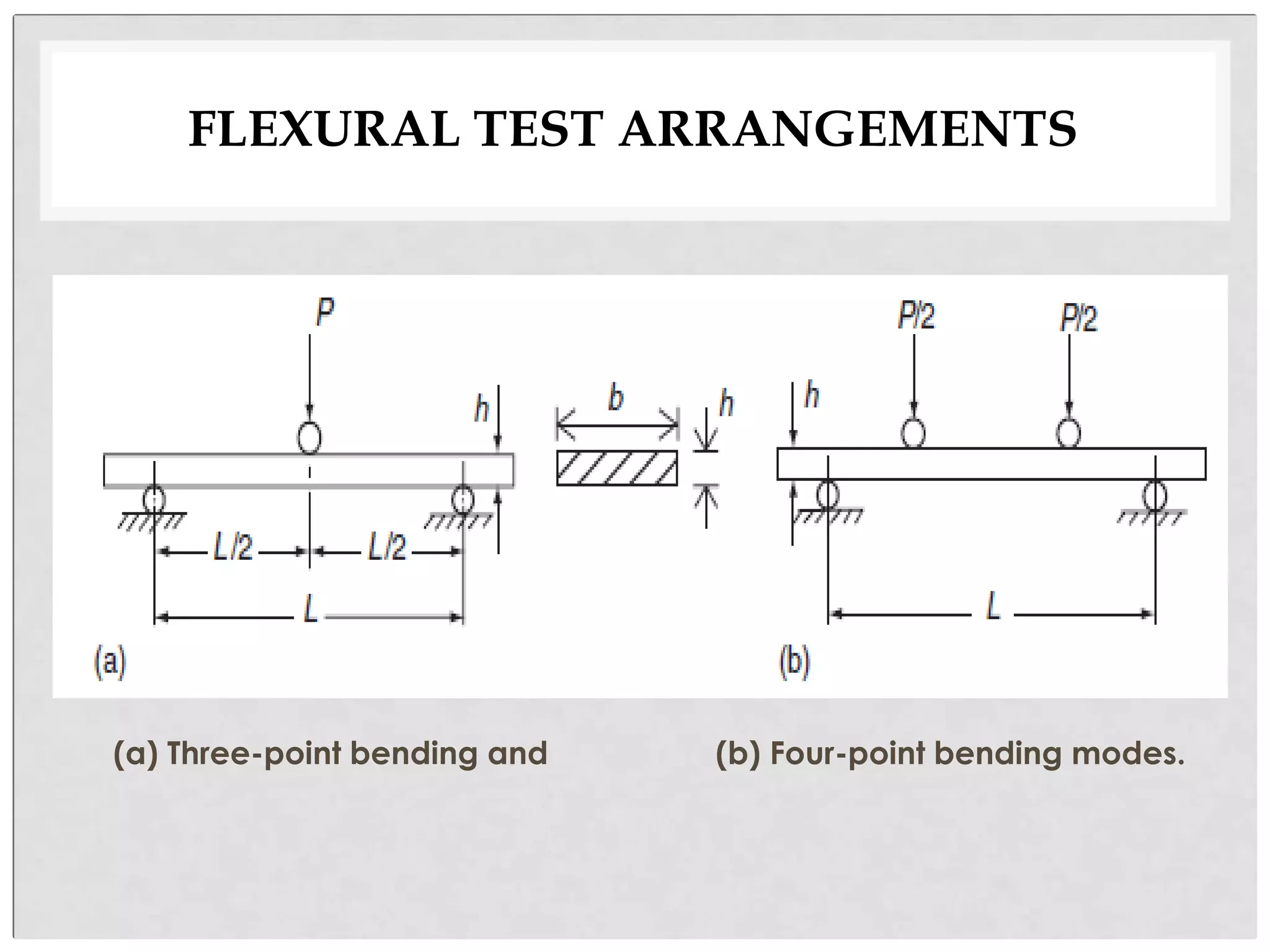

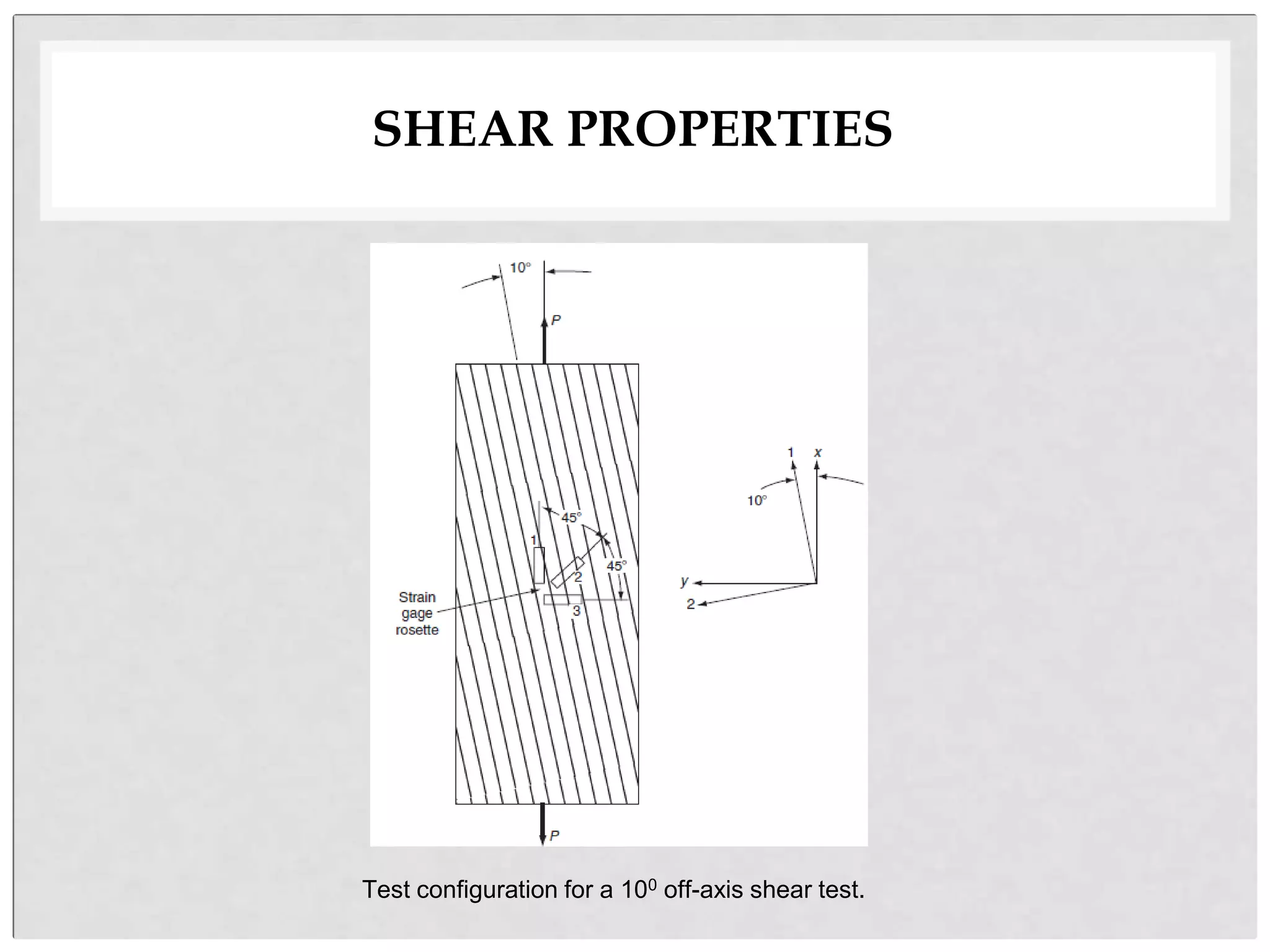

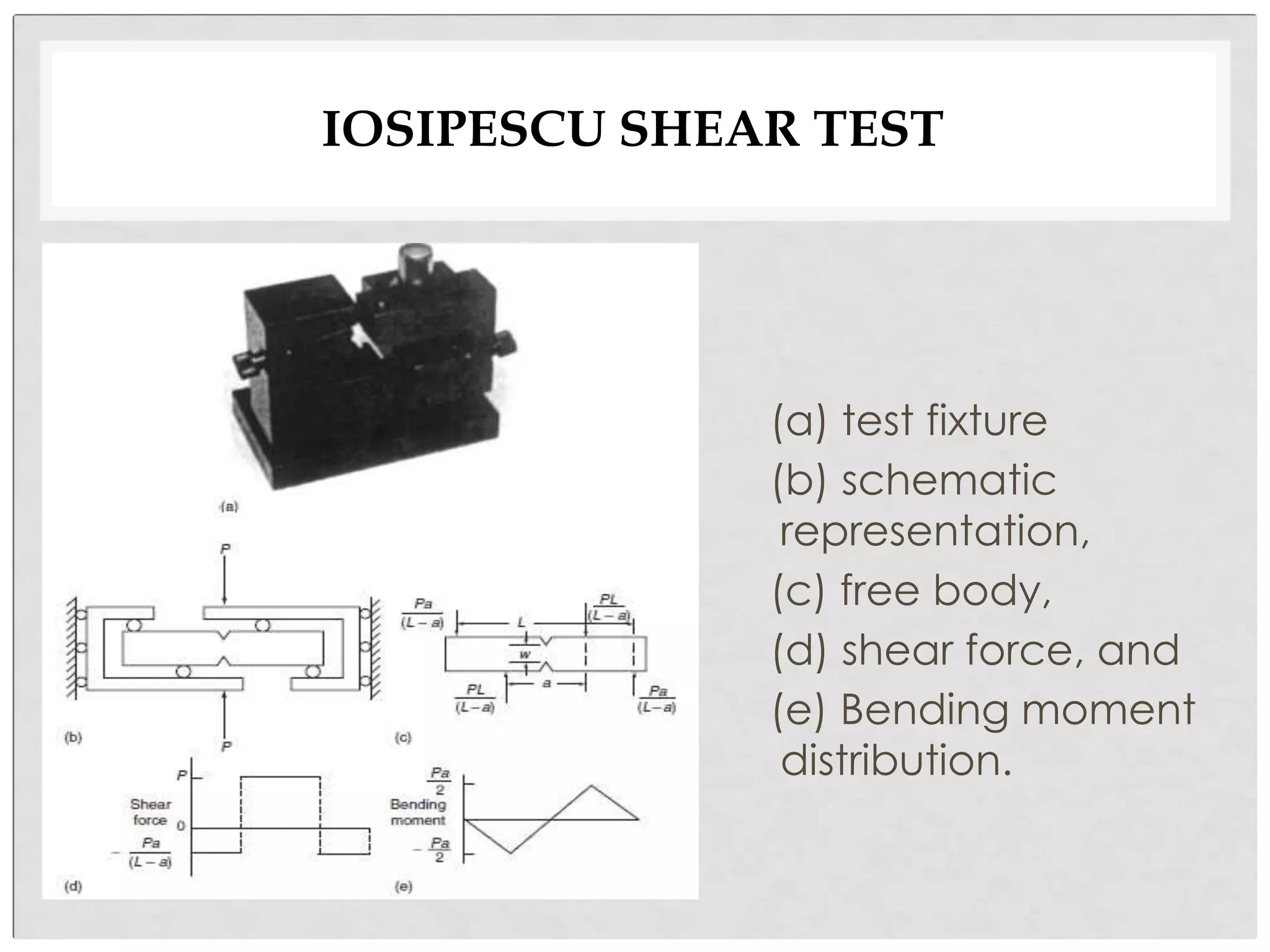

