This document discusses the assumptions and equations used in air-standard cycle analysis of internal combustion engines. It covers:

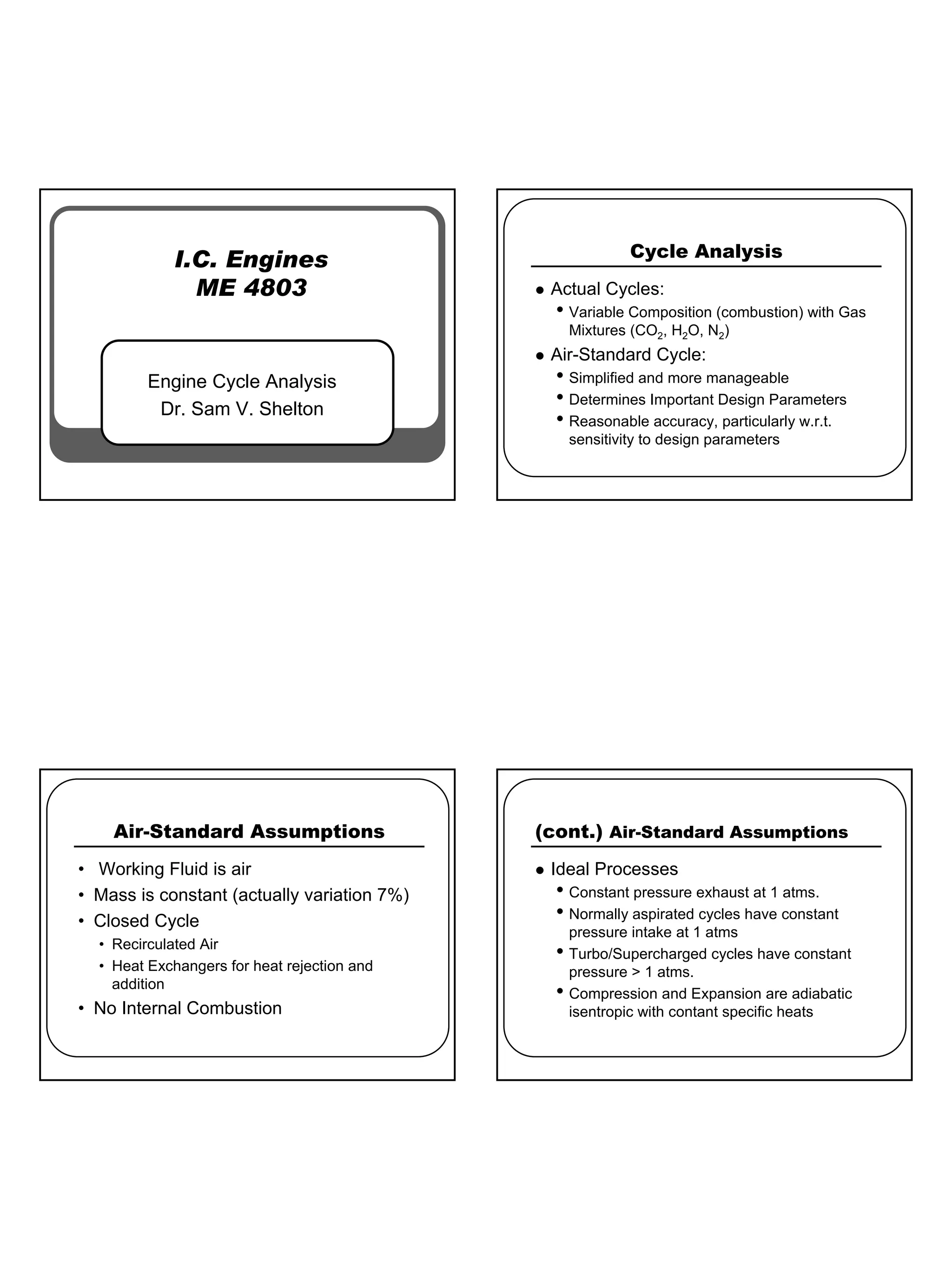

- The assumptions of the ideal air-standard cycle, including constant specific heats, reversible processes, and no combustion.

- The relevant thermodynamic equations for analyzing the Otto cycle of intake, compression, combustion, expansion, exhaust.

- How real engine cycles differ from the ideal cycle assumptions due to varying composition and properties during combustion, finite combustion duration, valve overlap effects.

- How to account for pump work from intake/exhaust pressures and residual exhaust gases in the clearance volume.

![5

Constant Volume Heat Rejection 4-5:

5 4 1 B D C

v = v = v = v

4 -5

w = 0

4 -5 o u t v 5 4 5 4 v 1 4

q = q = c (T -T )= (u -u )= c (T -T )

Blow Down

Exhaust Stroke 5-6:

5 6 0

P =P =P

5-6 0 6 5 0 6 1

w =P (v -v )=P (v -v )

Thermal Efficiency

z From Definition and Previous Process Eqns:

[ ]

t, net in out in

OTTO

v 4 1 v 3 2

η = w / q =1-( q / q )

=1- c (T -T )/c (T -T )

( )

k-1

t, 1 2

OTTO

η =1- 1/ v /v

k-1

t, c

OTTO

η =1-(1/r )

By using Isentropic Expansion and Compression Eqns:

(cont.) Thermal Efficiency

z Note: Thermal Efficiency and Work Output/cycle

t, c

OTTO

c BDC TDC

η =Function(r Only)

r compression ratio only =V /V

=

Higher Compression Ratio is Win/Win.

Higher Efficiency and Higher Power](https://image.slidesharecdn.com/4enginecyclesanalysis-210520170437/85/Engine-Cycles-Analysis-5-320.jpg)