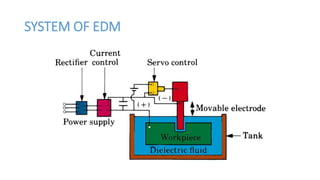

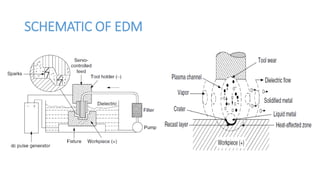

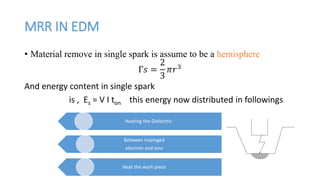

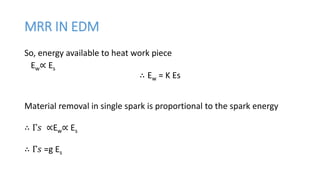

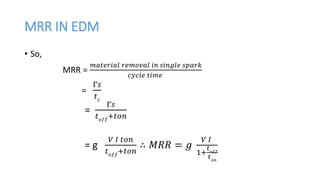

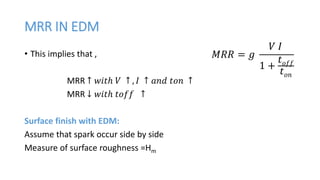

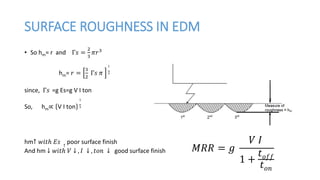

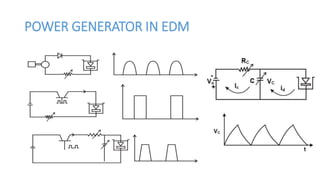

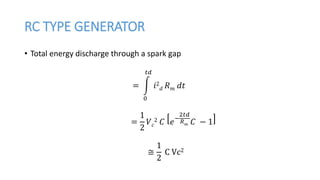

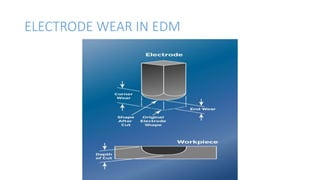

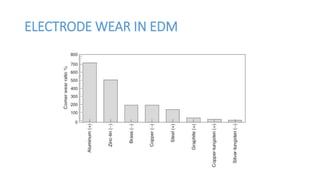

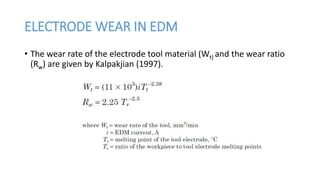

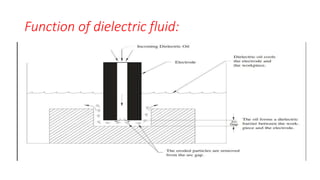

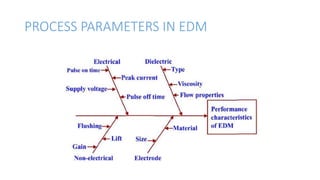

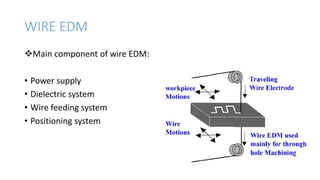

The document provides information about electric discharge machining (EDM). It discusses the history of EDM, which began in the 18th century with observations of erosion from electric discharge. EDM was developed in the 1940s and commercialized in the 1950s. The document describes the basic working principles of EDM, including how material is removed through electric sparks between electrodes. It also covers aspects like power generators, material removal rates, surface roughness, electrode materials and movement.