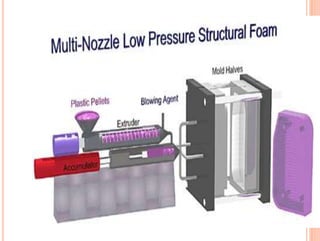

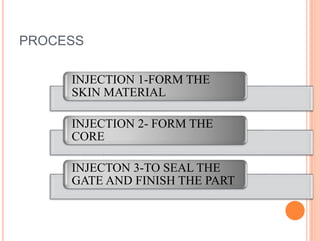

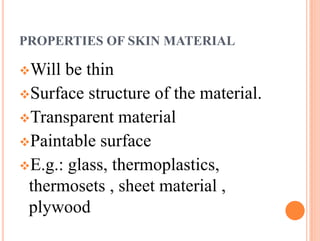

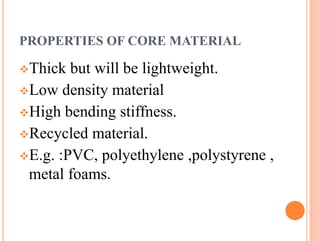

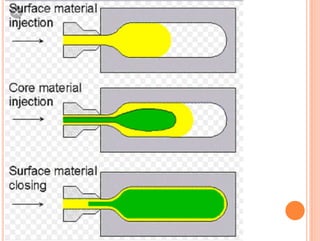

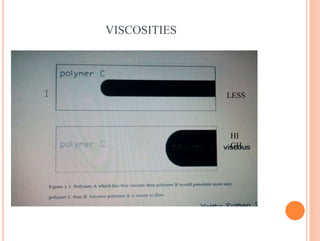

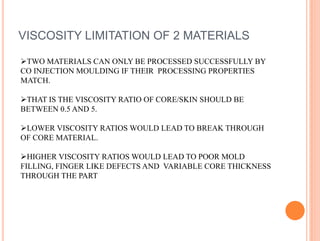

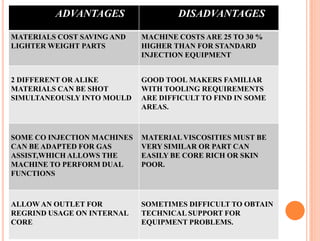

This document discusses different molding processes including structural foam molding, sandwich molding, and their advantages and disadvantages. Structural foam molding is a low pressure injection molding process where gas is introduced into molten polymer to reduce density and weight. It requires less pressure than other molding processes. Sandwich molding involves injecting two or more polymers one after another through the same gate to form a layered part with different materials for the core and skin. This allows for weight reduction and various material combinations. Advantages of these processes include lower costs, weight reduction, design flexibility, and strength to weight ratios. Disadvantages include potential for air bubbles or shrinkage.