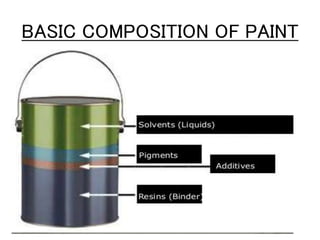

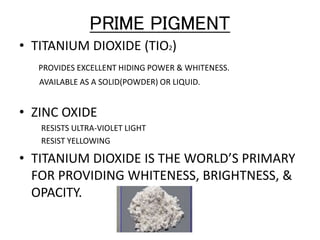

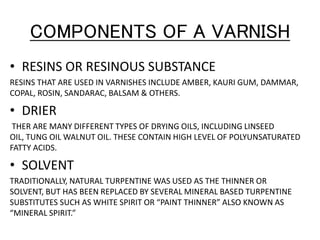

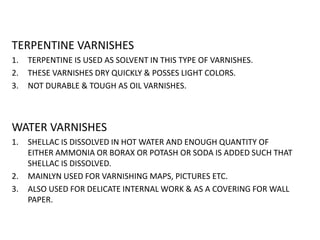

The document discusses paints and varnishes. It provides details on the typical composition of paint including pigments, resins, fillers, solvents and additives. It also describes the manufacturing process and advantages of painting. Different types of paints are outlined such as emulsion paint, cement paint, plastic paint, texture paint and acrylic paint. The document also discusses the characteristics of an ideal paint and some major paint companies. For varnishes, it covers the components, types including oil, spirit, turpentine and water varnishes as well as other types of varnishes.