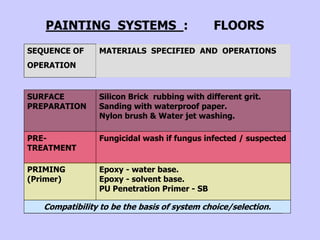

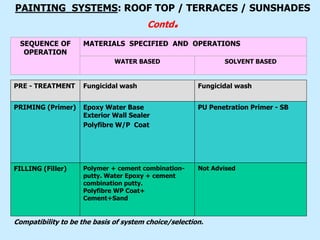

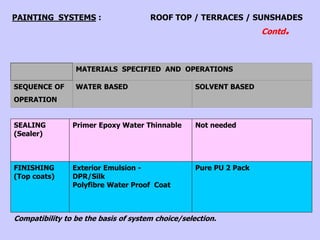

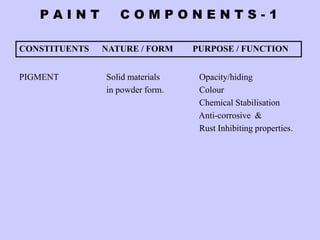

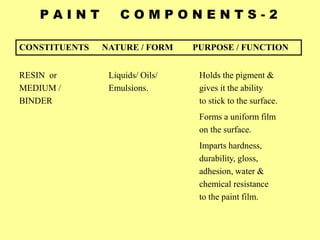

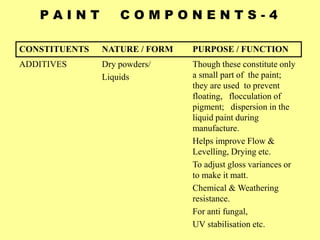

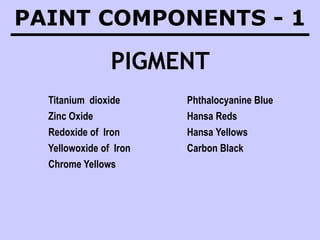

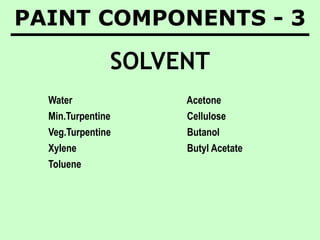

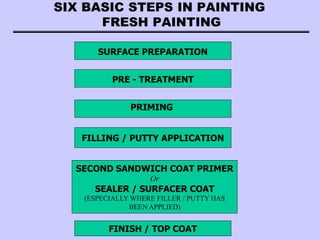

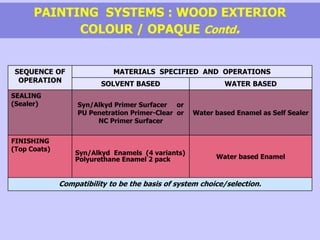

This document provides information about paint components, classifications, and painting procedures. It discusses the key constituents of paint including pigments, binders, solvents, and additives. It classifies paints according to their application such as architectural, automotive, industrial, and marine coatings. Finally, it outlines the six basic steps in painting which are surface preparation, pre-treatment, priming, filling, applying a sealer coat, and finishing coat.

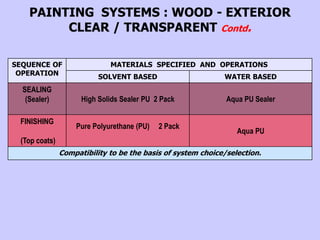

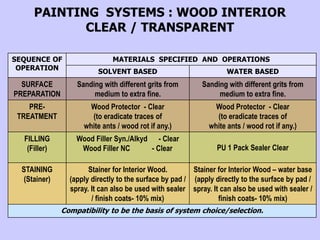

![SEQUENCE OF

OPERATION

MATERIALS SPECIFIED AND OPERATIONS

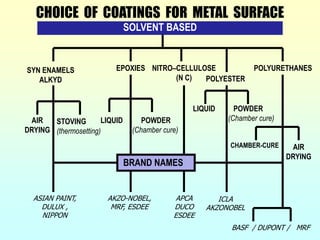

SOLVENT BASED WATER BASED

SURFACE

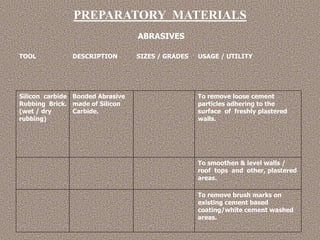

PREPARATION

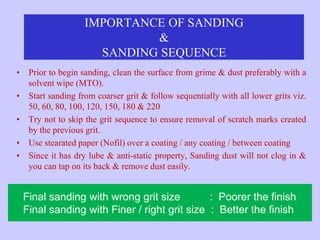

Sanding with different grits from

medium to extra fine.

Sanding with different grits from

medium to extra fine.

PRE-

TREATMENT

Wood Protector - Clear

(to eradicate traces of

white ants / wood rot if any.)

Wood Protector - Clear

(to eradicate traces of

white ants / wood rot if any.)

FILLING

(Filler)

Epoxy Putty

[only on holes/dents]

Aqua PU Sealer

STAINING

(Stainer)

Base coat Stain for Exterior Wood.

(apply directly to the surface

by brush/ spray)

Water based stain - exterior grade

(apply directly to the surface

by brush/ pad / spray)

Compatibility to be the basis of system choice/selection.

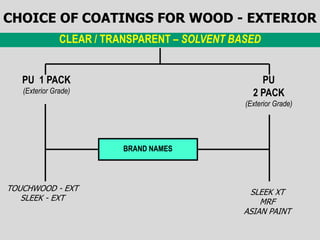

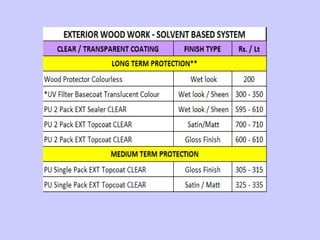

PAINTING SYSTEMS : WOOD - EXTERIOR

CLEAR / TRANSPARENT](https://image.slidesharecdn.com/01paint-classttc-iia-230102083608-21c9be74/85/01-Paint-Class-TTC-IIA-pptx-71-320.jpg)