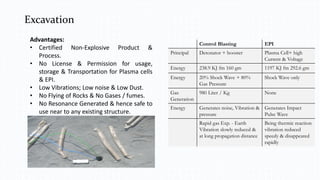

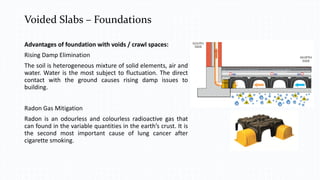

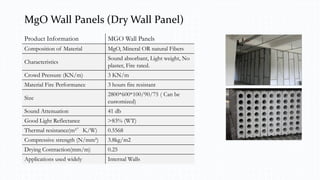

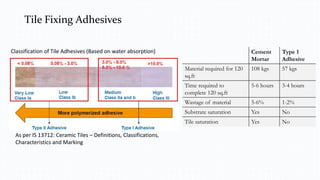

The document outlines advancements in construction technology, covering various aspects such as construction planning, building materials, and innovative excavation techniques. Key innovations include plastic and hybrid formwork, non-explosive rock fragmentation methods, and improved material properties for lightweight concrete and adhesives. These developments focus on enhancing safety, efficiency, and sustainability in construction processes.