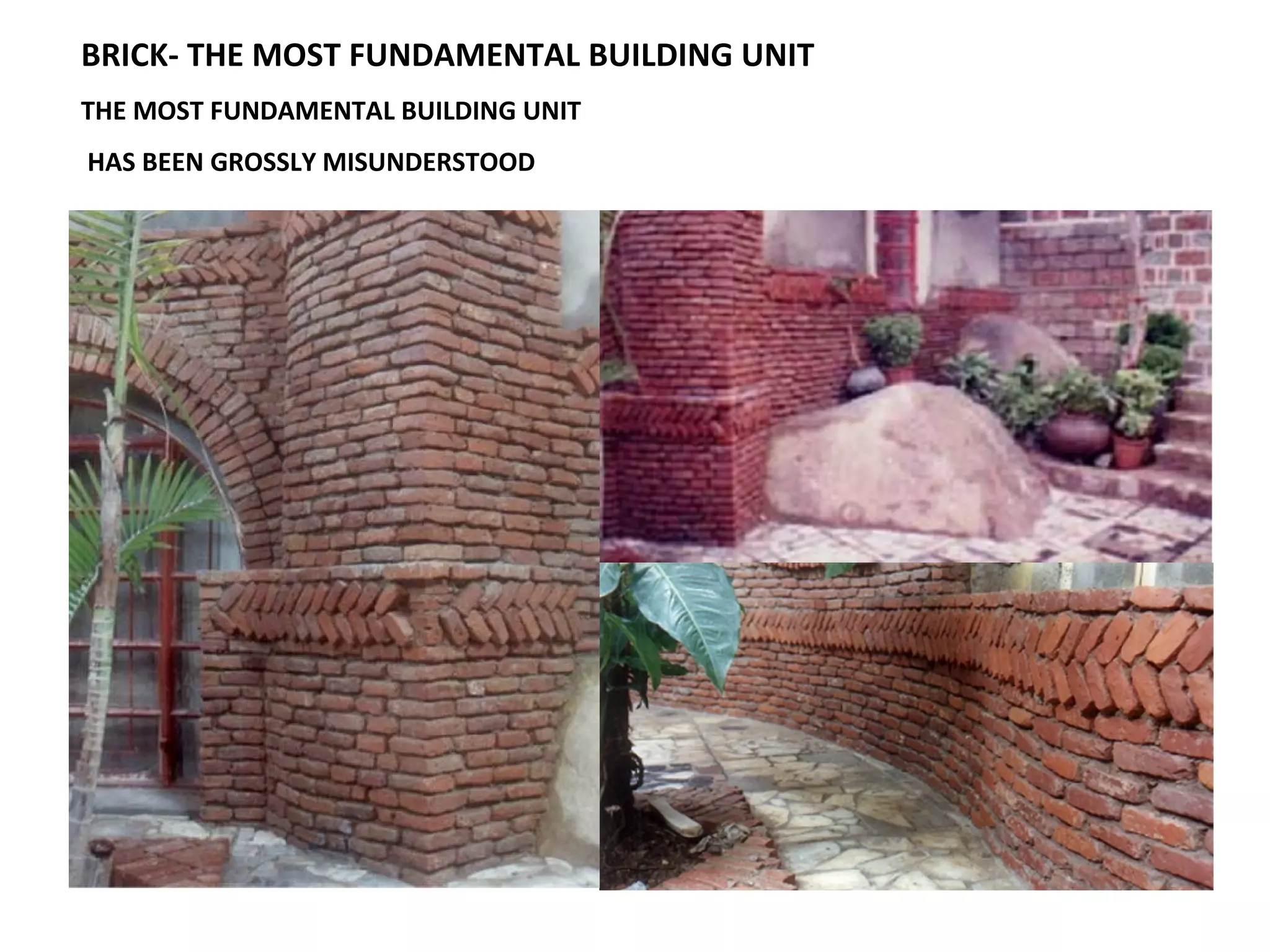

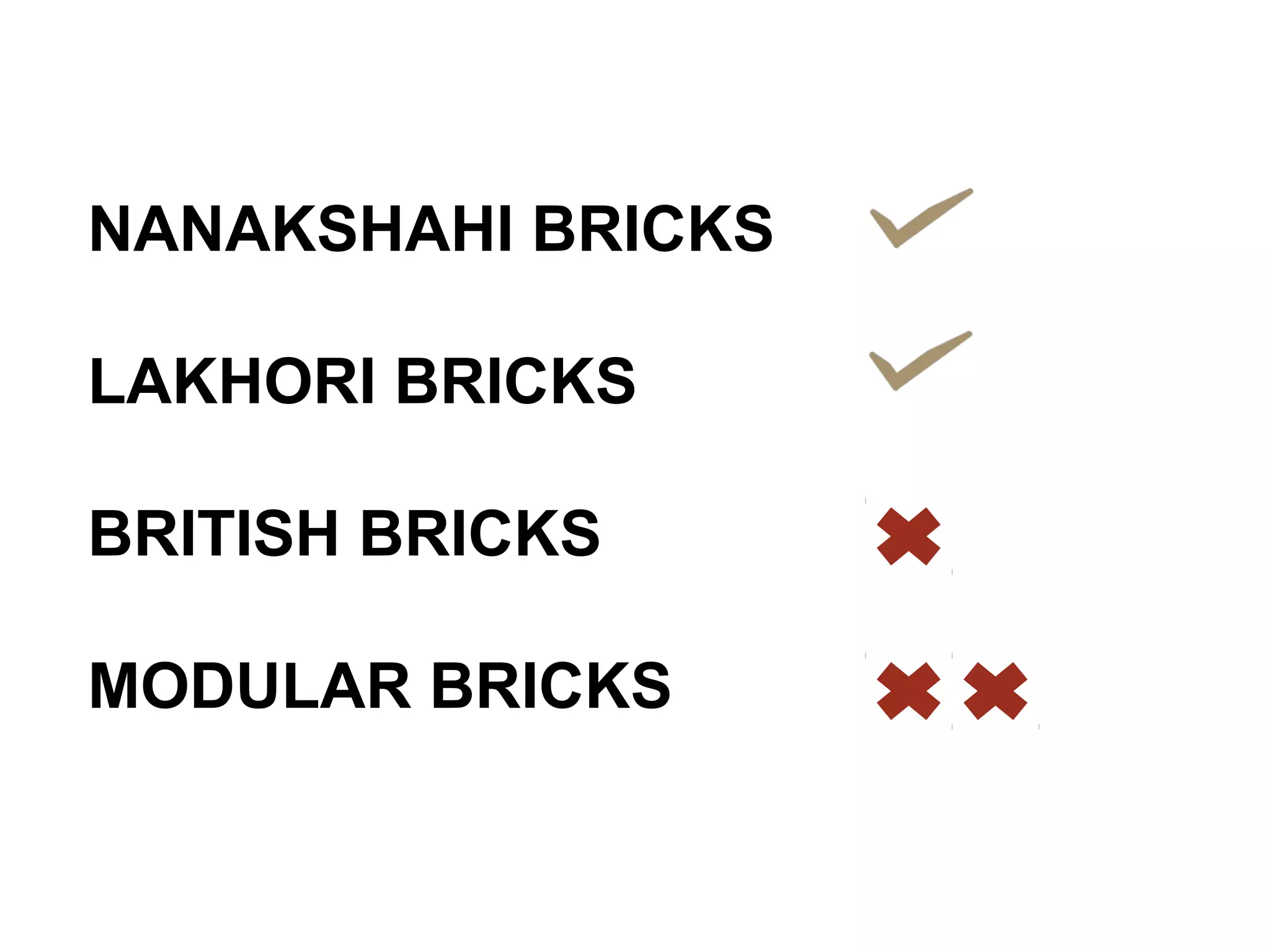

