A reciprocating compressor takes in a gas and delivers it at a higher pressure through the cyclic action of pistons in cylinders. There are two main types - single-acting and double-acting. The compression process can follow different thermodynamic paths like isothermal, polytropic, or isentropic on a pressure-volume or temperature-entropy diagram. Isothermal compression provides the minimum work and highest efficiency. The indicated power and efficiency of a reciprocating compressor depends on parameters like mass flow rate, inlet and outlet pressures and temperatures, and the compression process path.

![rork

Jra0i

[o',

I

Ld

F.

f : t r

!

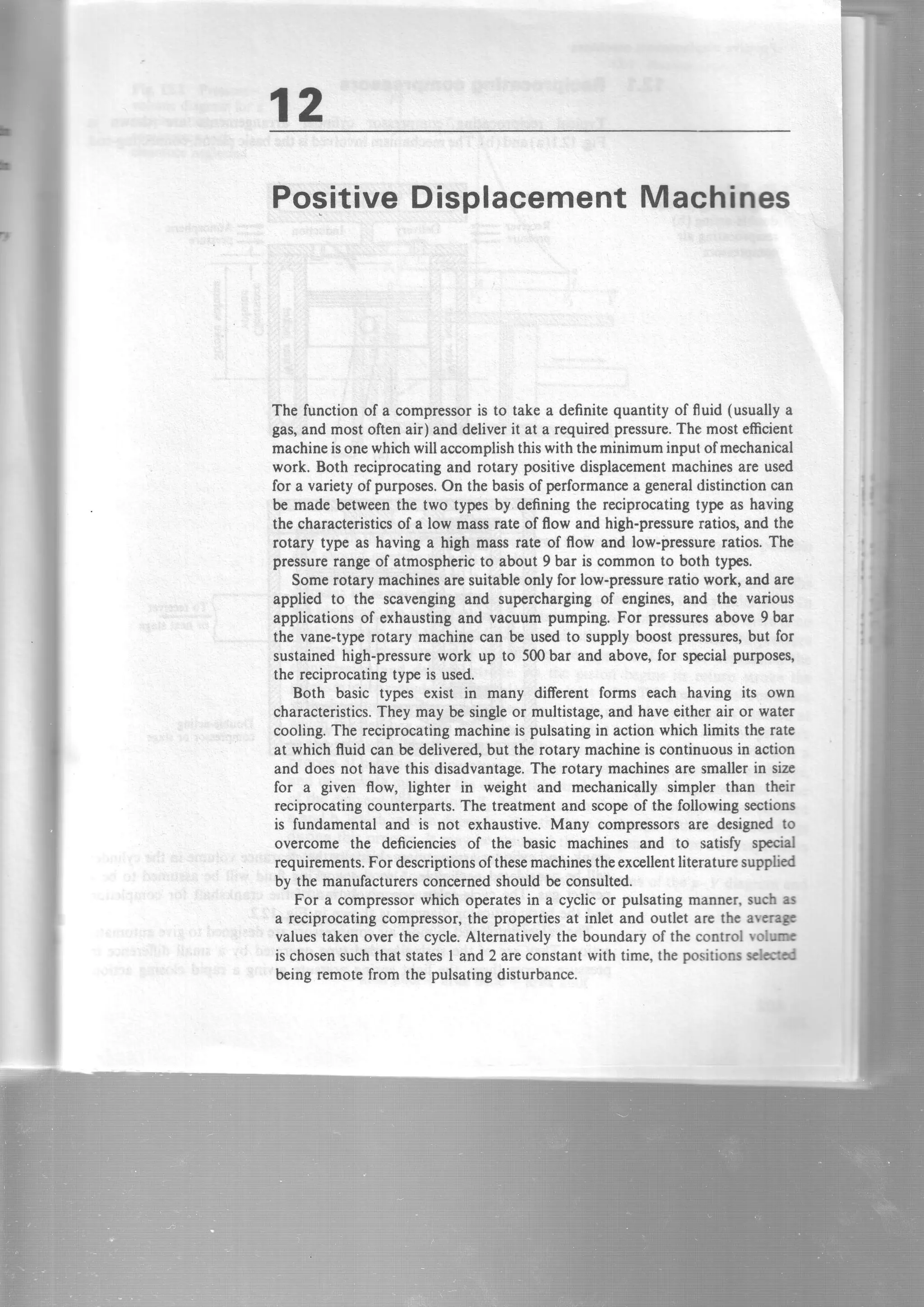

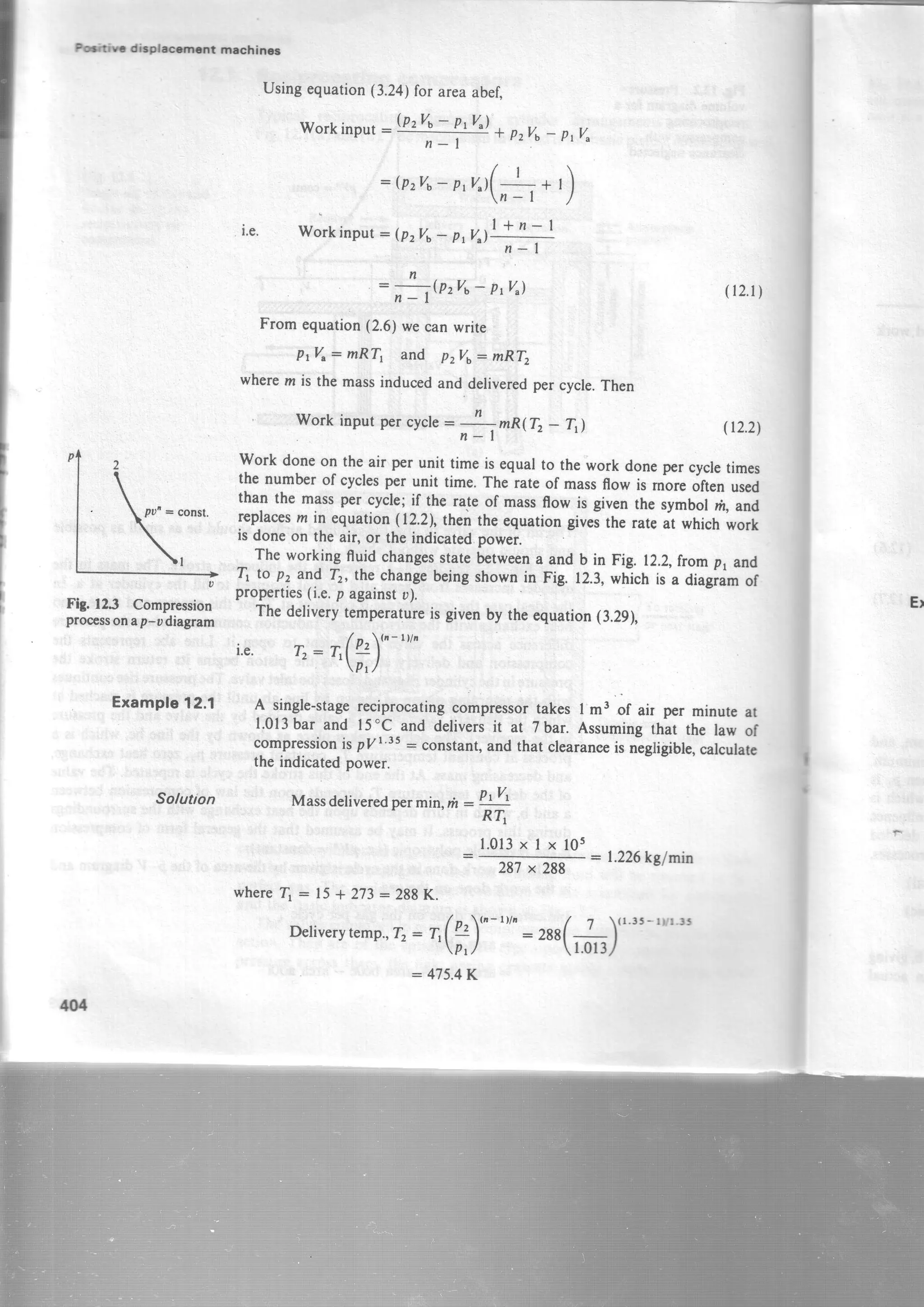

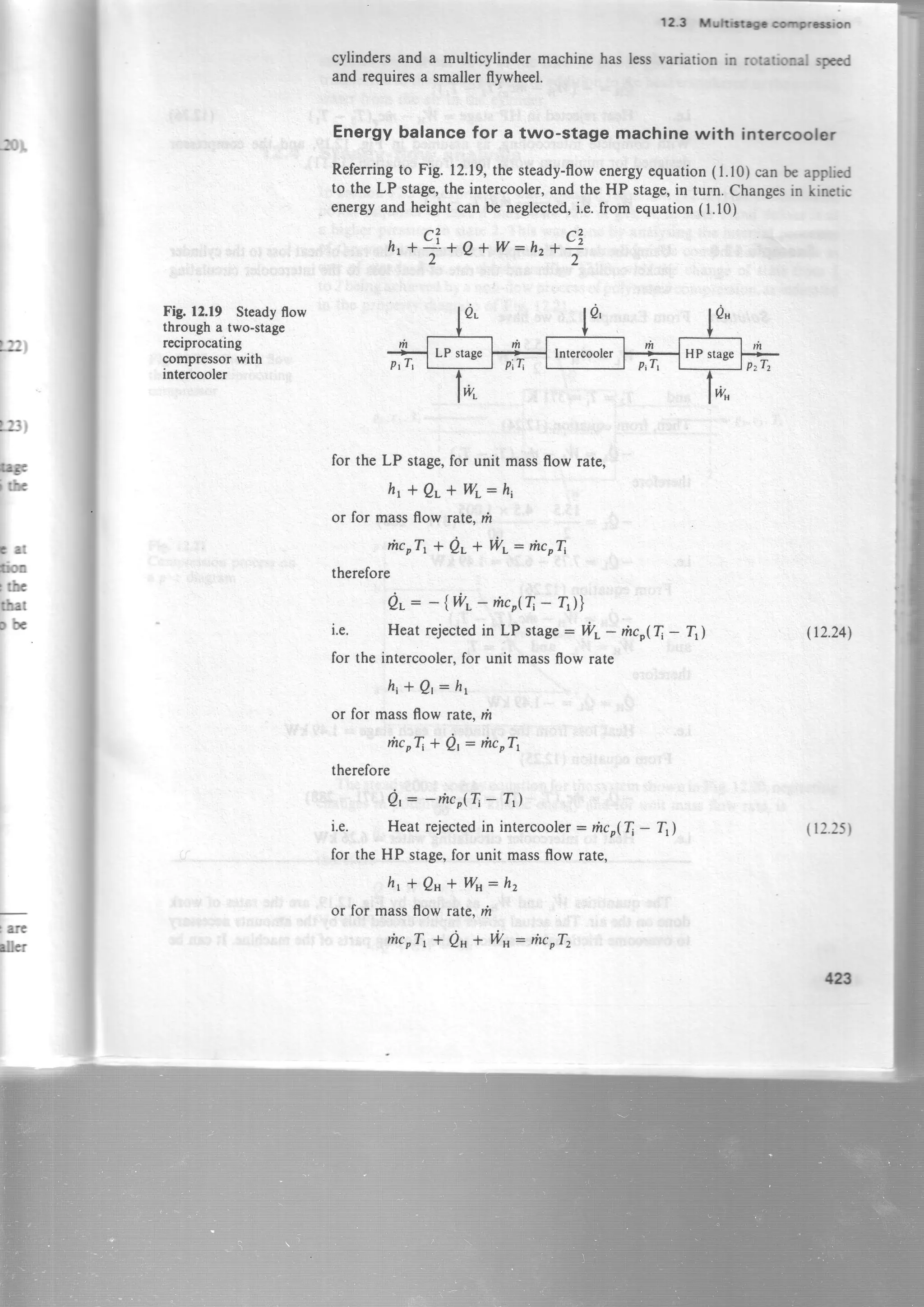

Fg. 12.4 Possible

compressionprocesses

on a p-v diagram

Example12.3

indicatedworkpercycle: p2V6,lnPf,

= PrVrhA

Pt

: mRThU

(12"8)