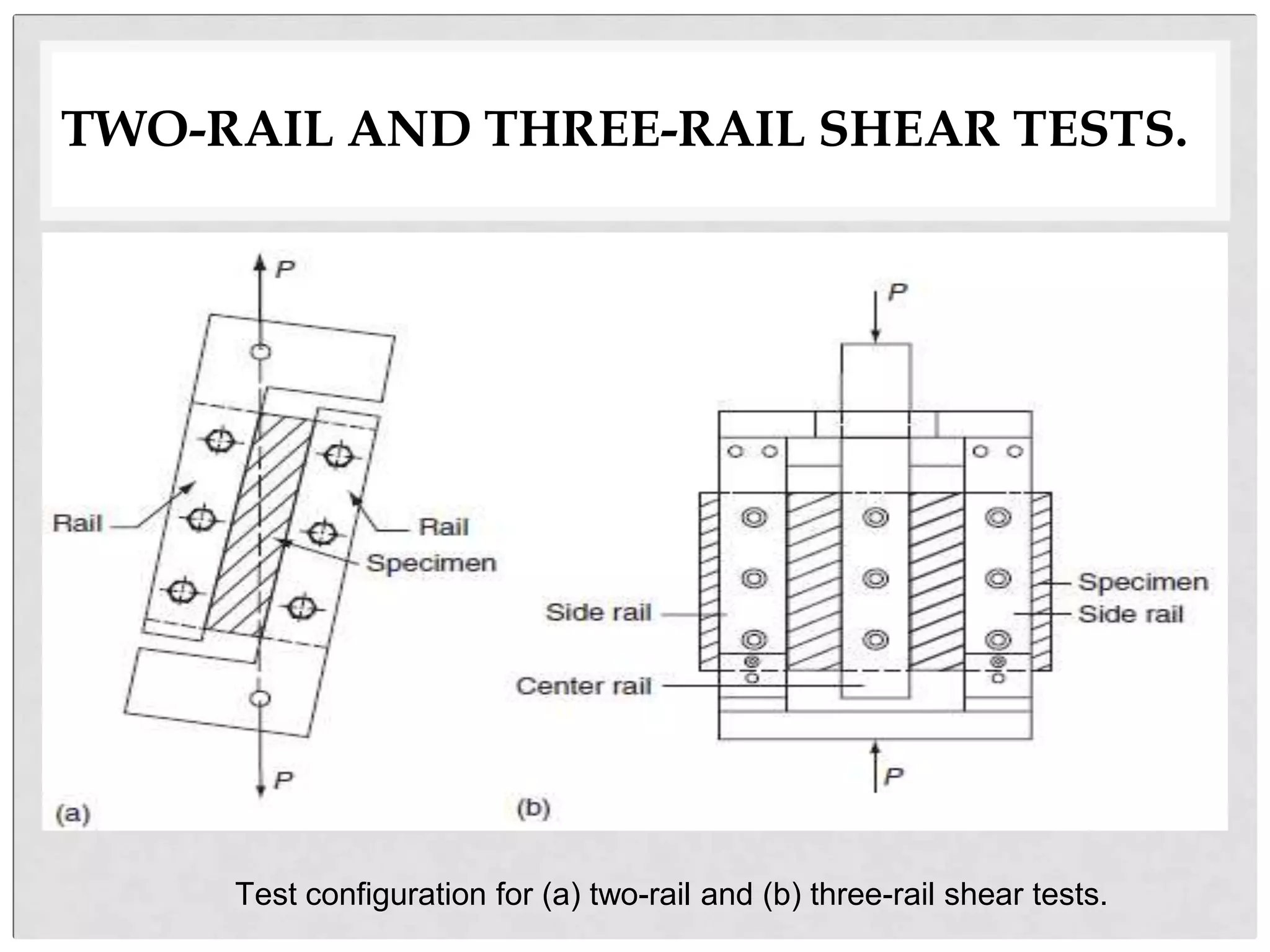

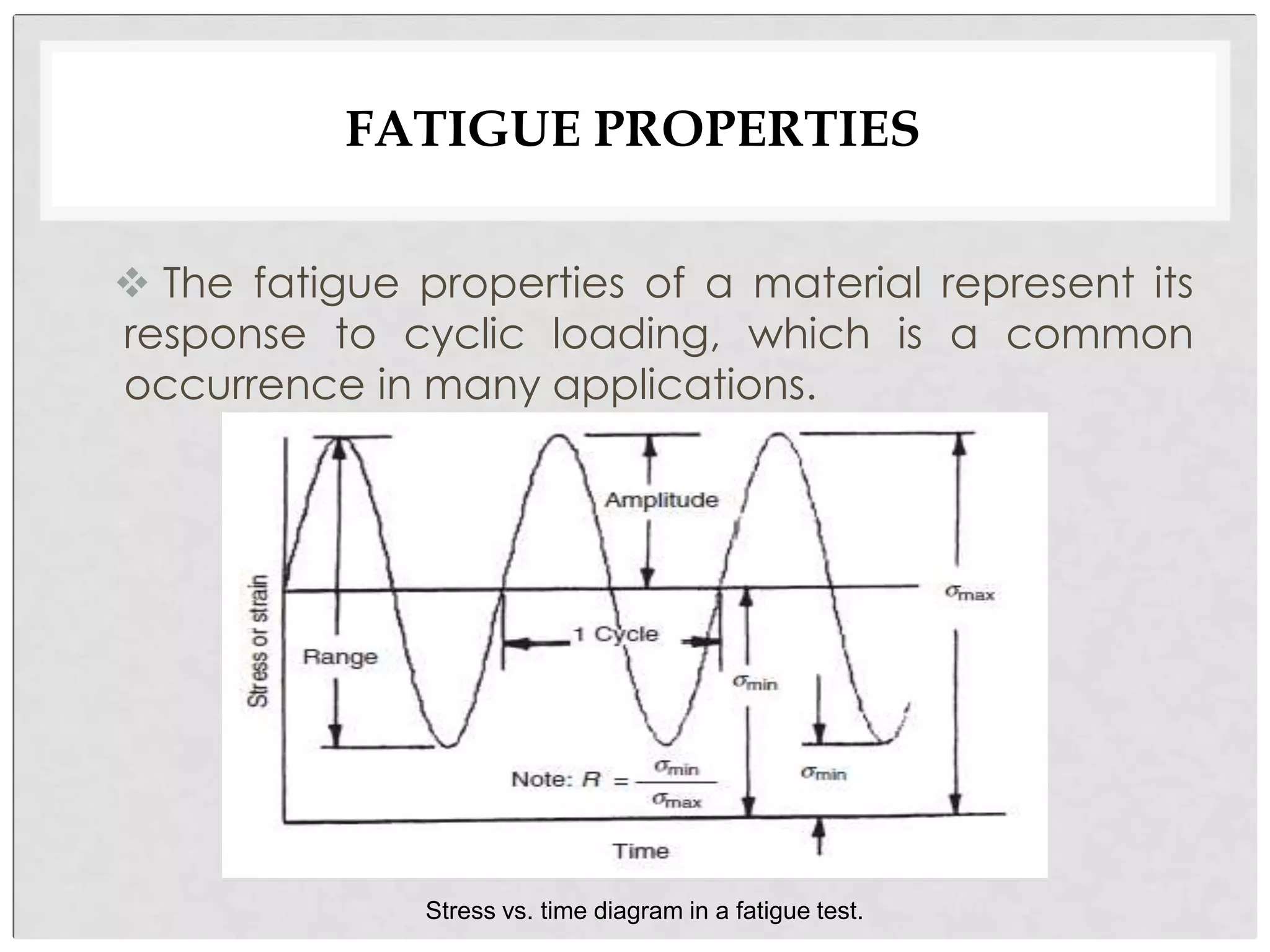

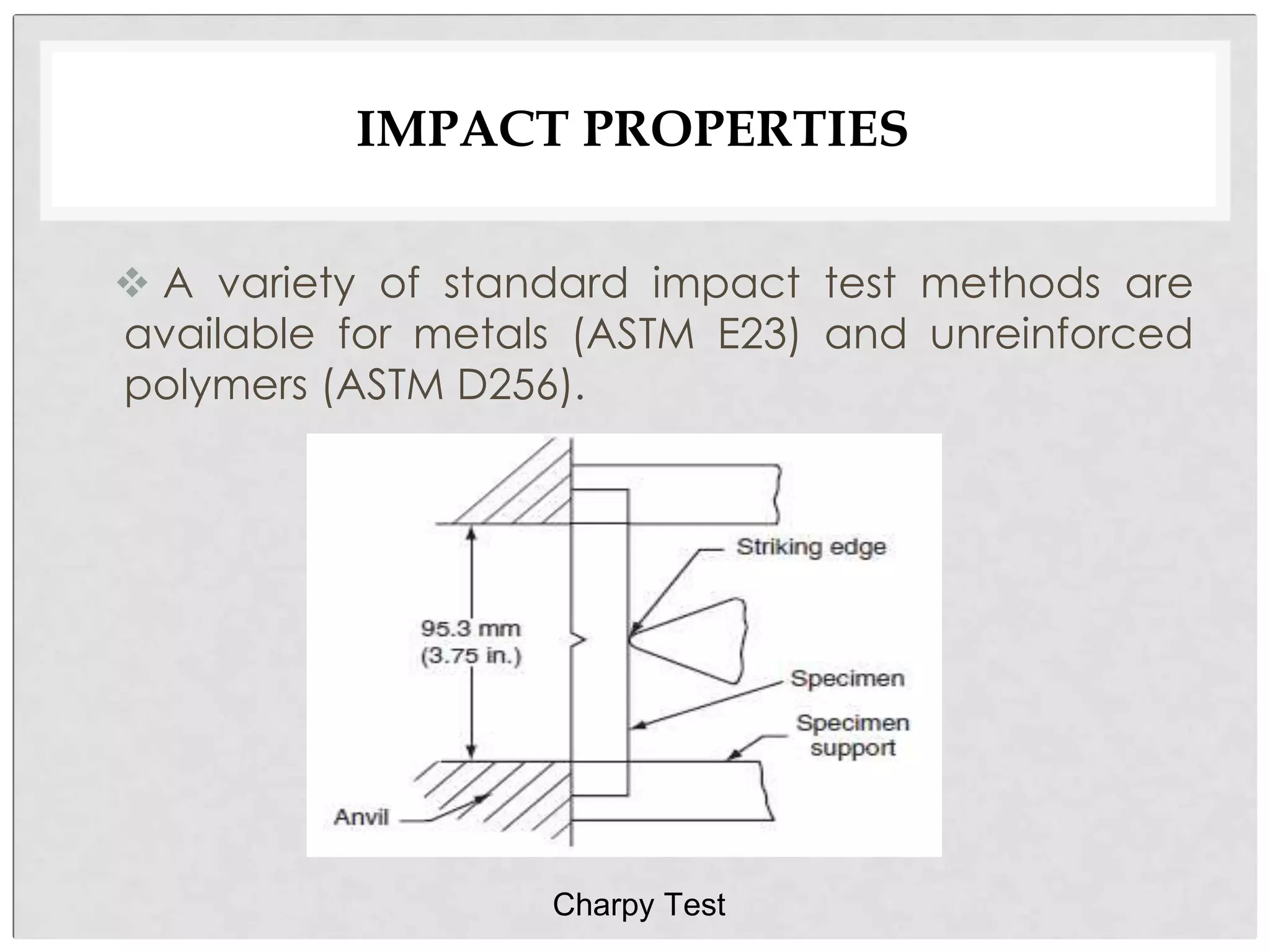

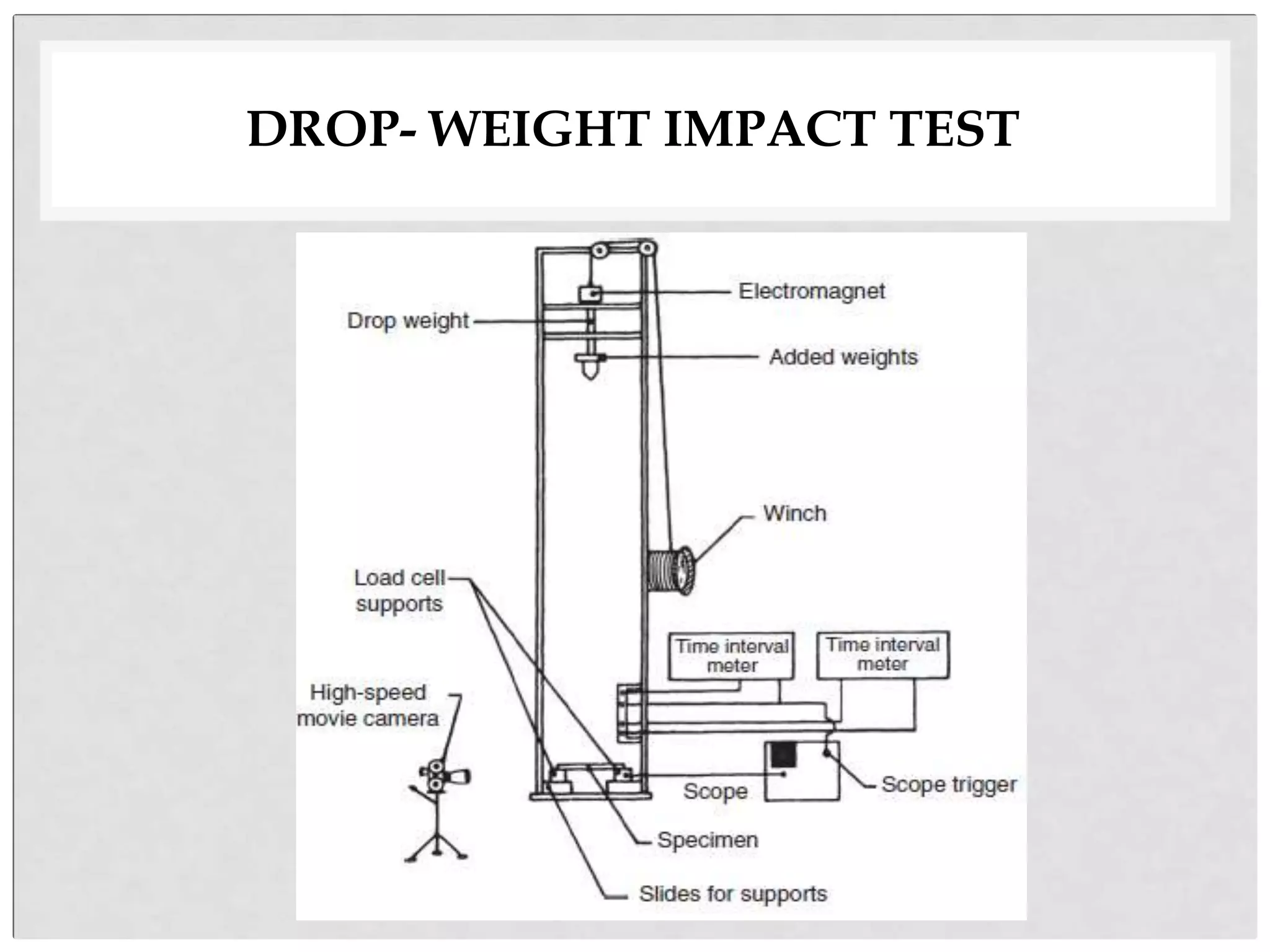