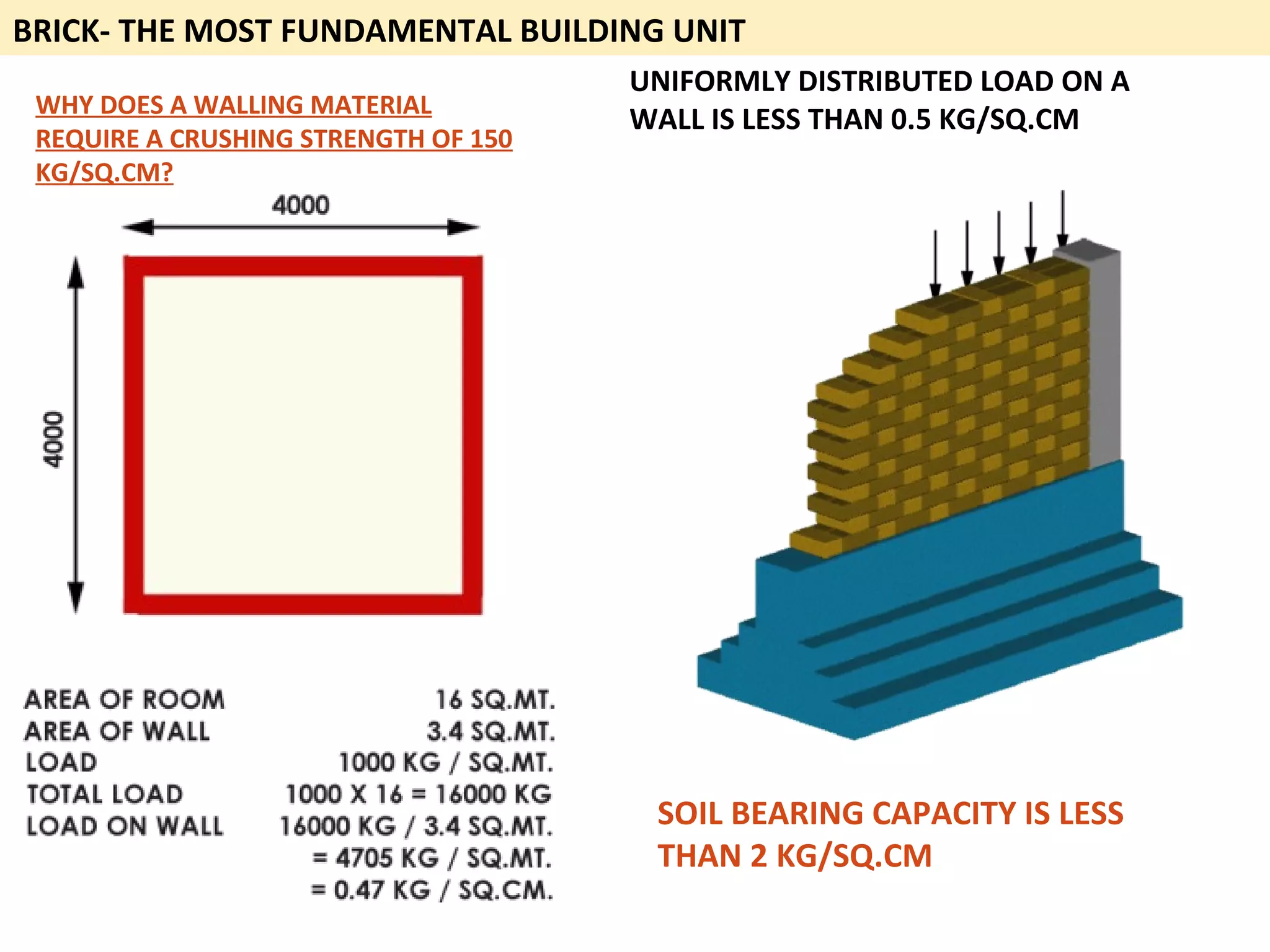

