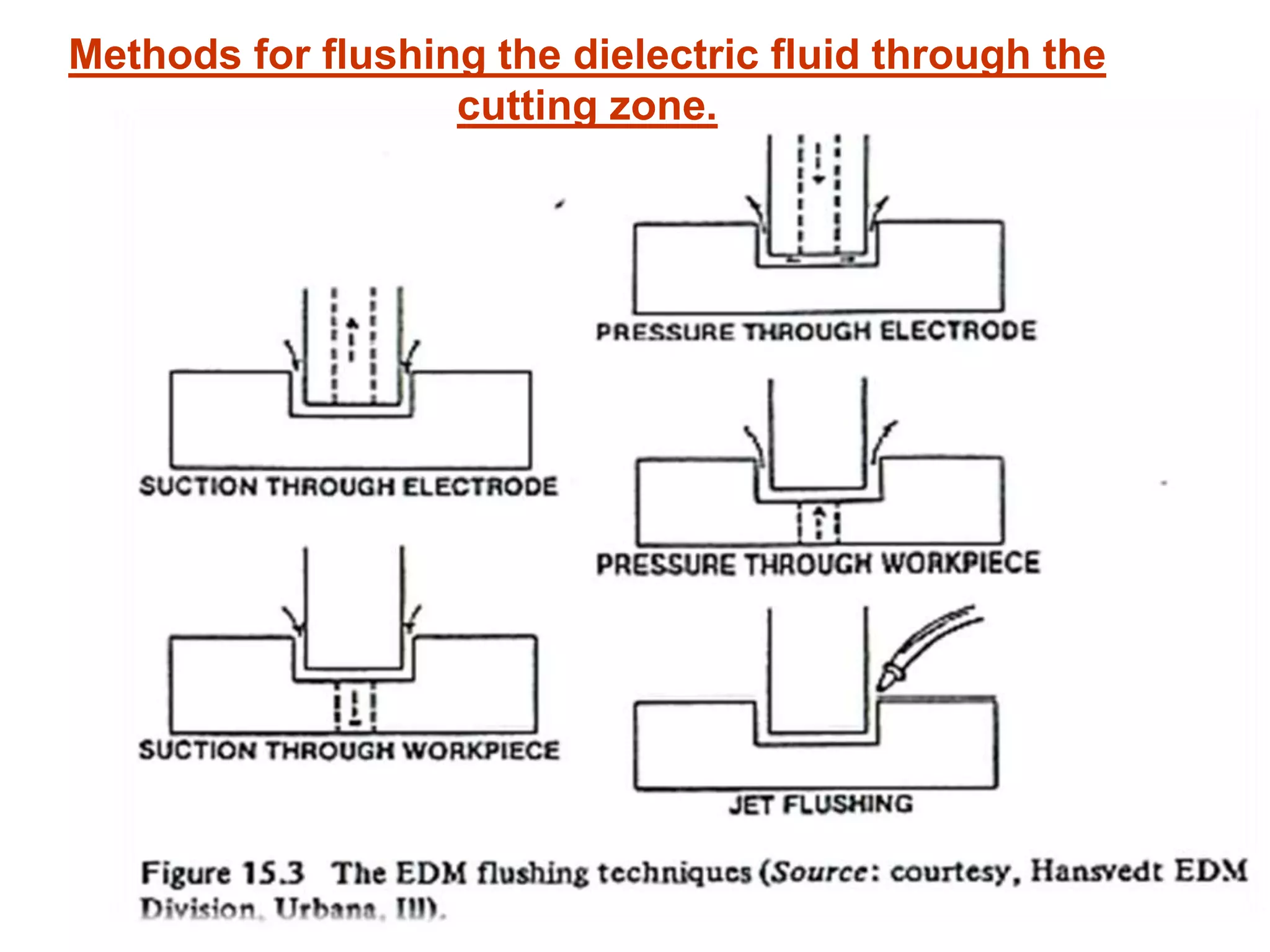

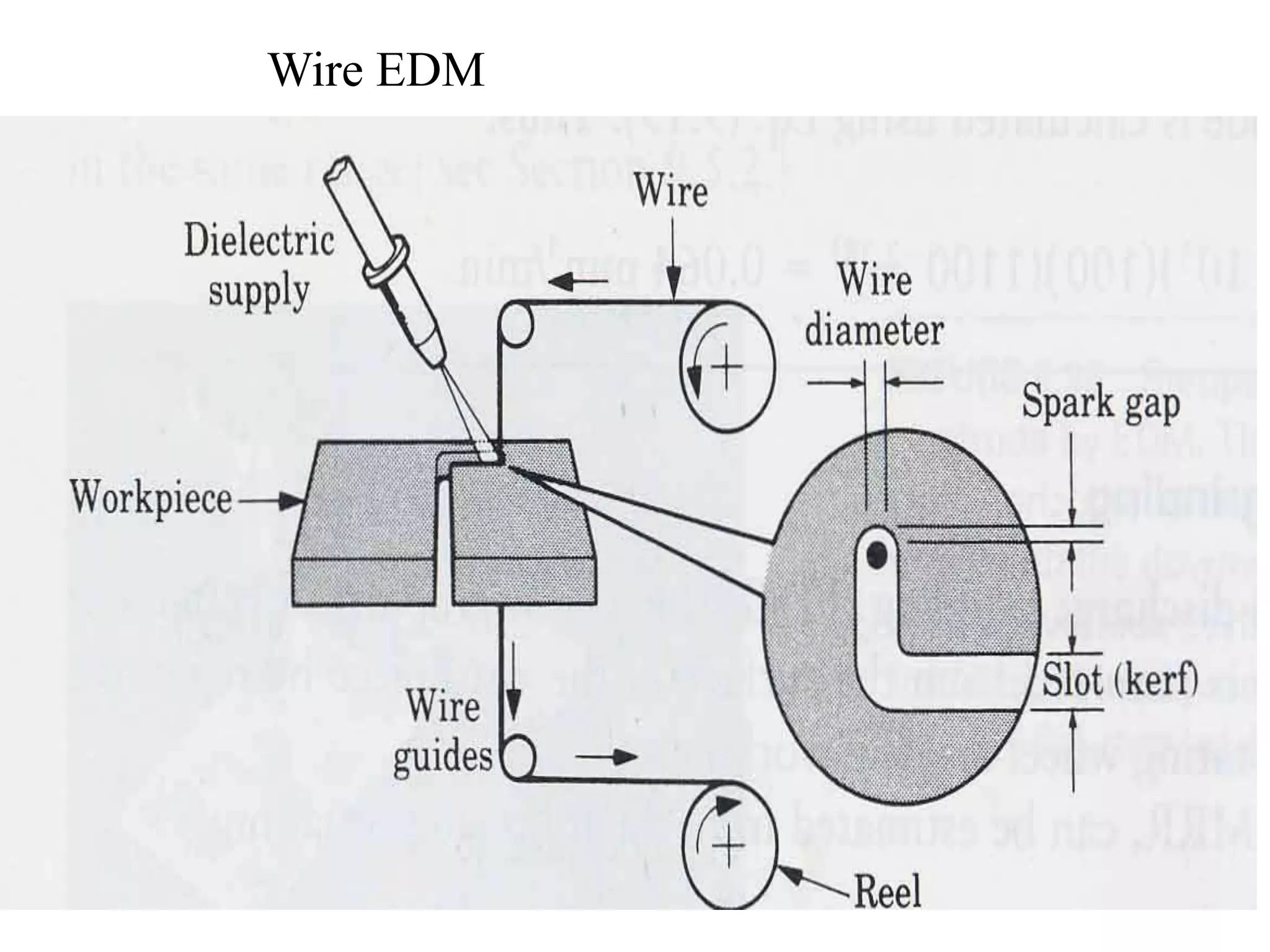

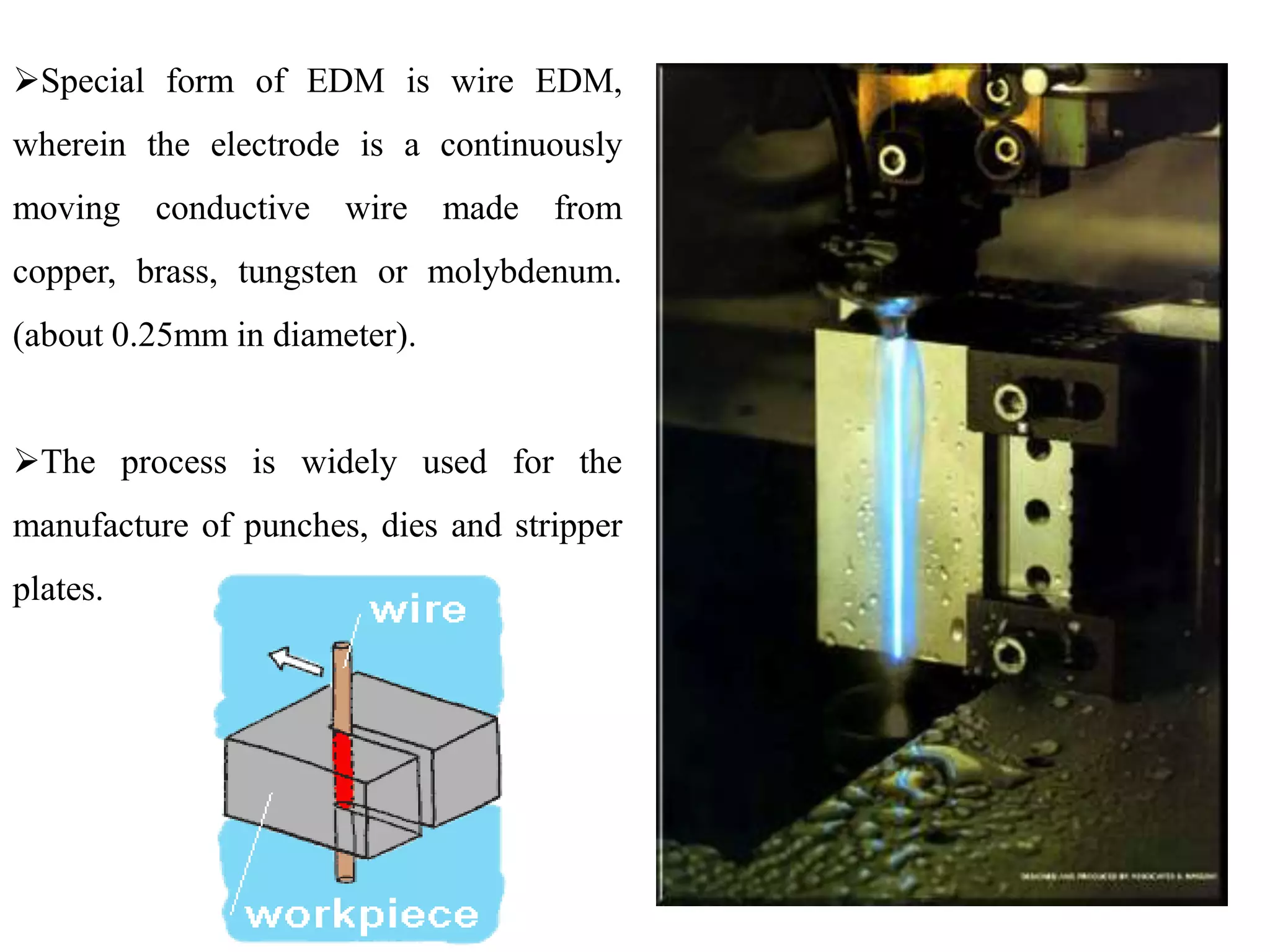

Wire electrical discharge machining uses a thin electrically charged wire as an electrode to cut conductive materials precisely through controlled electrical sparks. During the process, hundreds of thousands of sparks per second melt and vaporize tiny amounts of material from both the wire and workpiece. The wire is continuously advanced and small debris is flushed away by a dielectric fluid, allowing complex shapes to be cut without physical contact between the wire and workpiece. This results in parts with an excellent surface finish and no burrs.