(l2.e)

(lzt0)

isothermalemAaryd fu

12.1 RcciwocdilrO compr=.t

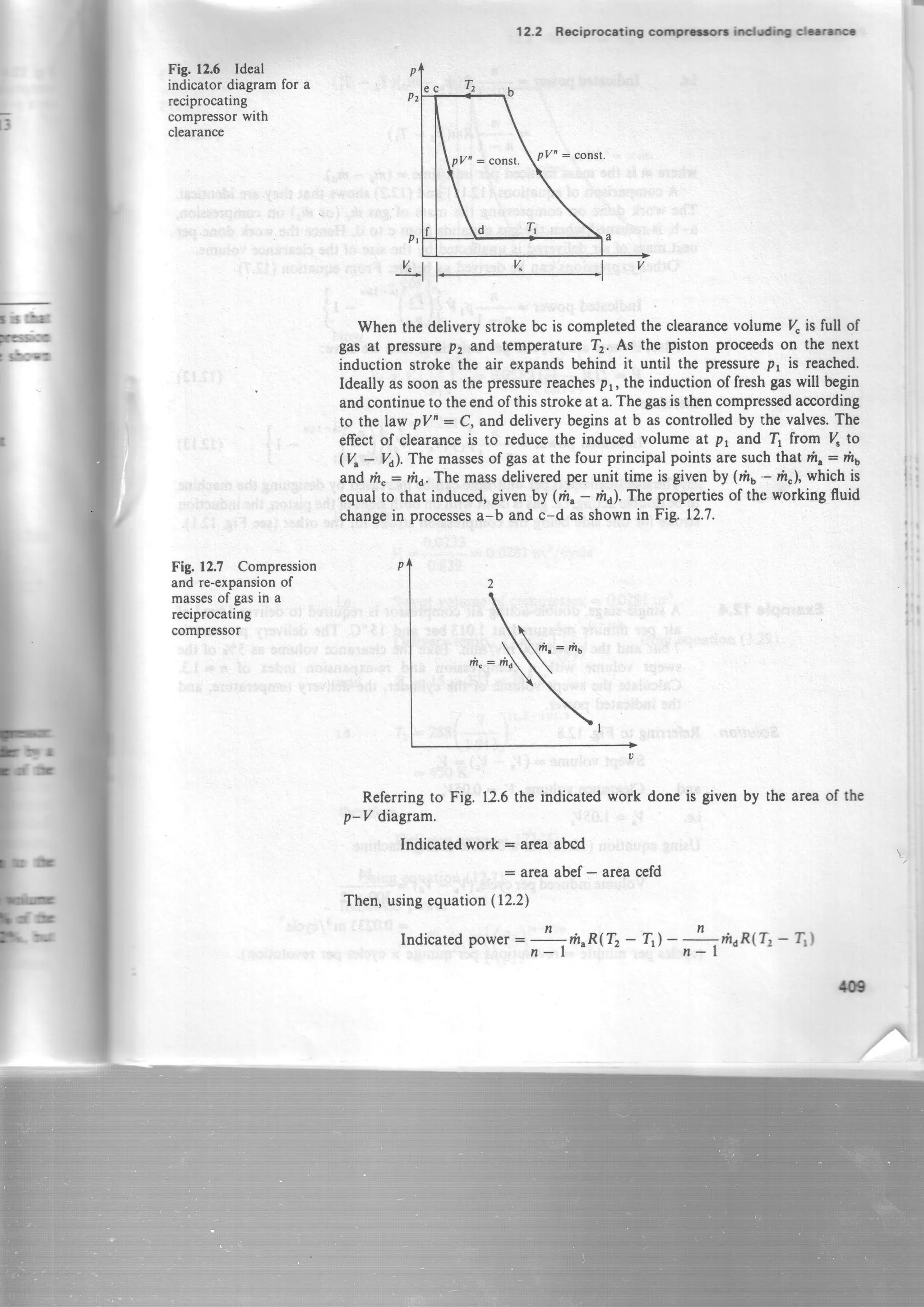

p

Pz

plz] = const.

pZ'= const.

pZ : const.

compressorthe gastemp€raturemust be kept ascloseaspossibleto its initial

value,andameansofcoolingthegasisalwaysprovided,eitherbyairor bywater.

The indicatedwork done when the gasis compressedisothermallyis givcn

by the areaablcd.

Area ablcd : ateaabref+ areabrc0e- areaad0f

Areaablef: pzVa,6& lfrom equation(3.9))'

Pr

i.e. indicatedwork perclcle= p2V6,ln!2* PtVt,- PrV"

P t

Alsop1Vr: p276,,sincethe processab1is isothermal,therefore

Pt

Whenm and %in equations(12.8)and(12.9)arethemassandvolumeinduccd

per unit time, then theseequationsgivethe isothermalpower.