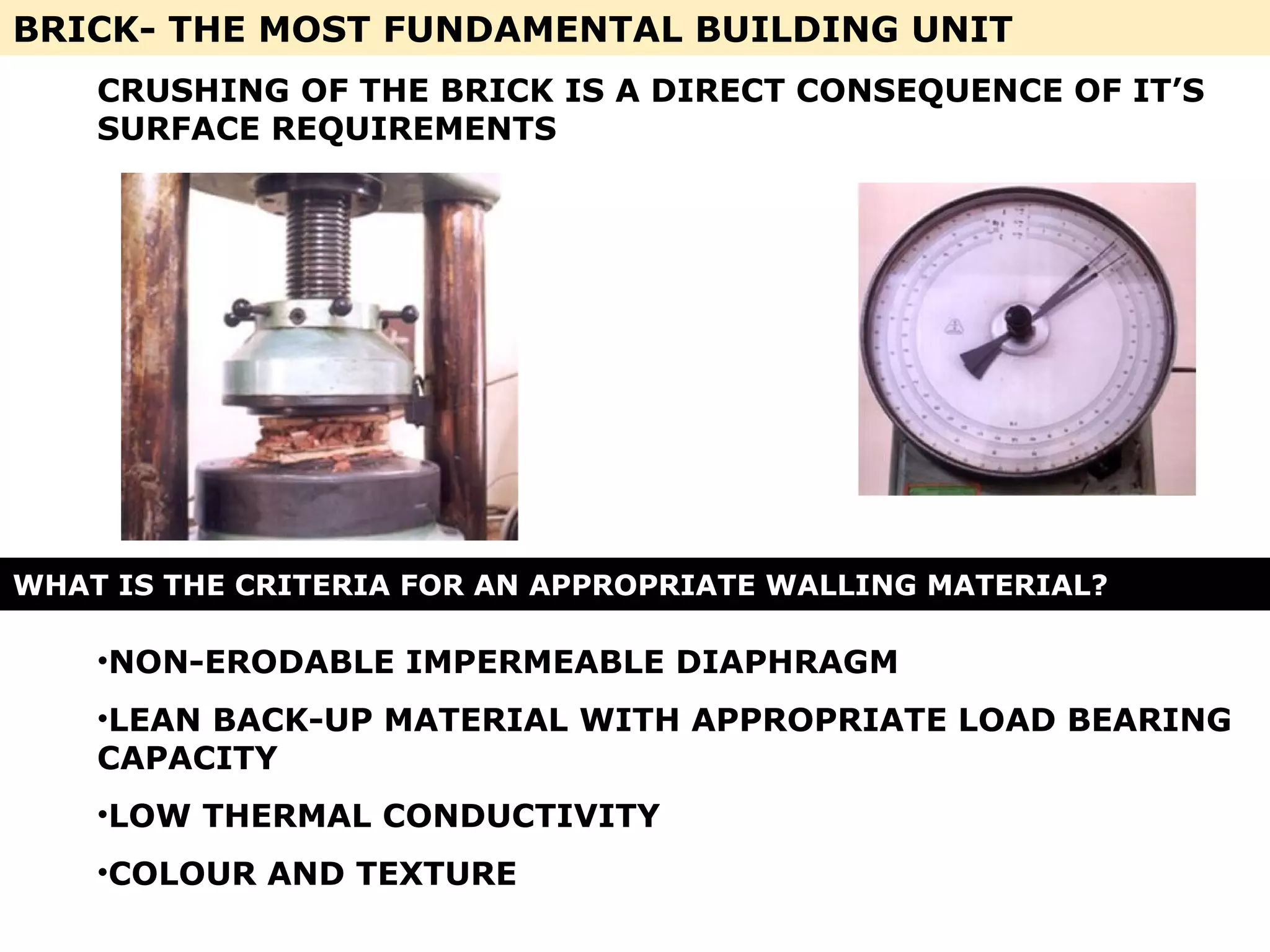

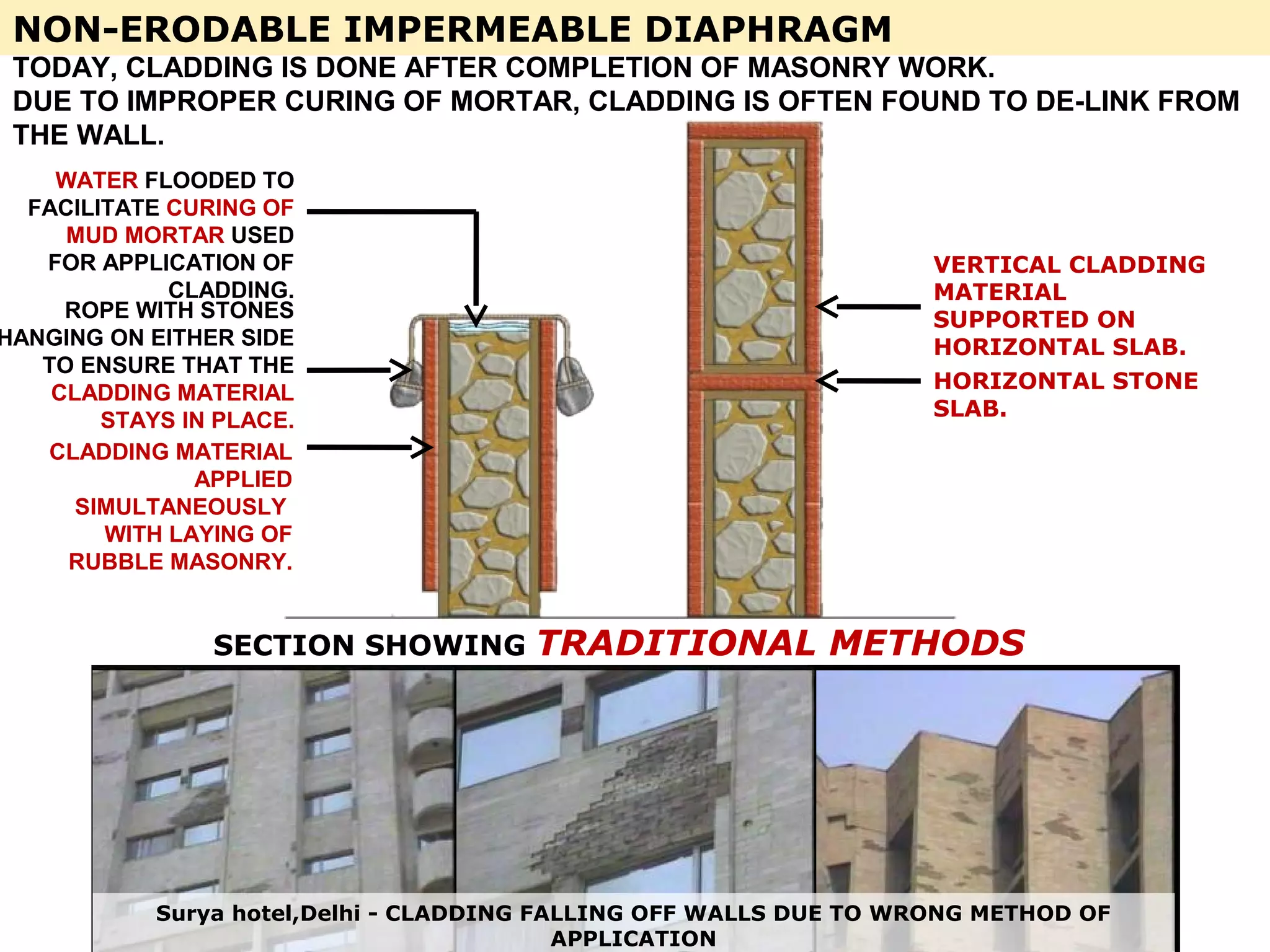

