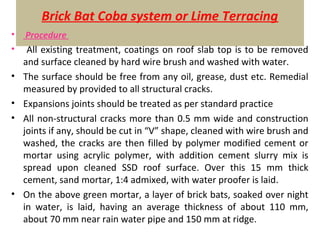

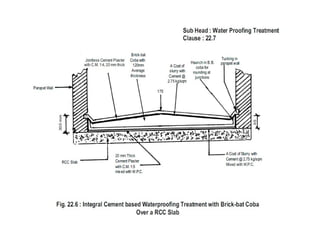

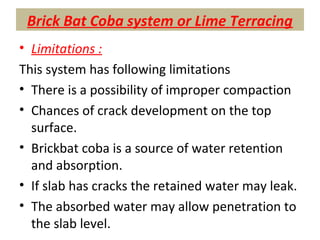

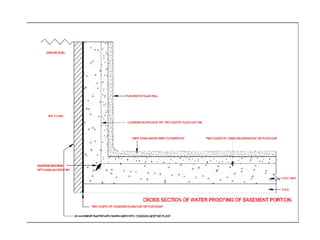

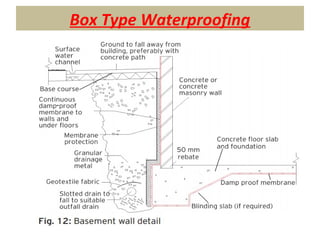

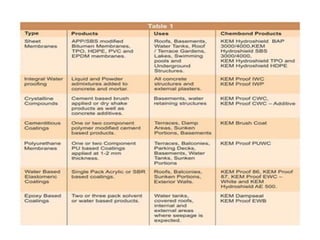

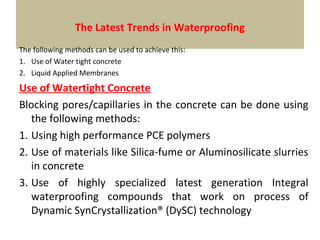

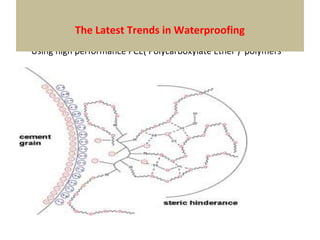

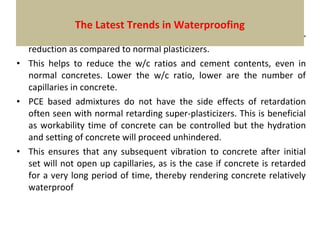

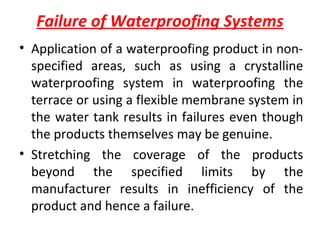

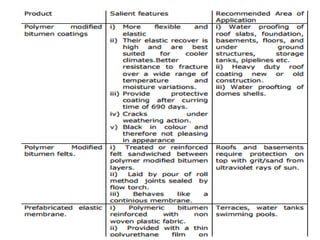

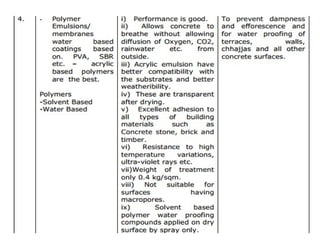

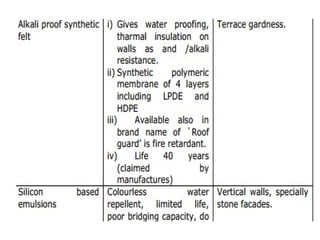

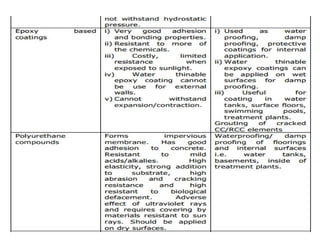

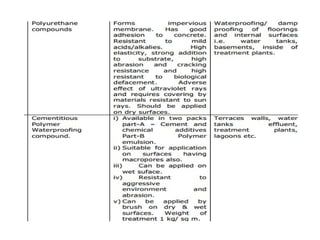

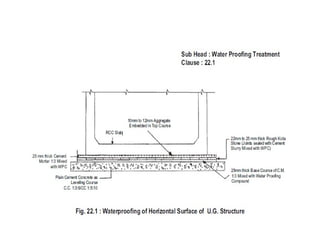

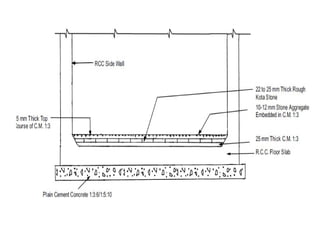

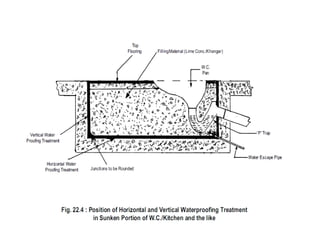

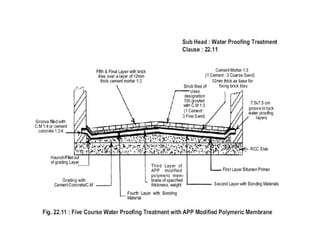

This document provides an overview of various waterproofing methods. It defines waterproofing and explains the importance. It then describes conventional methods like brick bat coba, bituminous treatments, and box-type waterproofing. It also covers modern techniques like crystalline waterproofing and flexible membrane waterproofing systems. For each method, it provides details on materials, application procedures, advantages, and limitations. The document serves as a comprehensive reference on traditional and contemporary waterproofing options.