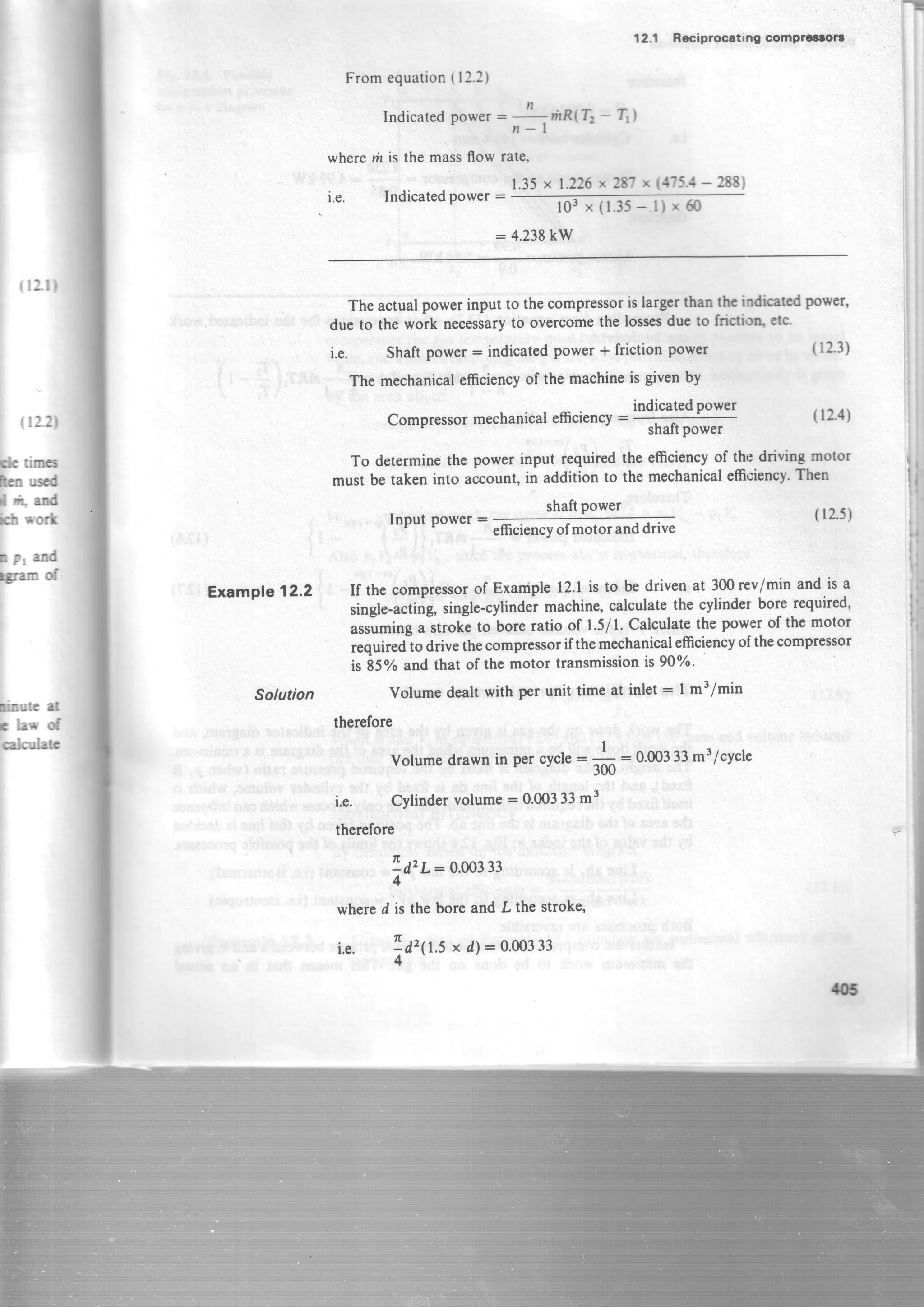

lsothermal efficiency

By definition,basedon the indicator diagram

isothermalwork

,tv43

EI

Isothermalefficiency:

Using the data of Example

compressor.

indicatedwork

l2.l calculatethe

t3](https://image.slidesharecdn.com/appliedthermodynamicsbymcconkeyed-5ch-12-160125200518/75/Applied-thermodynamics-by-mc-conkey-ed-5-ch-12-7-2048.jpg)

![Pooitive dispt.camslt rnachincc

Totalminimumpower:2 x (powerrequiredfor onestage)

:2 rrfrRr,i(A)'"-"'"- ,]

n-l tp'l )

or in termsoftheoverallpressureratiop,I p, ,wehave,usingequation(12.20|

p,_J;; _ la

P r P t V P t

therefore

rotalminimumpower:,,i*{(f)'"-""" -

This can be shownto extendto z stagesgiving in general,

rotalminimumpower= r-!-,antte)" "'""-'] tr2'22)

Pressureratioforeachstage:(fi)"'

'l

(12.23)

Hencethecondition for minimum work is that the pressureratio in eachstage

is the sameand that intercoolingis complete.(Note that in Example12.6the

information givenimpliesminimum work')

Example 12.7 A three-stage,single-actingair compressorrunning in an atmosphereat

t.0t3bar uiO tst tur a freeair deliveryof 2.83m3/min.The suction

pressureand temperatureare0.98bar and 32'C respectively.Calculatethe

indicatedpoweriequired,assumingcompleteintercooling n: 1.3,and that

the machineis designedfor minimum work. The deliverypressureis to be

70bar.

