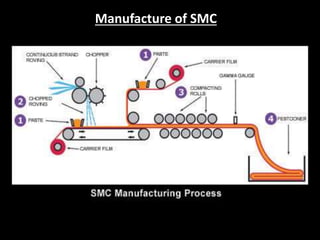

Sheet molding compound (SMC) is a composite material made of long glass fibers, minerals, and thermosetting resin formed into a malleable sheet. SMC contains 10-60% glass fiber reinforcement that is longer than in bulk molding compound, between 1/2-1 inch. To make SMC, a resin-coated film is layered with chopped fiber strands and pressed between rollers to embed the fibers. The layered sandwich cures while wound, then the film is removed and SMC is molded. SMC offers high strength, corrosion resistance, and electrical insulation for uses like electrical parts housings and medical and dental equipment.