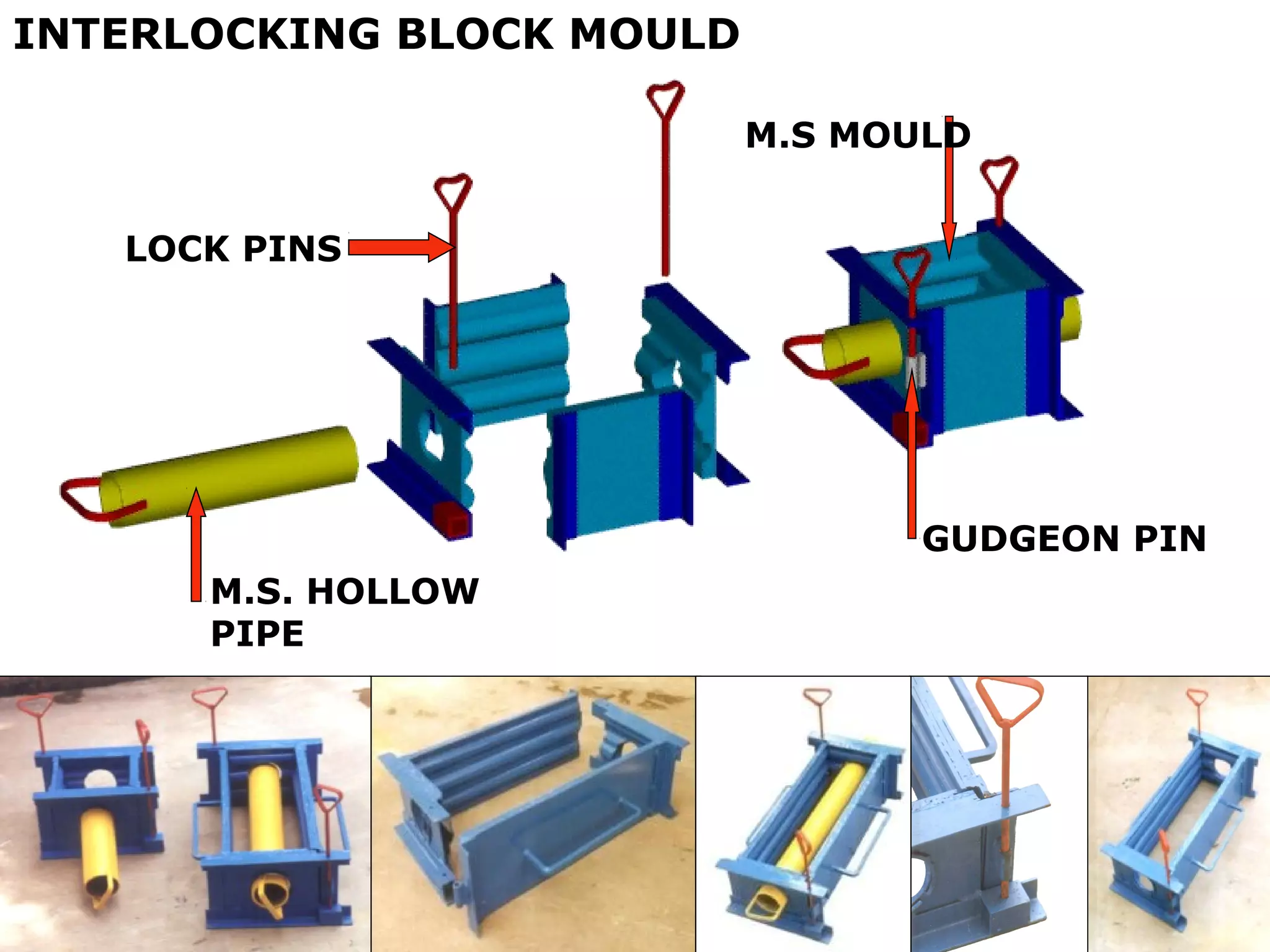

