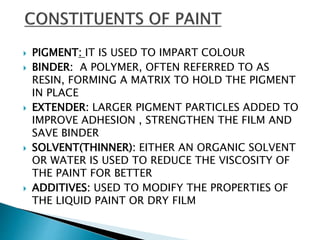

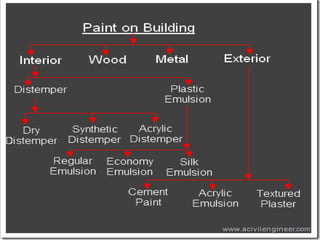

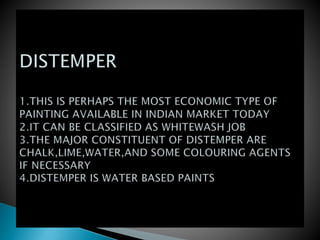

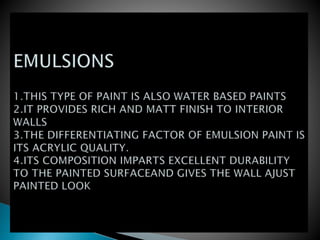

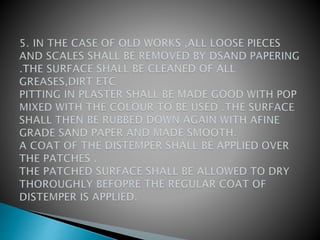

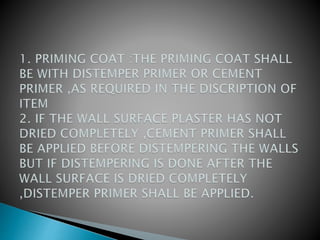

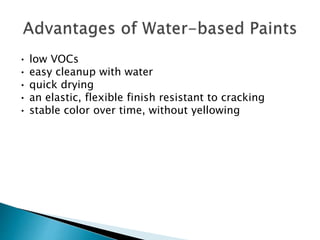

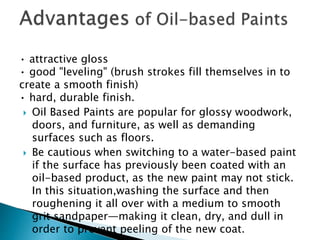

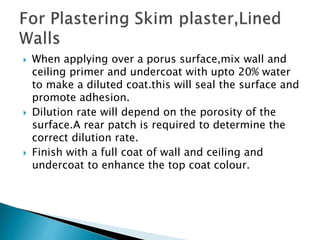

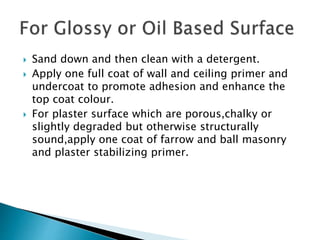

The document provides a detailed overview of paint composition, including its components such as pigments, binders, extenders, and solvents. It discusses different types of paints, their applications, and characteristics like durability and drying times, while also outlining best practices for application and surface preparation. Additionally, it highlights the distinctions between water-based and oil-based paints, emphasizing the importance of choosing the right base coats for a long-lasting finish.