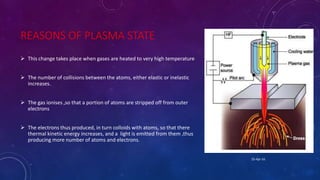

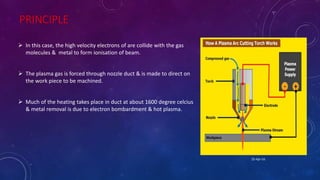

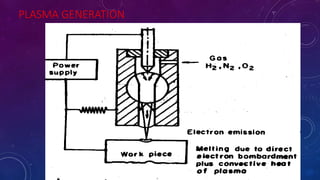

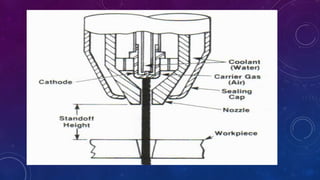

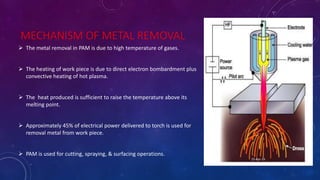

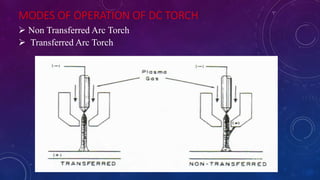

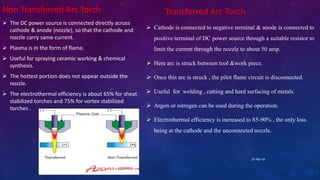

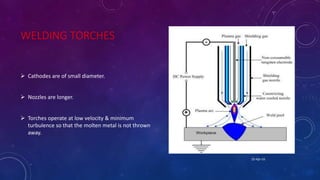

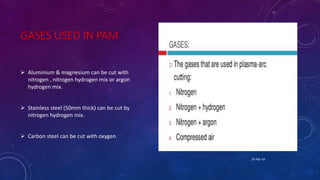

The document discusses plasma arc machining (PAM). PAM uses a high-velocity jet of hot plasma to cut through electrically conductive materials. It is commonly used in fabrication shops for precision cutting of metals. PAM provides high-speed, precise cuts at a lower cost compared to other machining methods. The document then goes on to describe the process of generating plasma using high heat, and the mechanisms by which plasma removes metal through heating and melting. It also discusses the various torch designs and parameters that affect the performance of PAM.