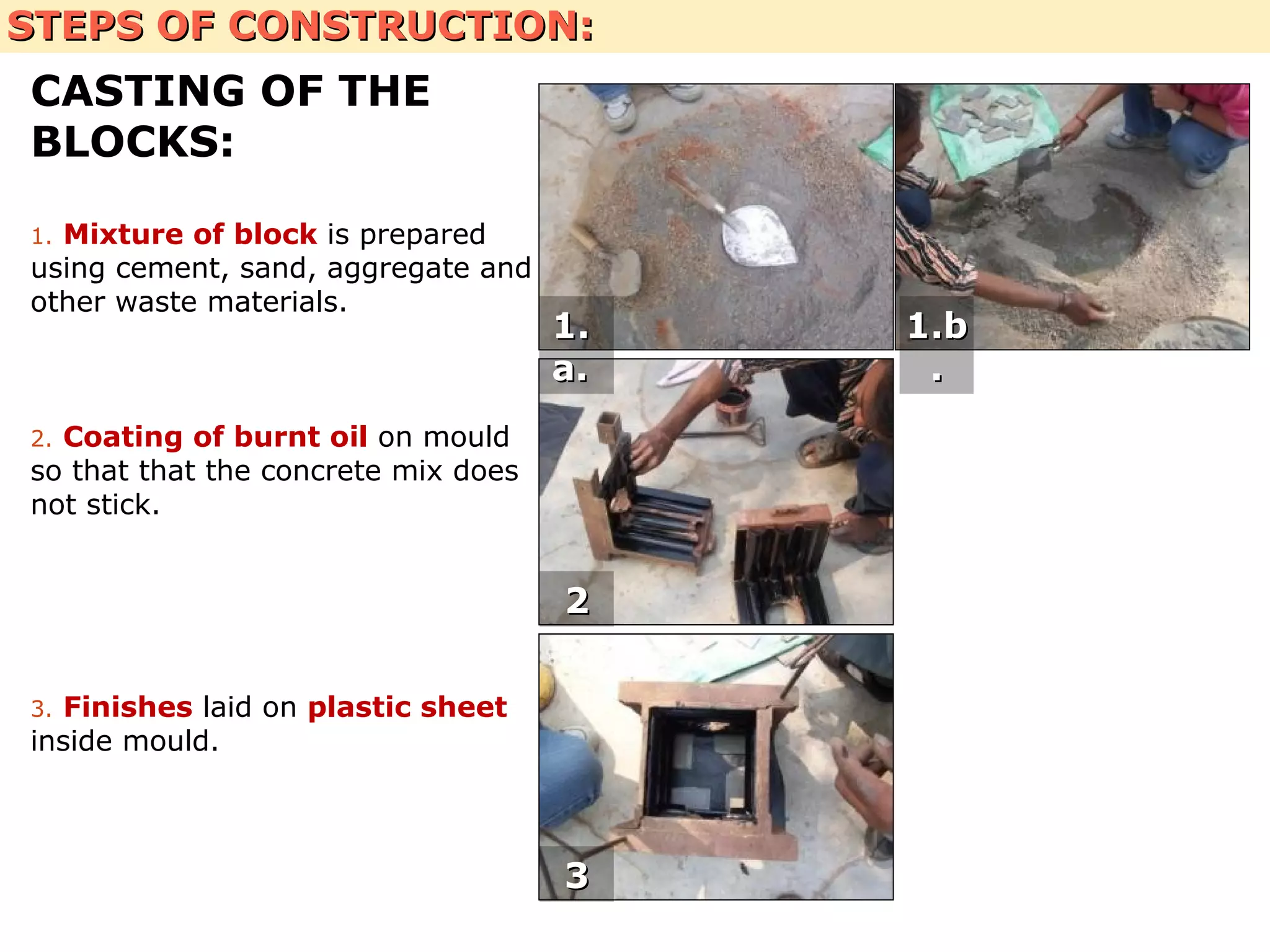

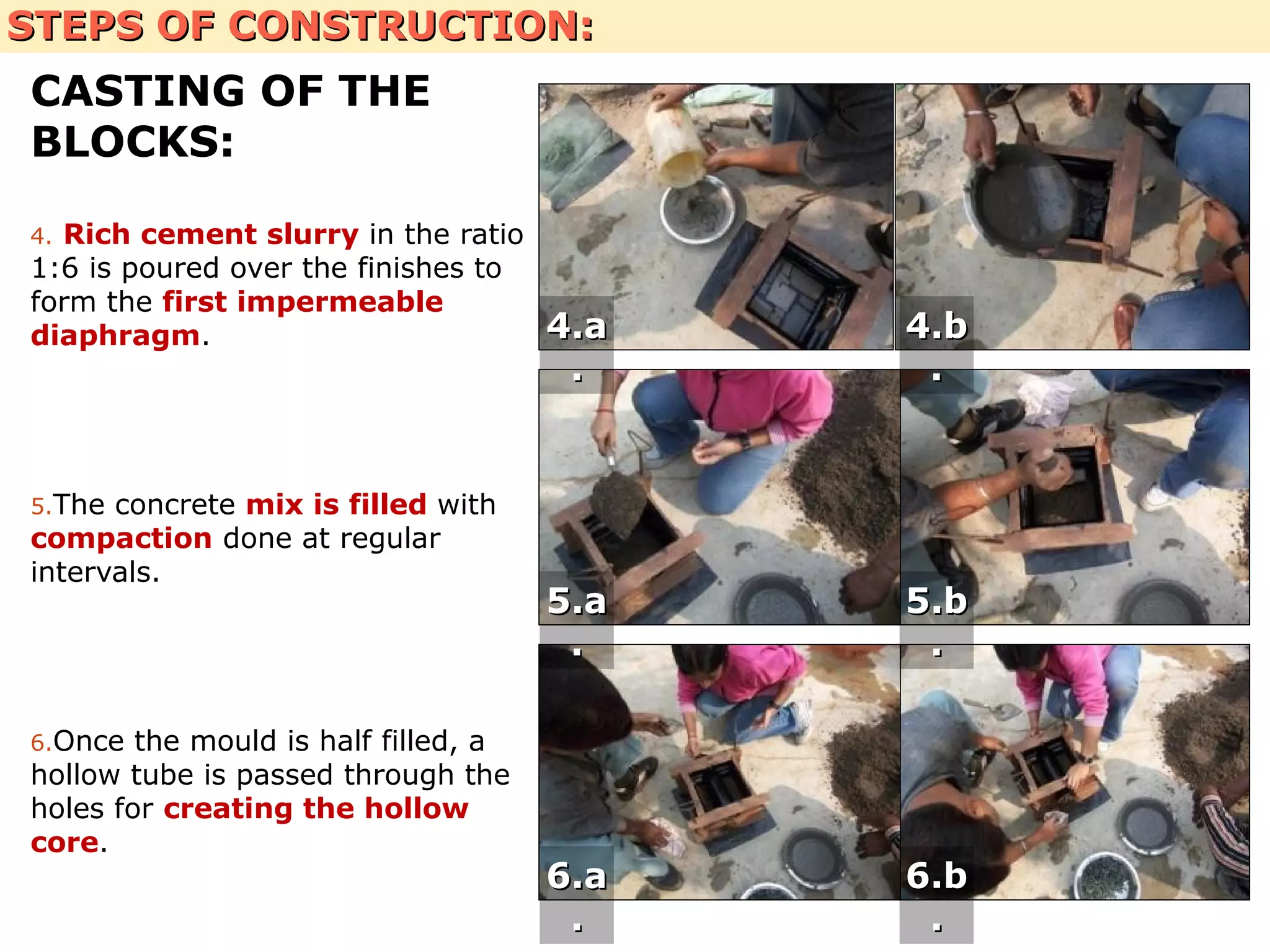