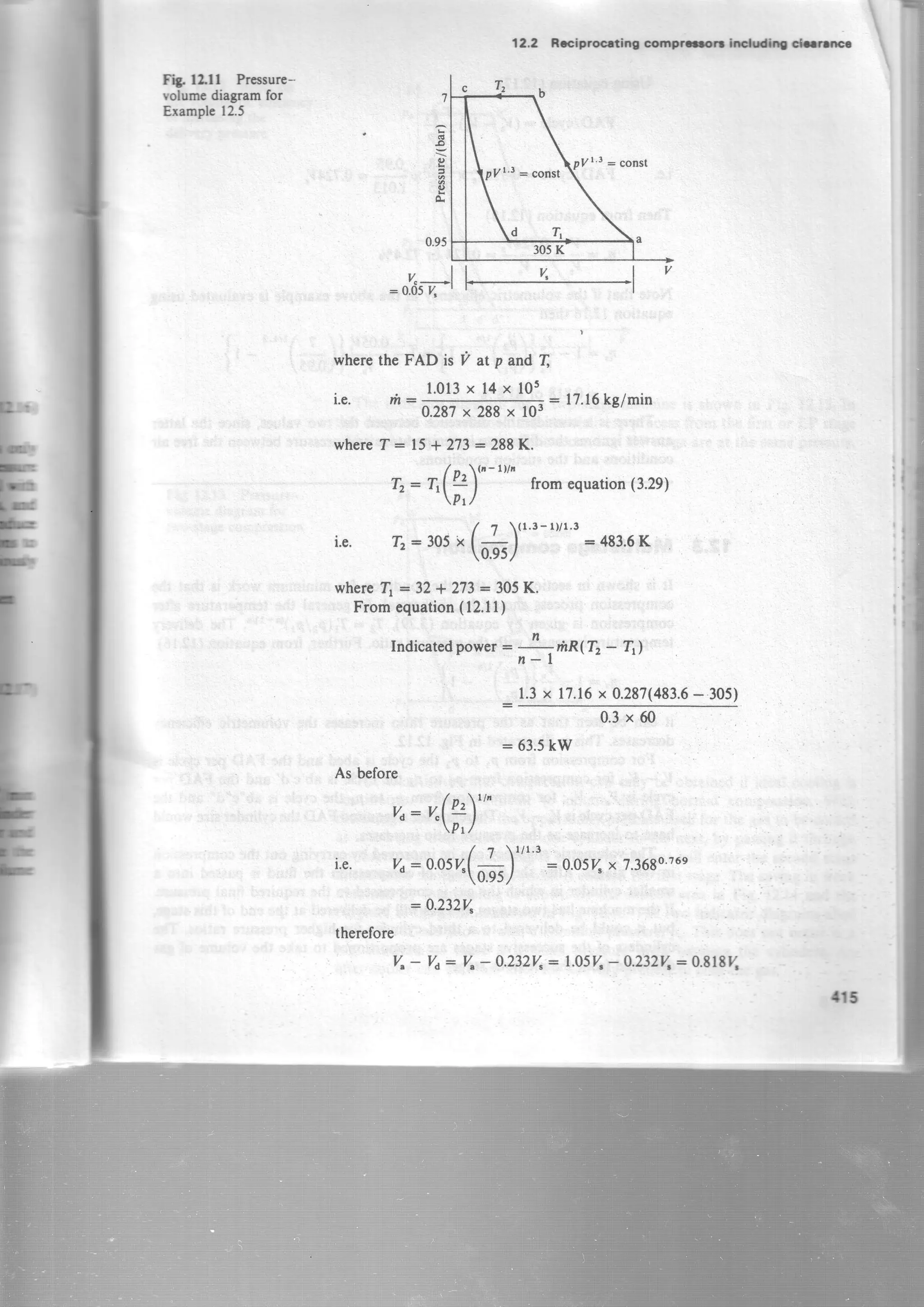

1.013x tos-I?'gt : i.47kg/minSolution Massof air delivercd- 1Y=:

RT

whereT=15*273:288K.

Thcnusingequation(12.221

TotalindicatedPower

287x288

=,{an"te)""'"-,}

=, *

H "

ry.9;ig{(#)"

rY(3x13}

- r}

=24.2kW

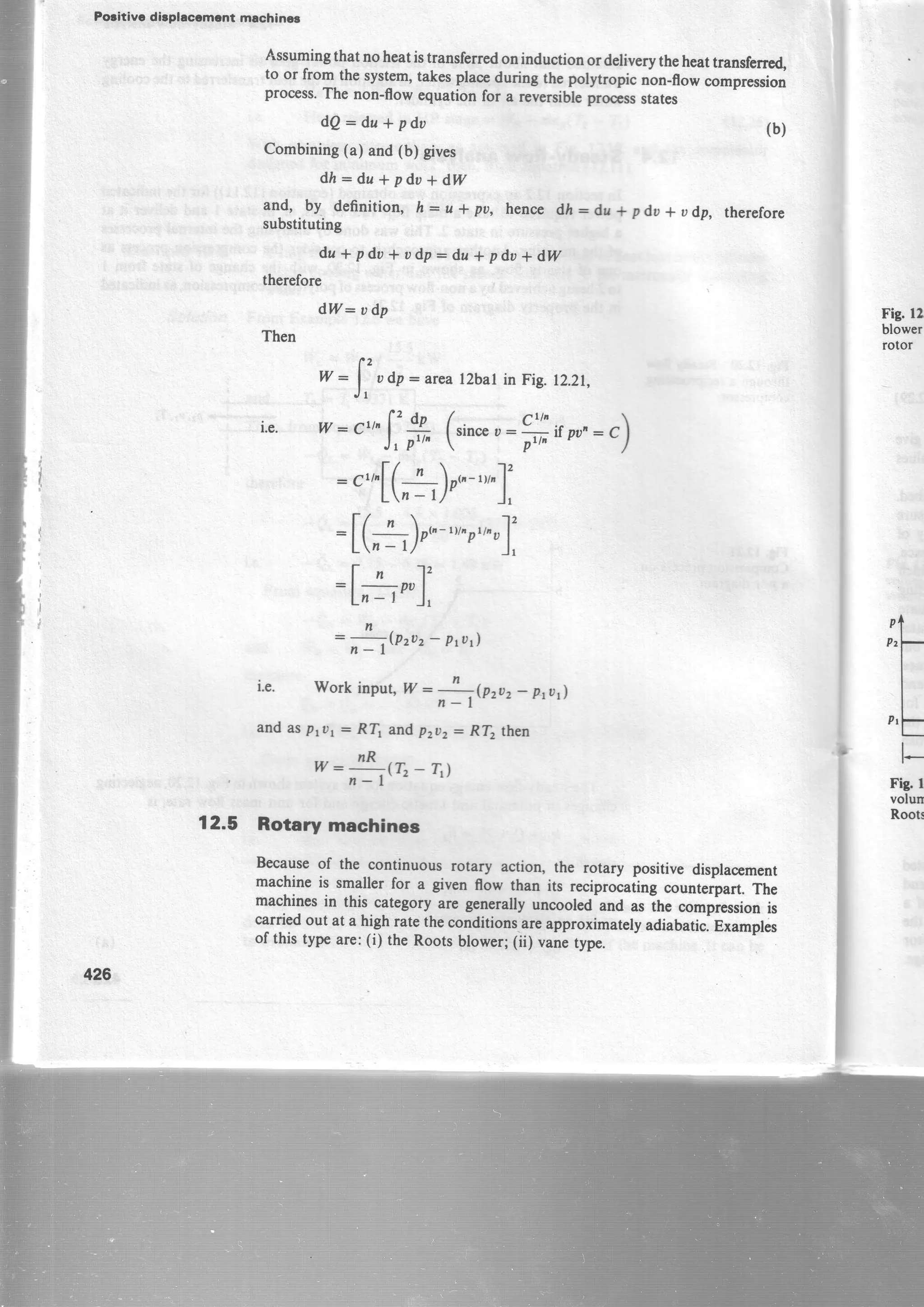

Besidesthe benefitsof multistagecompressionalreadydealt with thereare

also mechanicaladvantages.The higher pressuresare confinedto the smaller

422

F?

