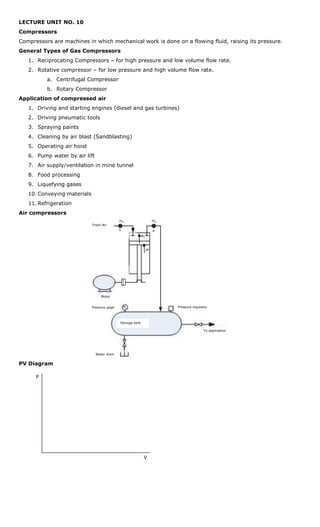

Compressors raise the pressure of a flowing fluid by mechanical work. There are two main types: reciprocating for high pressure/low flow, and rotative for low pressure/high flow. Compressed air has many industrial applications. Compressor performance is evaluated based on factors like motor efficiency, mechanical efficiency, compression efficiency, volumetric efficiency, and overall efficiency. Problems involve calculating mass flow rate, power requirements, and other parameters for given compressor specifications and operating conditions.