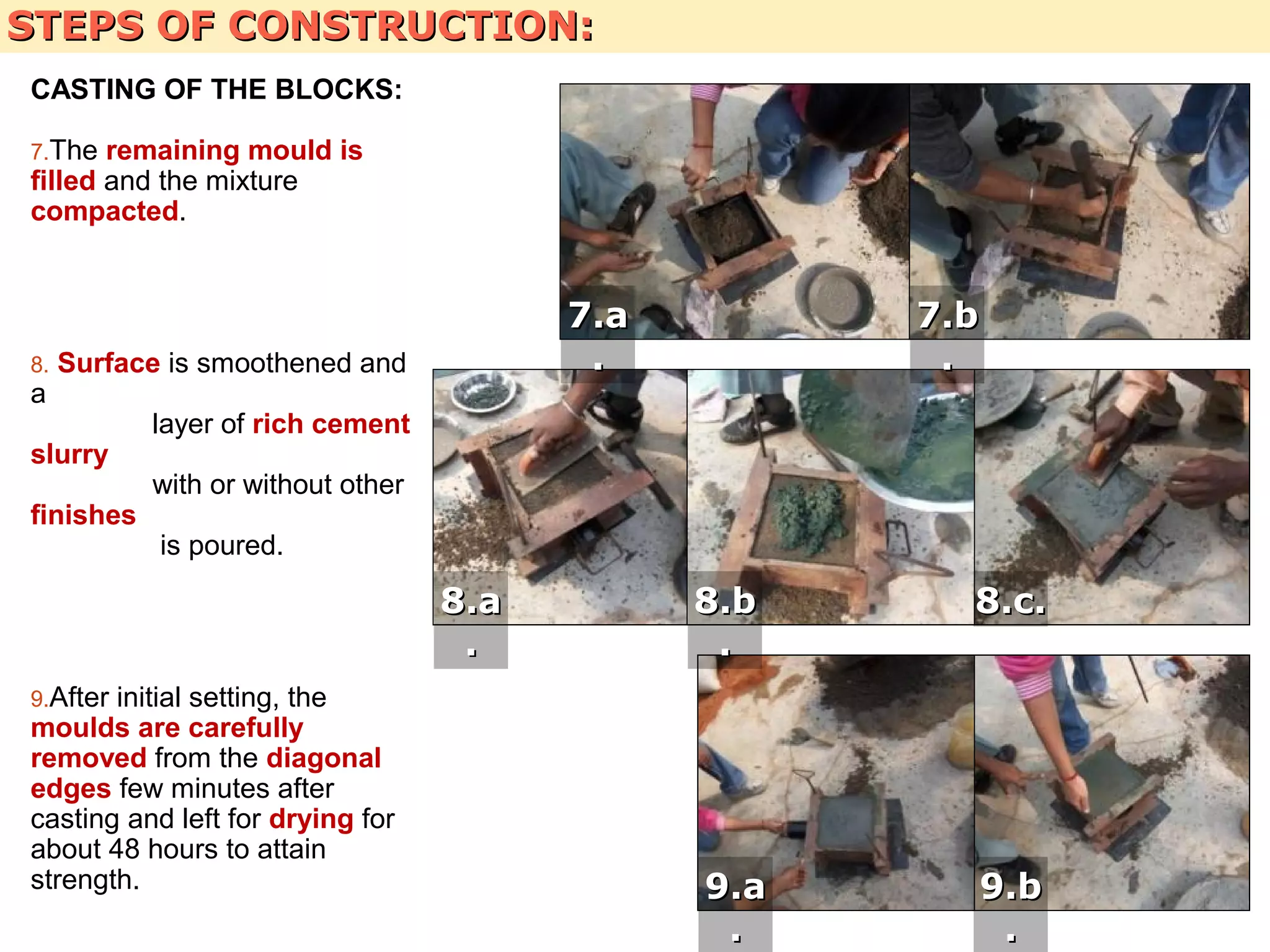

