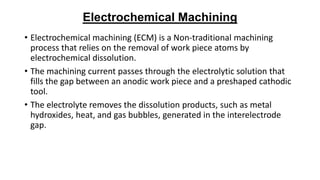

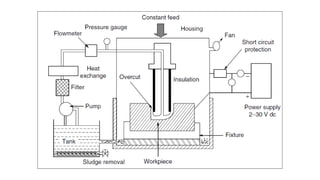

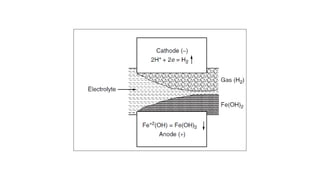

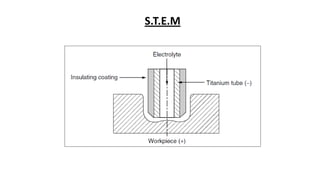

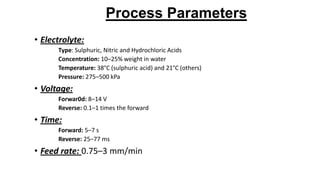

This document discusses shaped tube electrolytic machining (STEM), which is a variation of electrochemical machining (ECM) that can produce small holes with high depth-to-diameter ratios in electrically conductive materials. STEM uses a cathodic tool in the shape of a conducting cylinder with an insulating coating to drill holes in an anodic workpiece when an electric potential is applied through an electrolyte, typically an acid. The document outlines the STEM process, parameters including electrolytes, voltage, time and feed rate, capabilities including hole size and tolerances, advantages, limitations, and applications for drilling cooling holes in parts like turbine blades.