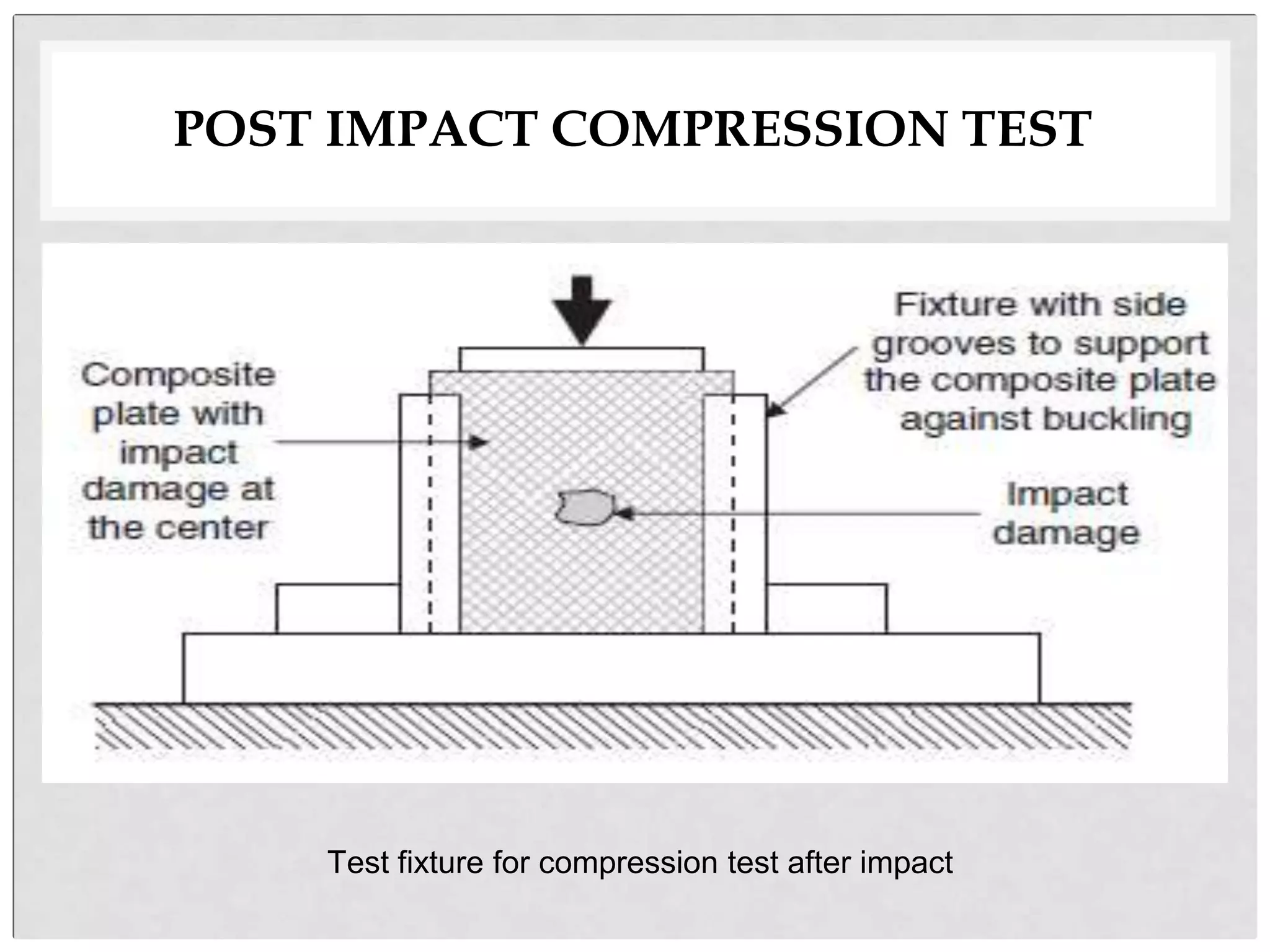

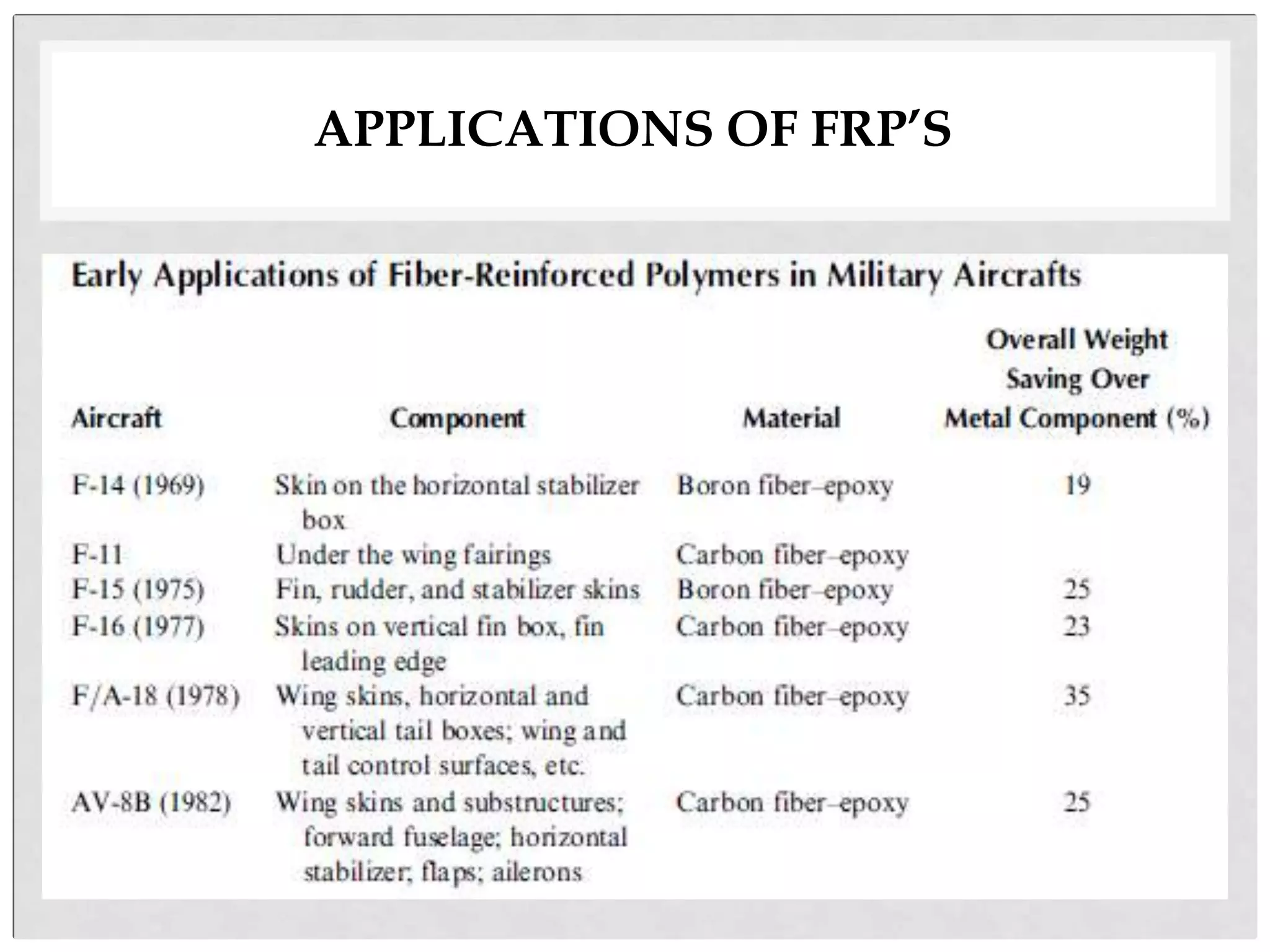

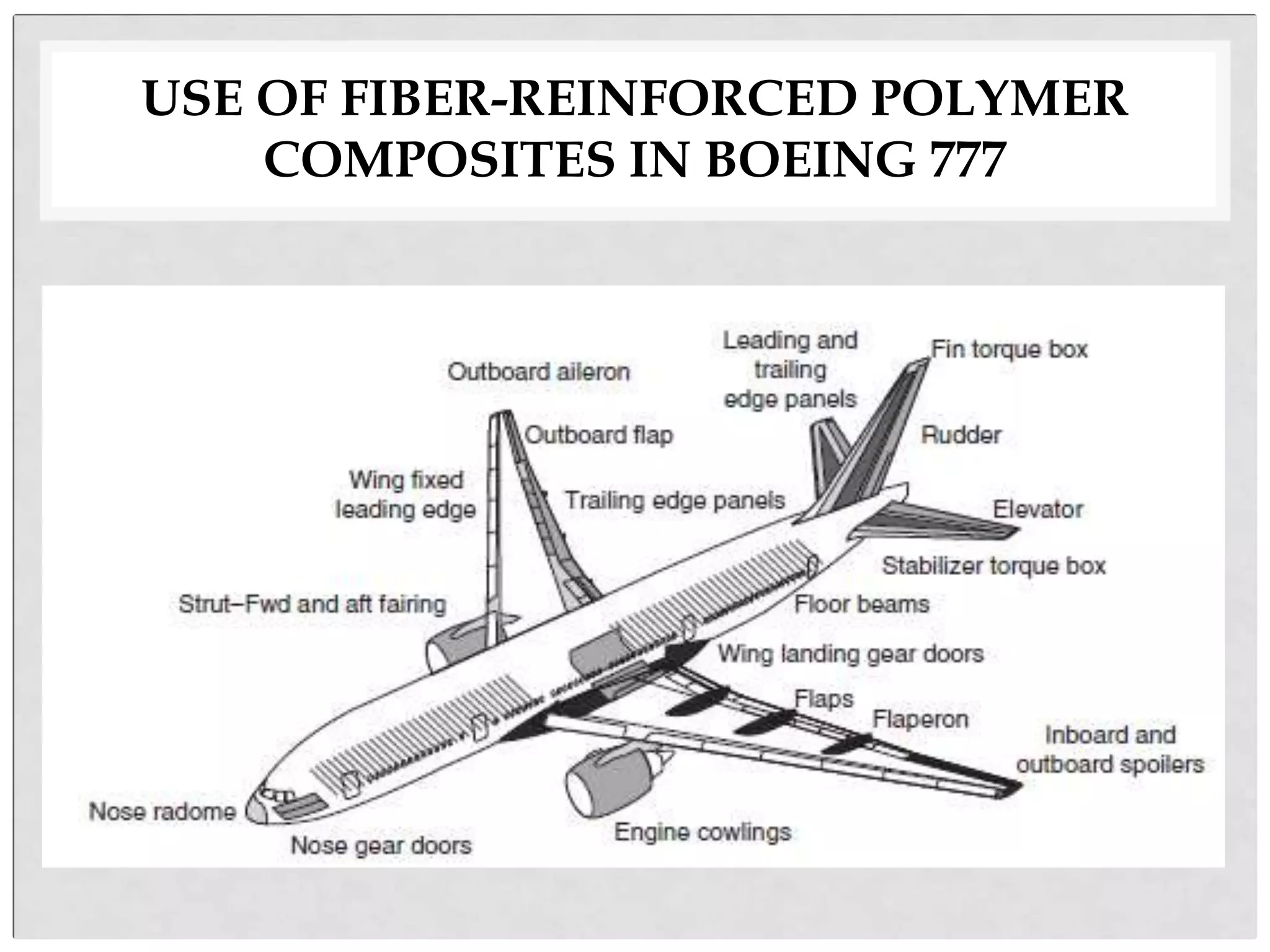

