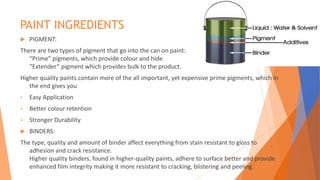

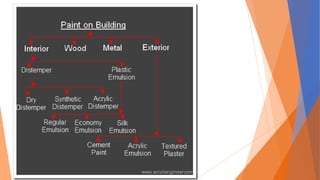

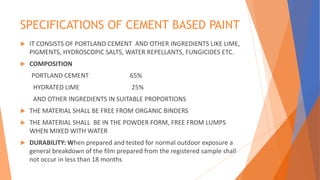

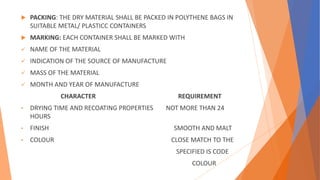

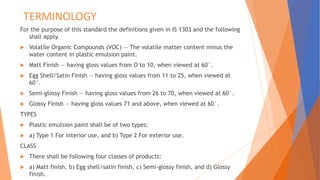

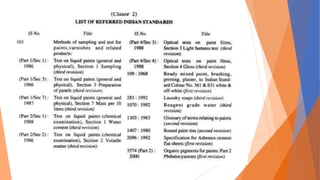

The document discusses different types of paints used for interior and exterior surfaces. It describes the key ingredients in paint like pigments, binders, liquids, and additives. It also outlines different types of surface finishes like white wash, color wash, distemper, cement paint etc. The preparation of surfaces prior to painting and application methods for different paint types are explained. Water based and oil based paints are compared in terms of their advantages.