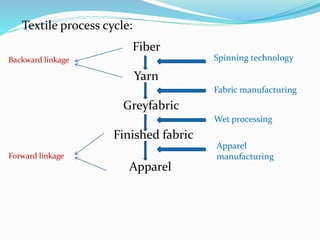

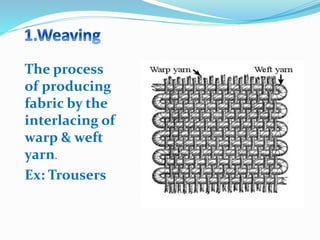

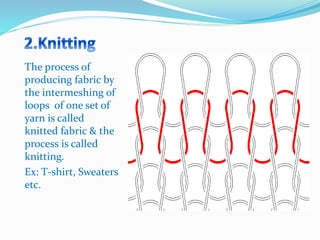

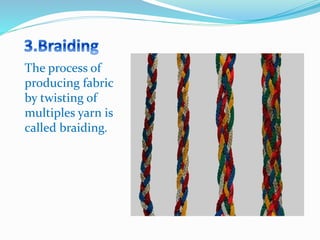

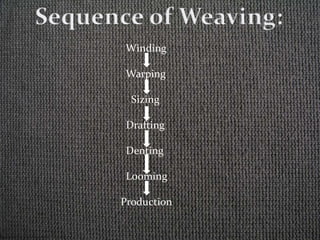

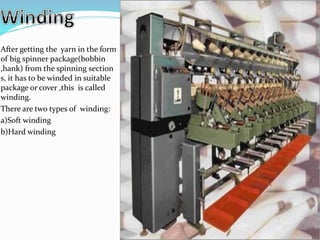

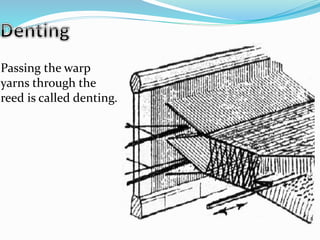

The document summarizes the textile process cycle from fiber to finished apparel. It describes the key stages as fiber, yarn production, grey fabric, finished fabric, and apparel manufacturing. It then provides more details on specific textile manufacturing processes like weaving, knitting, braiding, and non-woven production. Finally, it outlines some preparatory weaving processes like winding, warping, sizing, drafting, and denting.