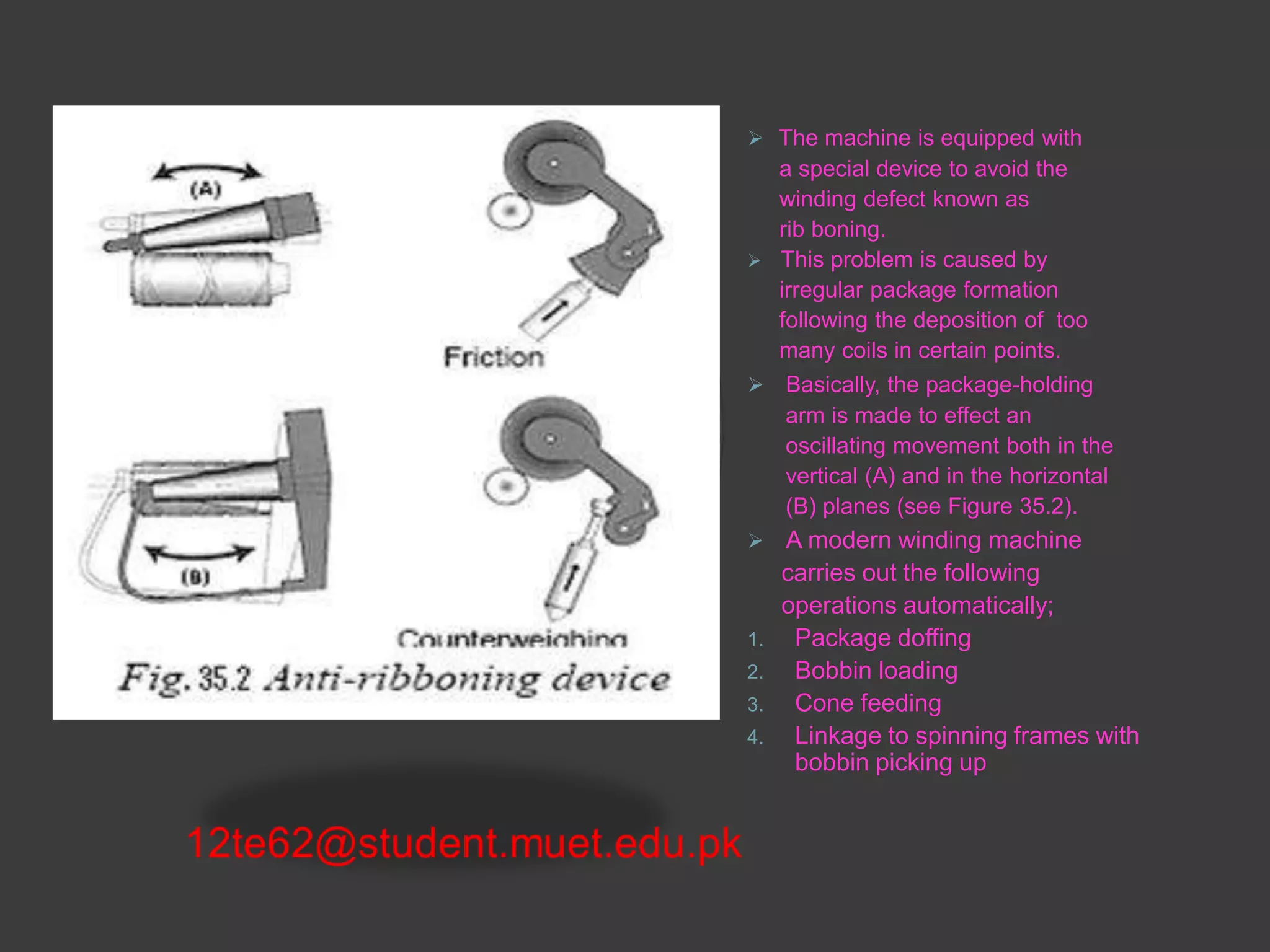

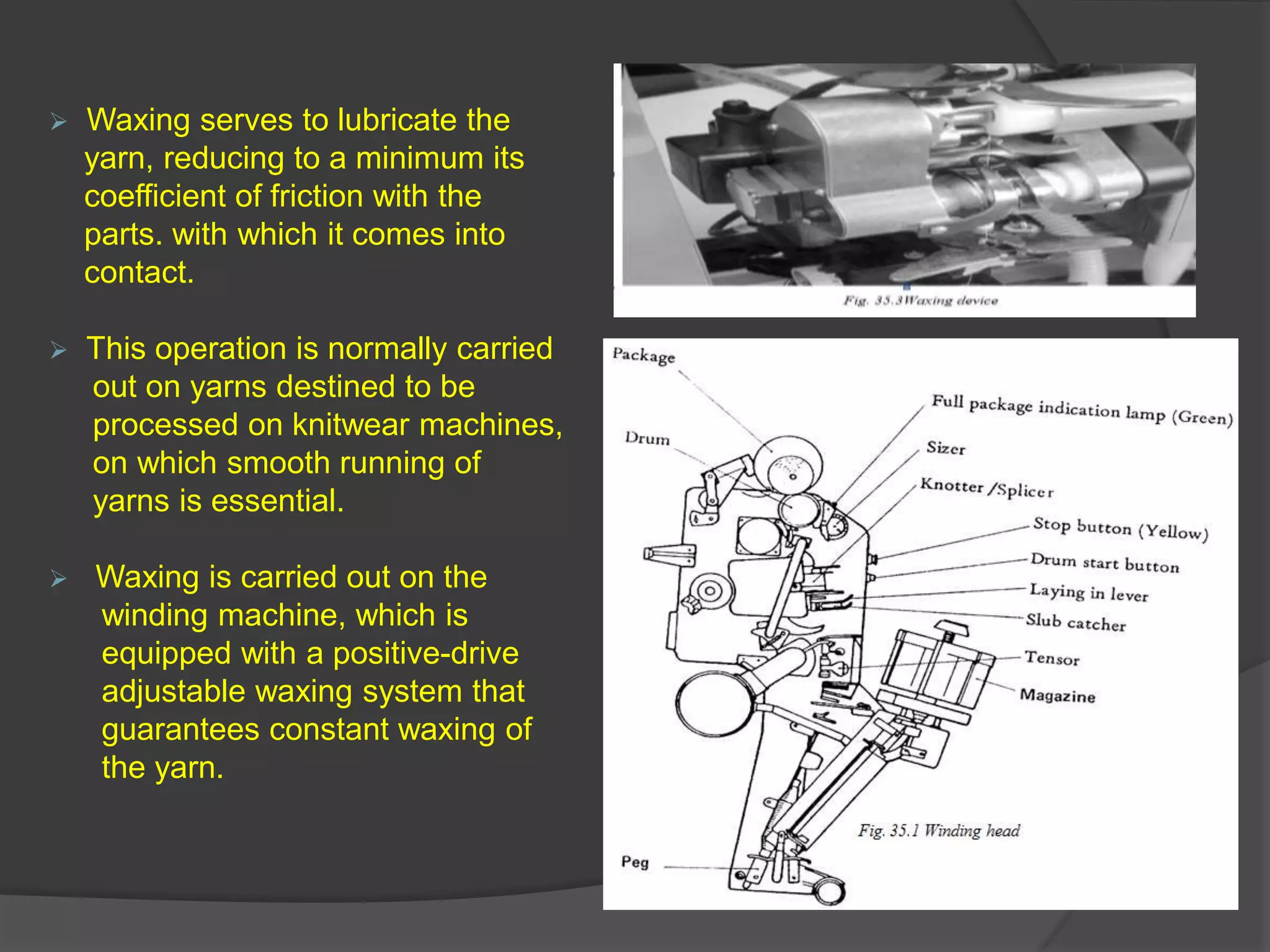

The document discusses the process of auto cone winding. It begins by defining auto cone winding as a type of winding machine that converts ring bobbins into large cones, removing spinning faults. It describes the parts of the auto cone machine like the cradle, drum, magazine, and tension assembly. The working principle involves placing filled ring bobbins in the magazine, unwinding the yarn through tensioning and waxing units, splicing any broken yarns, and winding the yarn onto cones on the drum to form larger packages.