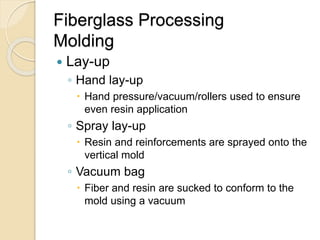

Fiberglass is a composite material made of glass fibers set in a resin matrix. It combines light weight with strength, providing a weather-resistant and robust material. There are four main methods to produce fiberglass: hand lay-up, spray lay-up, filament winding, and pultrusion. Fiberglass has applications in industries like telecommunications, construction, automotive, boats, and water/waste systems due to its properties of strength, corrosion resistance, and insulation.