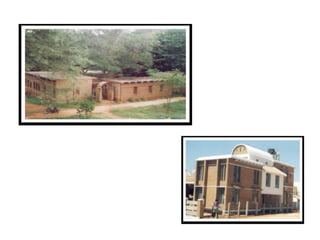

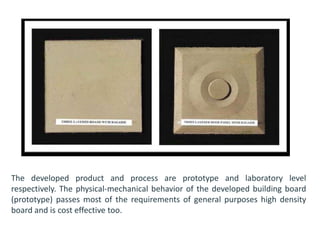

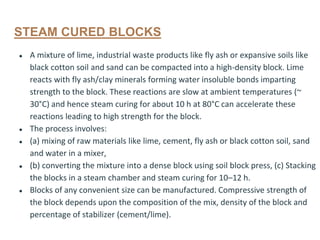

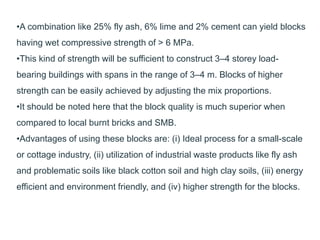

The document discusses the evolution and impact of alternative building materials, emphasizing the need for sustainable solutions in construction due to the rising demand for housing and its associated environmental challenges. It highlights various eco-friendly materials such as stabilized mud blocks and composites made from agricultural waste as viable alternatives to conventional materials like cement and steel. The document concludes by calling for organized efforts to promote the adoption of these sustainable practices within the construction industry to ensure long-term environmental benefits.