thrt

rcdt

ooE

intc](https://image.slidesharecdn.com/appliedthermodynamicsbymcconkeyed-5ch-12-160125200518/75/Applied-thermodynamics-by-mc-conkey-ed-5-ch-12-22-2048.jpg)

![lEi

' rt2lf

Irod]ai

Thtrr-

iroiH

l i l

dq

-

3pth

C

tur-l

rcT

pt ir &t

lir.*d

FE$r

i:r*r

hrl r

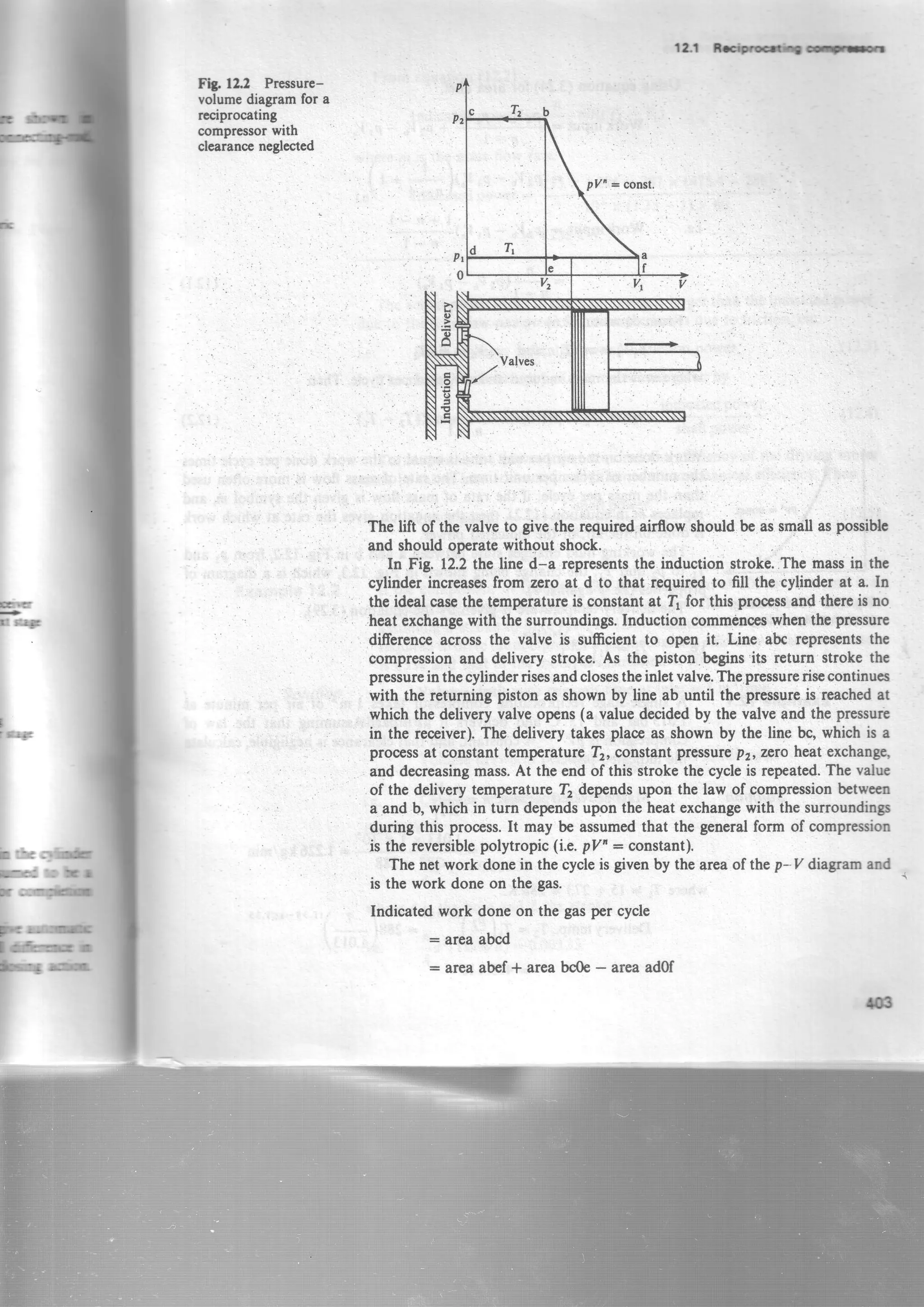

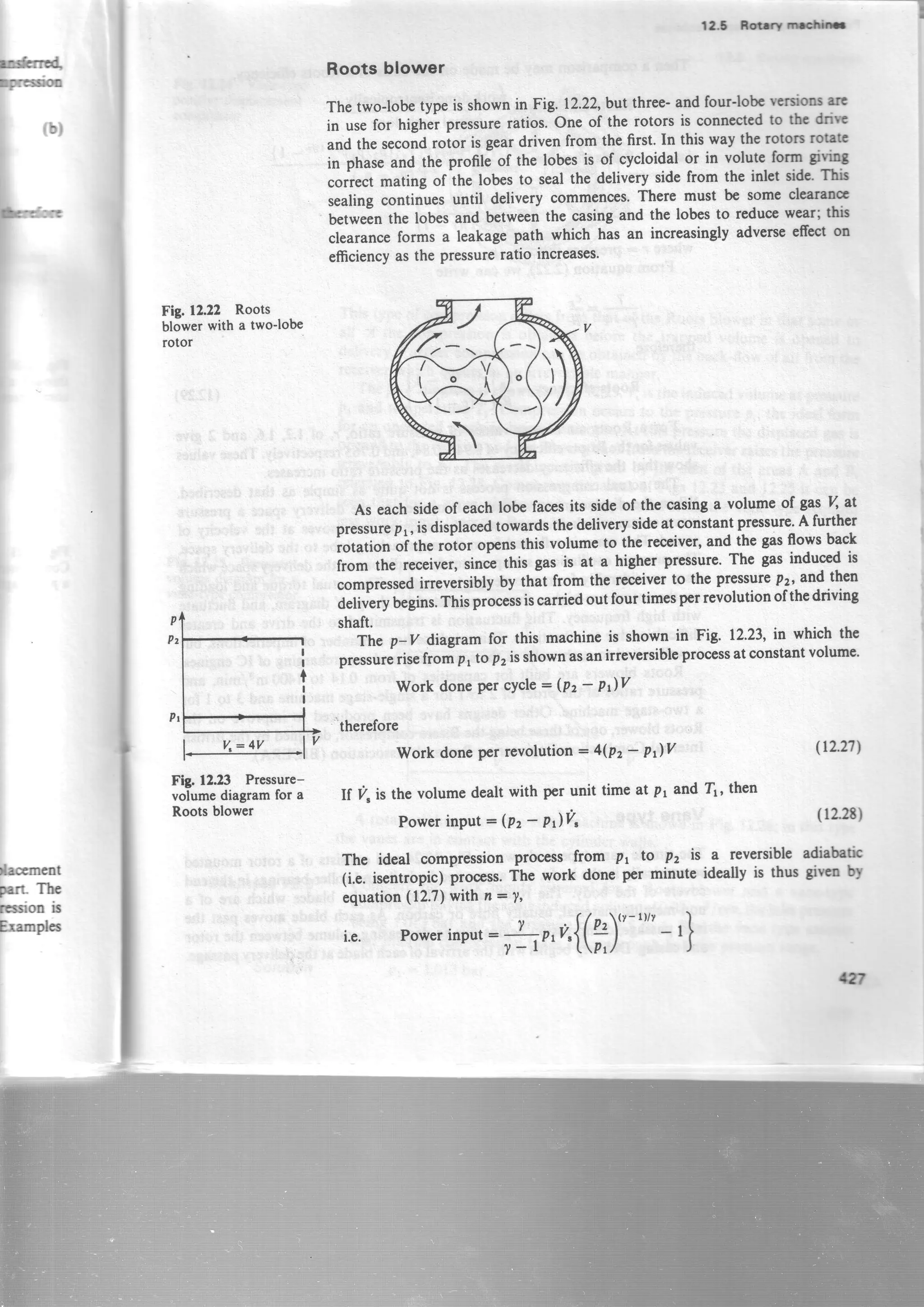

Fig 12.24 Vane-type

positivedisplacement

compressor

F.ry.12,25 Pressure-

volumediagramfor a

YAne-typecompressor

Example 12.9

Solution

12.6 nArr rn*r

IEl,

Krq

t n ,

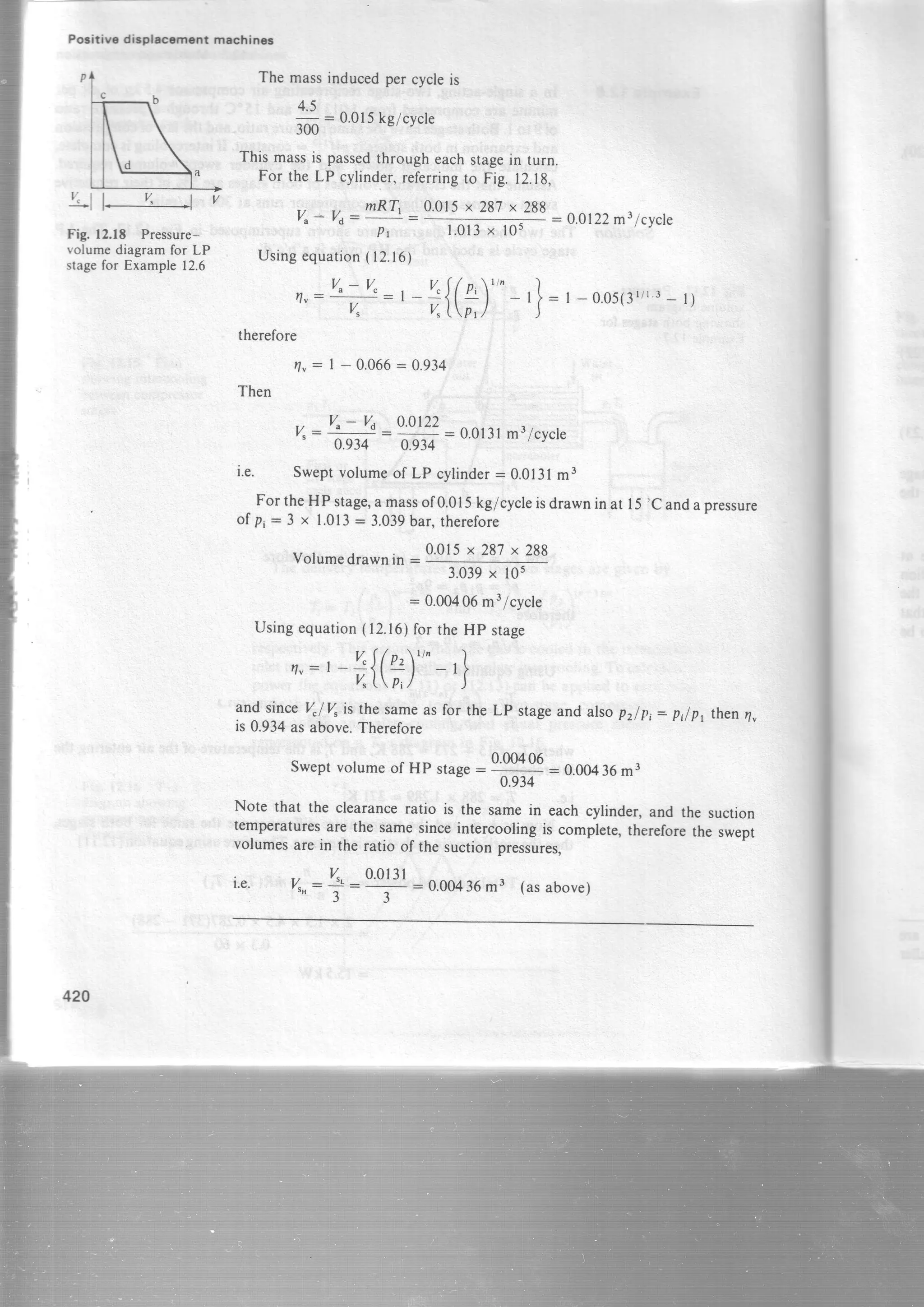

This type of compressiondiffersfrom that of the Rootsblowerin that someor