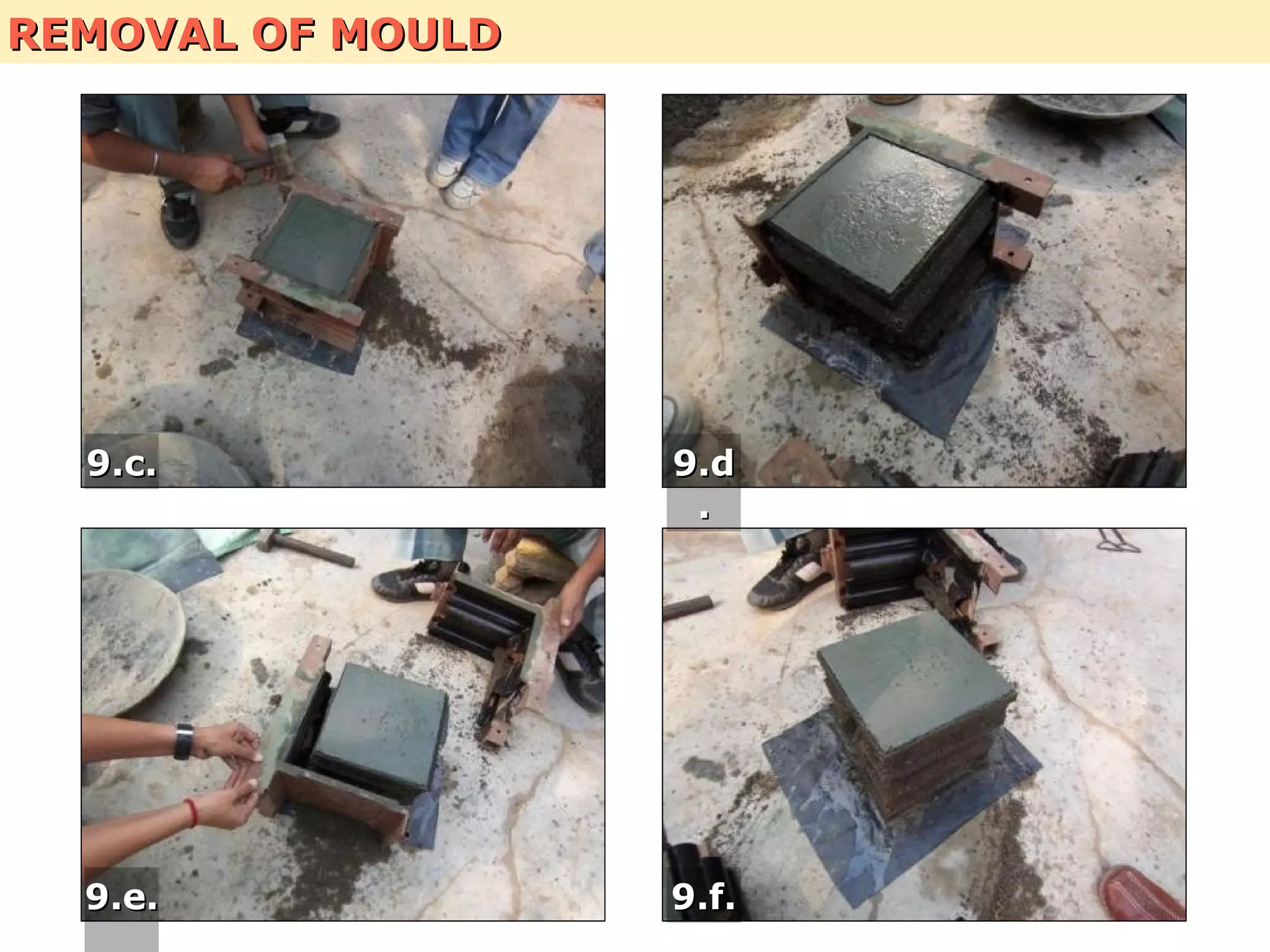

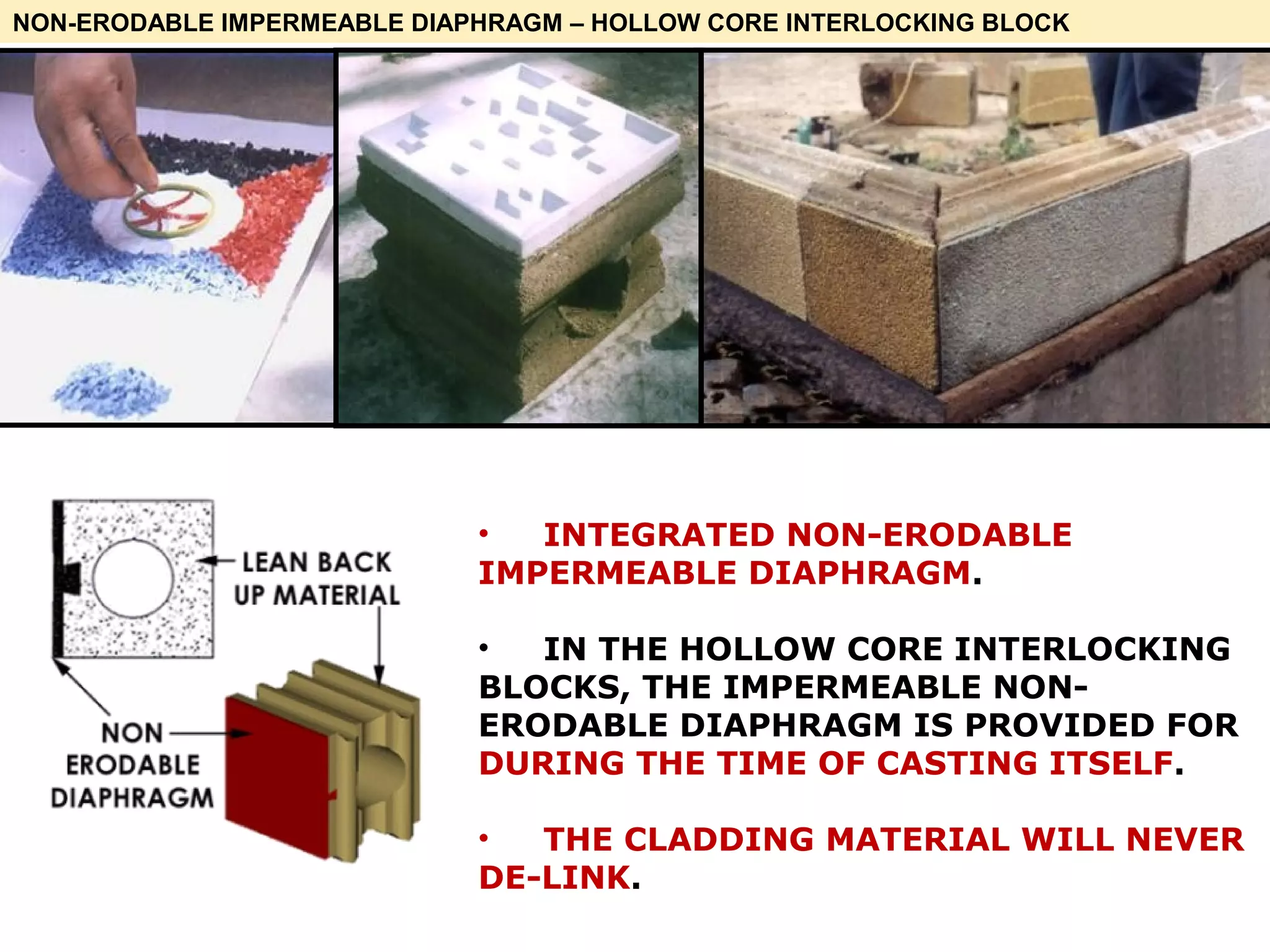

