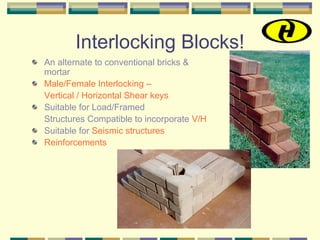

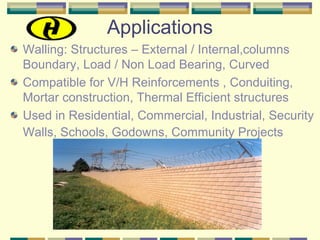

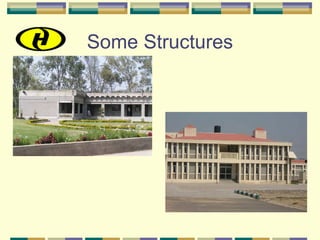

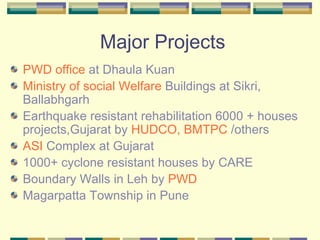

The Hydraform building system is an eco-friendly and energy efficient building technique that uses interlocking blocks made from fly ash or soil-cement. It was established in 1988 in South Africa and has since been adopted in over 40 countries. The system uses no mortar in construction, allows for faster building, and produces structures with high strength, thermal efficiency, and finishes without plaster. Projects using Hydraform blocks can be residential, commercial, or industrial applications. It provides a sustainable alternative to burnt brick masonry.