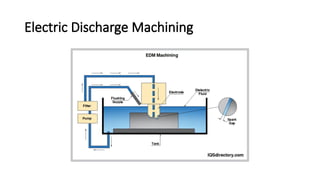

Electric discharge machining (EDM) is a non-traditional manufacturing process that removes material from workpieces through controlled electrical discharges, predominantly used for machining hard or intricate materials. The process offers high precision, minimal burrs, and works without physical contact, although it has a slower material removal rate and is limited to conductive materials. Applications span industries including aerospace, automotive, medical, and electronics, with variations like wire cut EDM and micro-EDM for specialized, detailed work.