Embed presentation

Download as PDF, PPTX

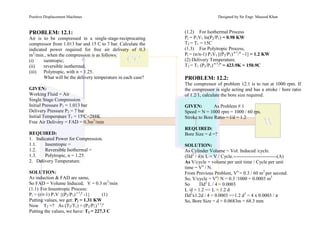

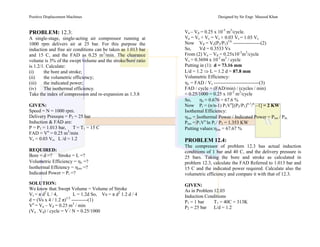

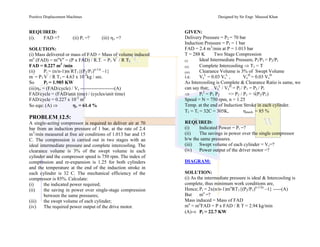

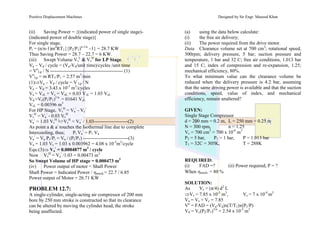

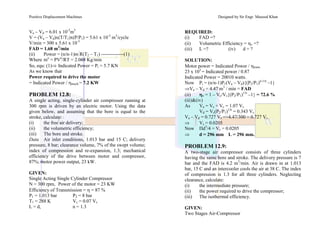

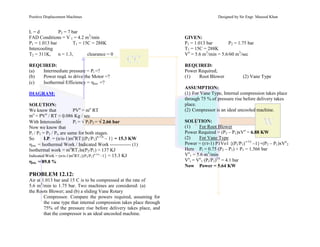

This document contains solved problems from Chapter 12 on positive displacement machines. Problem 12.1 calculates the indicated power and delivery temperature for air compression in a single-stage reciprocating compressor under isentropic, isothermal, and polytropic processes. Problem 12.2 calculates the bore size required for the compressor from Problem 12.1 running at 1000 rpm. Problem 12.3 calculates bore size, stroke, volumetric efficiency, indicated power, and isothermal efficiency for a single-stage single-acting air compressor.