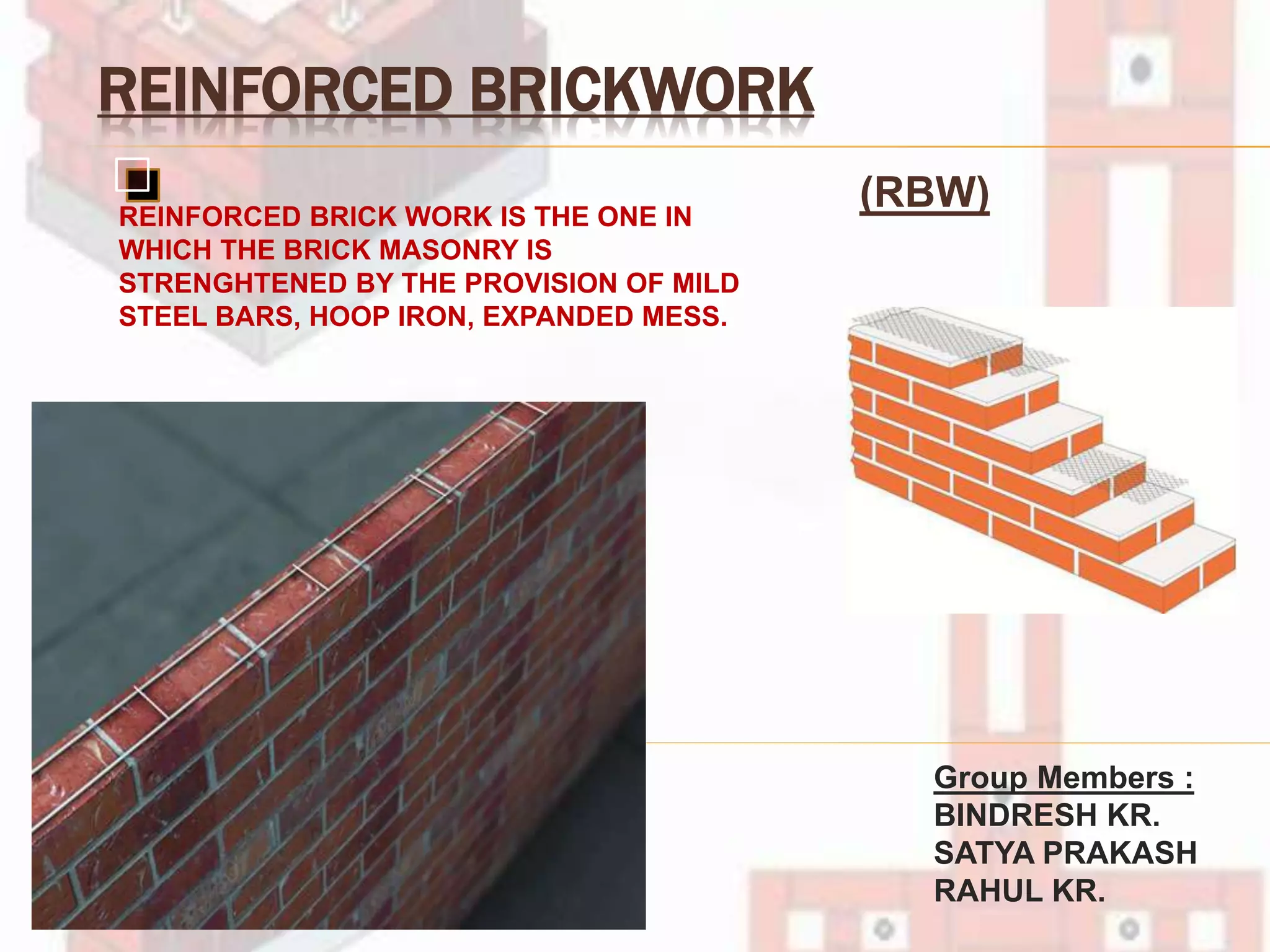

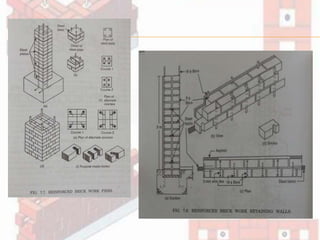

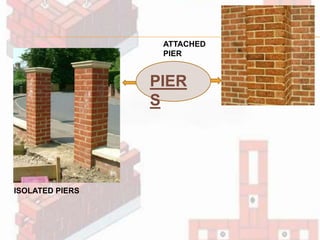

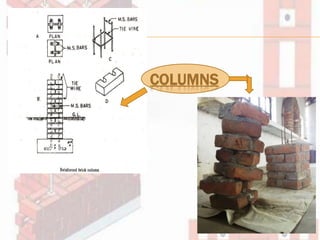

Reinforced brickwork (RBW) combines brick masonry with steel reinforcement to enhance its tensile strength and resistance to tensile and shear stresses, making it a strong structural material. The use of RBW has historical roots dating back to 1813, with applications in various constructions such as beams, columns, and retaining walls, often favored for its cost-effectiveness and low labor requirements compared to reinforced concrete. Proper curing methods and material selection, including high-density cement mortar, are essential to ensure the durability and performance of reinforced brickwork.