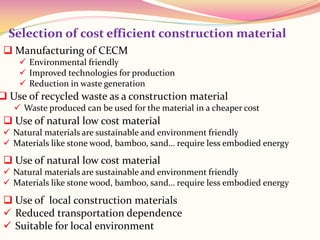

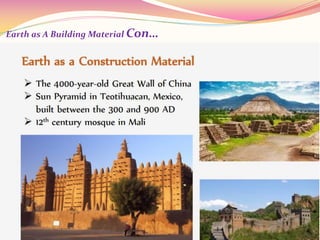

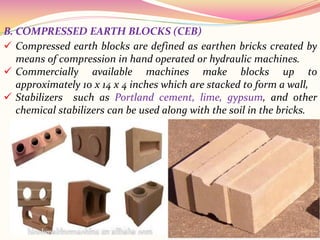

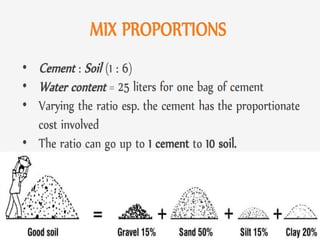

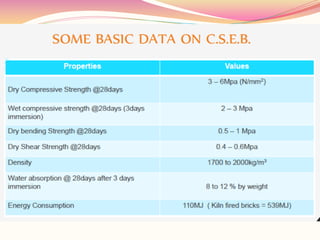

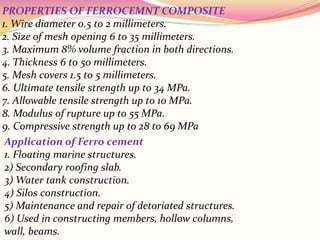

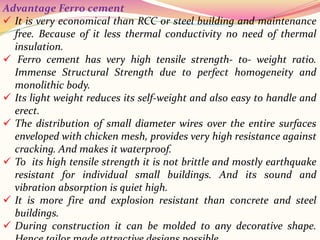

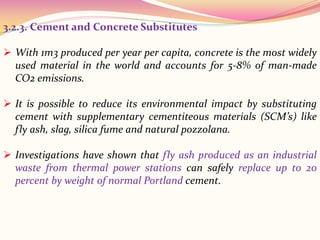

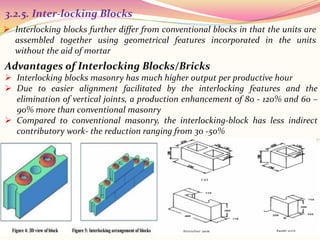

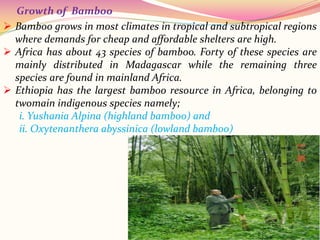

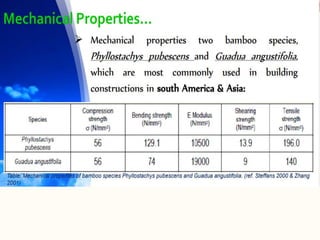

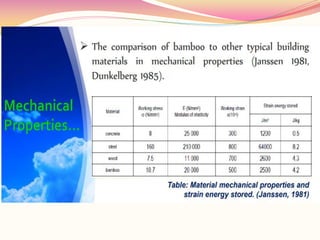

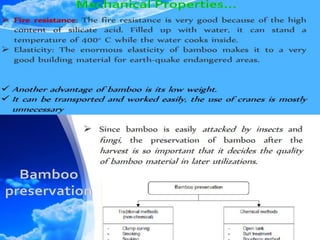

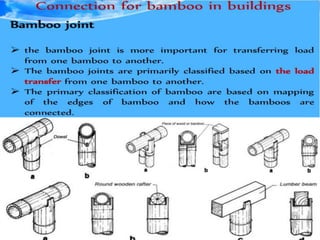

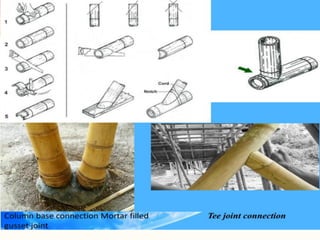

This document discusses various low-cost and sustainable construction materials that can be used for cost-efficient construction. It covers materials like earth/mud, compressed earth blocks, ferrocement, cement and concrete substitutes, wood/timber substitutes, interlocking blocks, bamboo, and prefabricated construction. Traditional materials like mud are inexpensive but not durable, while stabilized materials like compressed earth blocks provide improved strength and water resistance at low cost. Ferrocement and prefabricated construction allow for fast, inexpensive assembly. Using materials that are locally available and have low embodied energy, like bamboo, earth, and wood substitutes, supports sustainable construction.