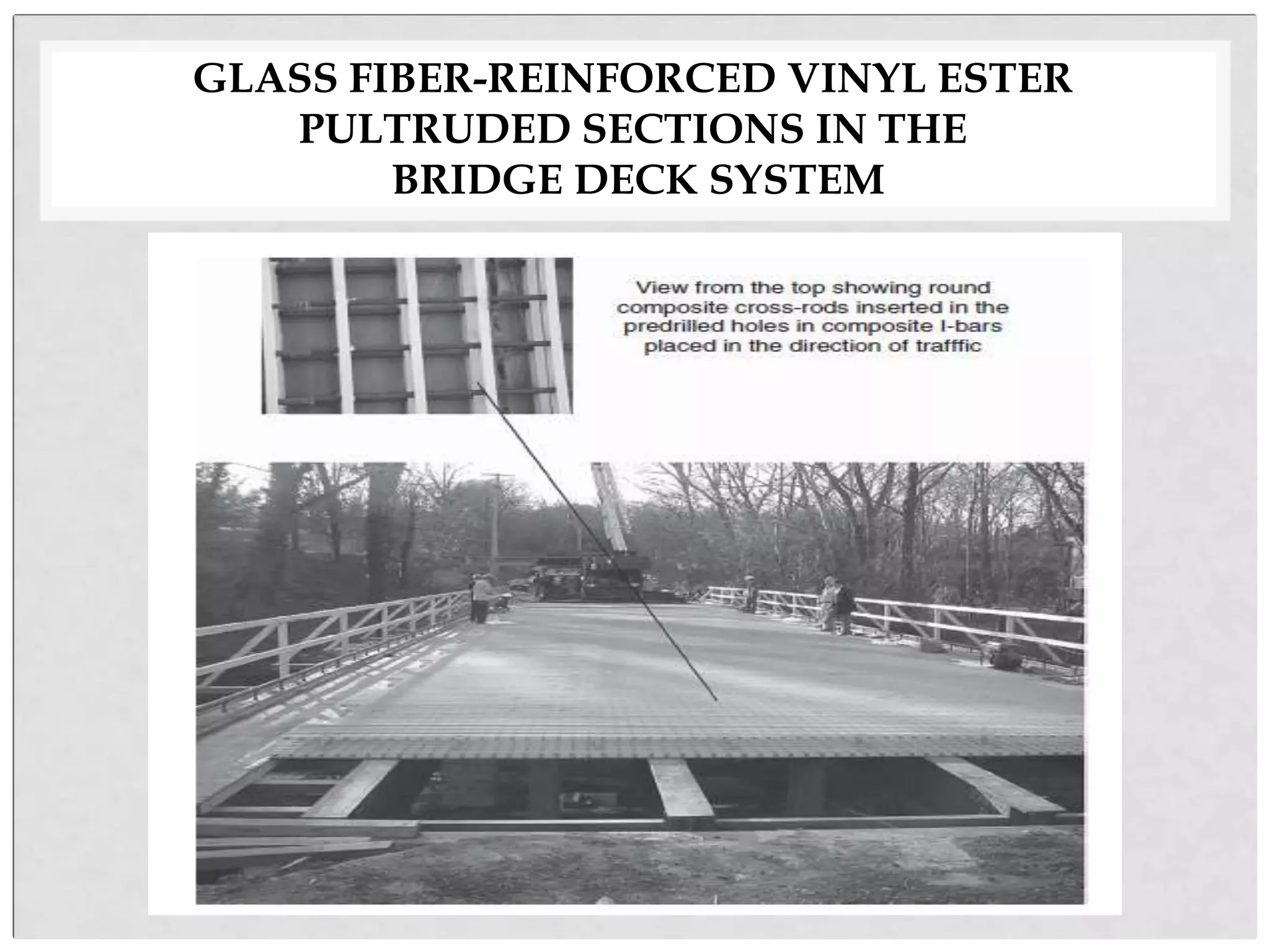

This document provides an overview of fiber reinforced composites (FRC). It begins with an introduction to FRCs, which are composite materials made of a polymer matrix reinforced with fibers, most commonly glass, carbon, or aramid fibers. The document then covers the classification of FRCs based on matrix type, fiber types, manufacturing processes like hand layup and filament winding, curing processes, potential defects, and mechanical properties testing including tensile, flexural, shear, fatigue, and impact properties. Finally, applications of FRCs are discussed such as use in the aerospace, automotive, marine, and construction industries.