all of the compressionis obtained beforethe trapped volume is openedto

delivery.Further compressioncanbeobtaineduy ttri back-flowof air from the

receiverwhich occursin an irreversiblemanner.

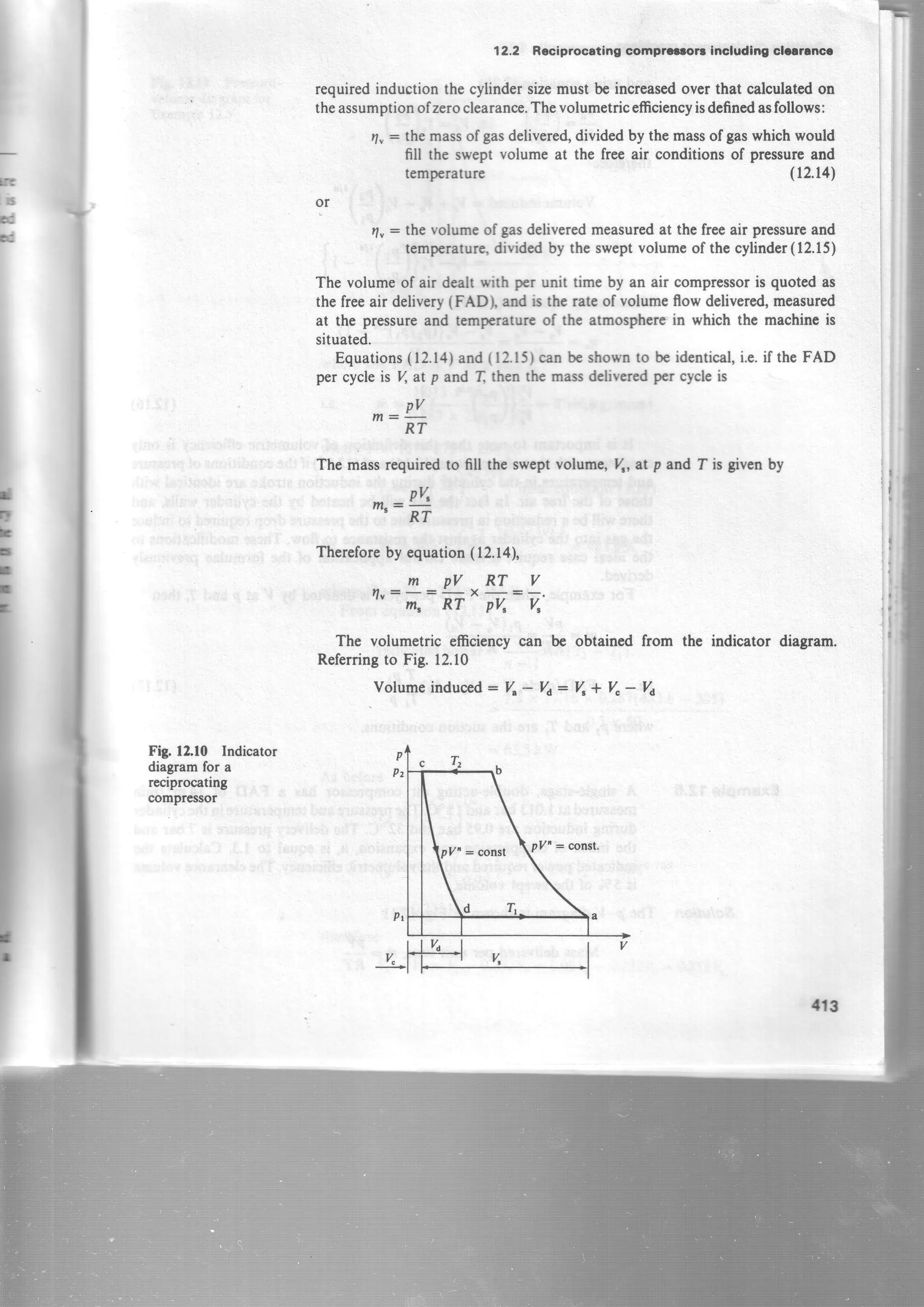

Thep-v diagramis shownin Fig. rz.2s.v"is theinducedvolumear pressure

pr and temperature[. compressionoccursto the pressurep,, thc idealform

for an uncooledmachinebeingisentropic.At this prissurethl'displacedgasis

openedto thereceiverandgasflowing backfrom thereceiverraisejtheprJrrur"

irr-eversiblyto pr. The work input is given by the sum of the areasA and B,

referringto Fig. 12.25.comparing the areasof Figs 12.23and 12.2sit can be

seenthat for a given airflow and given pressureratio the vanetyp€ requires

lesswork input than the Roots blower.

A rotary slidingvanetwo-stagemachineis shownin Fig. 12.26;inthis typc

the vanesare in contact with the cylinder walls.

compare the work inputs required for a Roots blower and a yane-typc

compressorhavingthesameinducedvolumeof 0.03m3/rev,theinlct prc rc

being 1.013bar and the pressureratio 1.5to l. For the vaoetypc ernc

that internal compressiontakesplacethrough half the pressurerrqla

Pr : 1.013bar](https://image.slidesharecdn.com/appliedthermodynamicsbymcconkeyed-5ch-12-160125200518/75/Applied-thermodynamics-by-mc-conkey-ed-5-ch-12-29-2048.jpg)