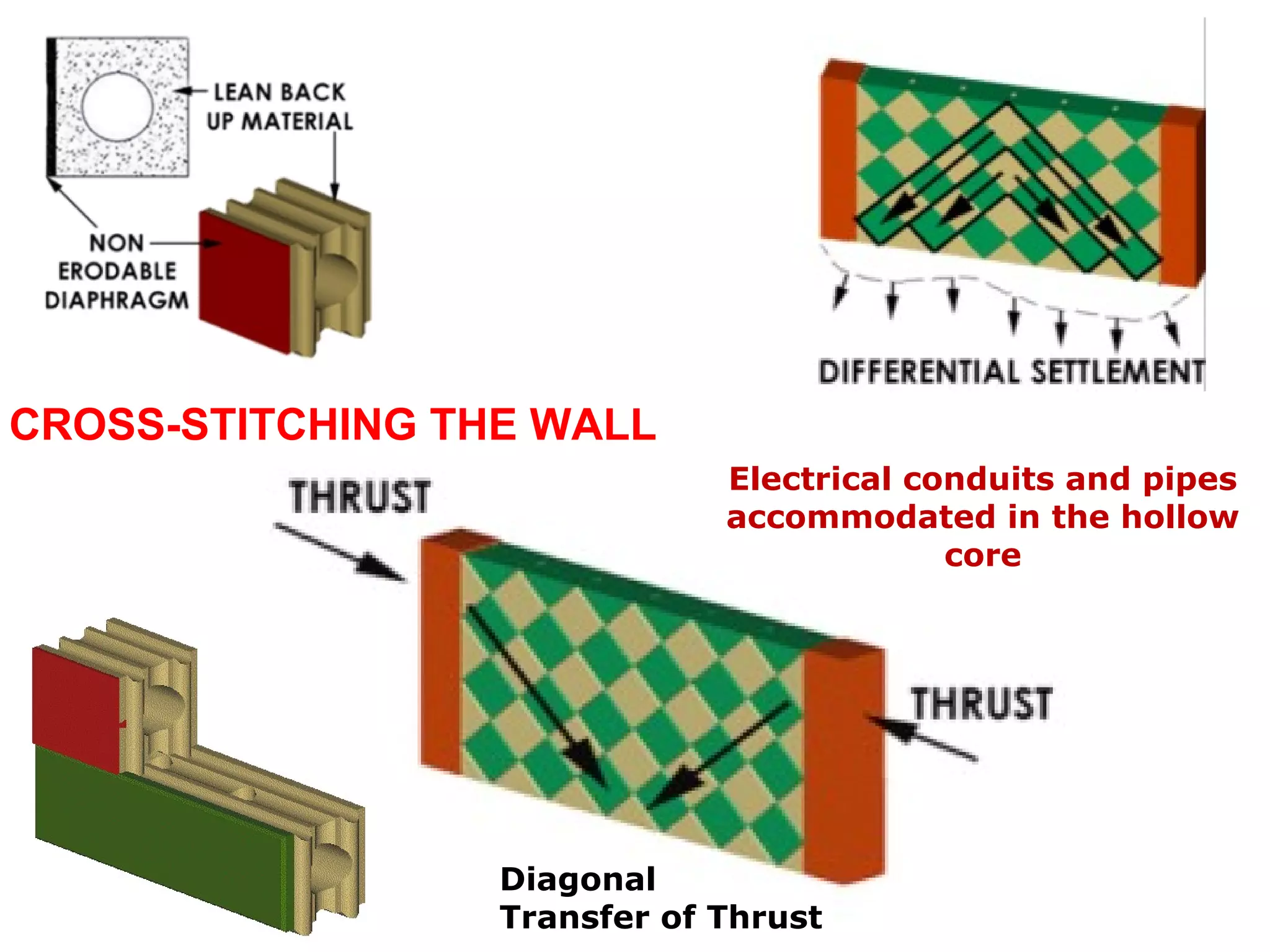

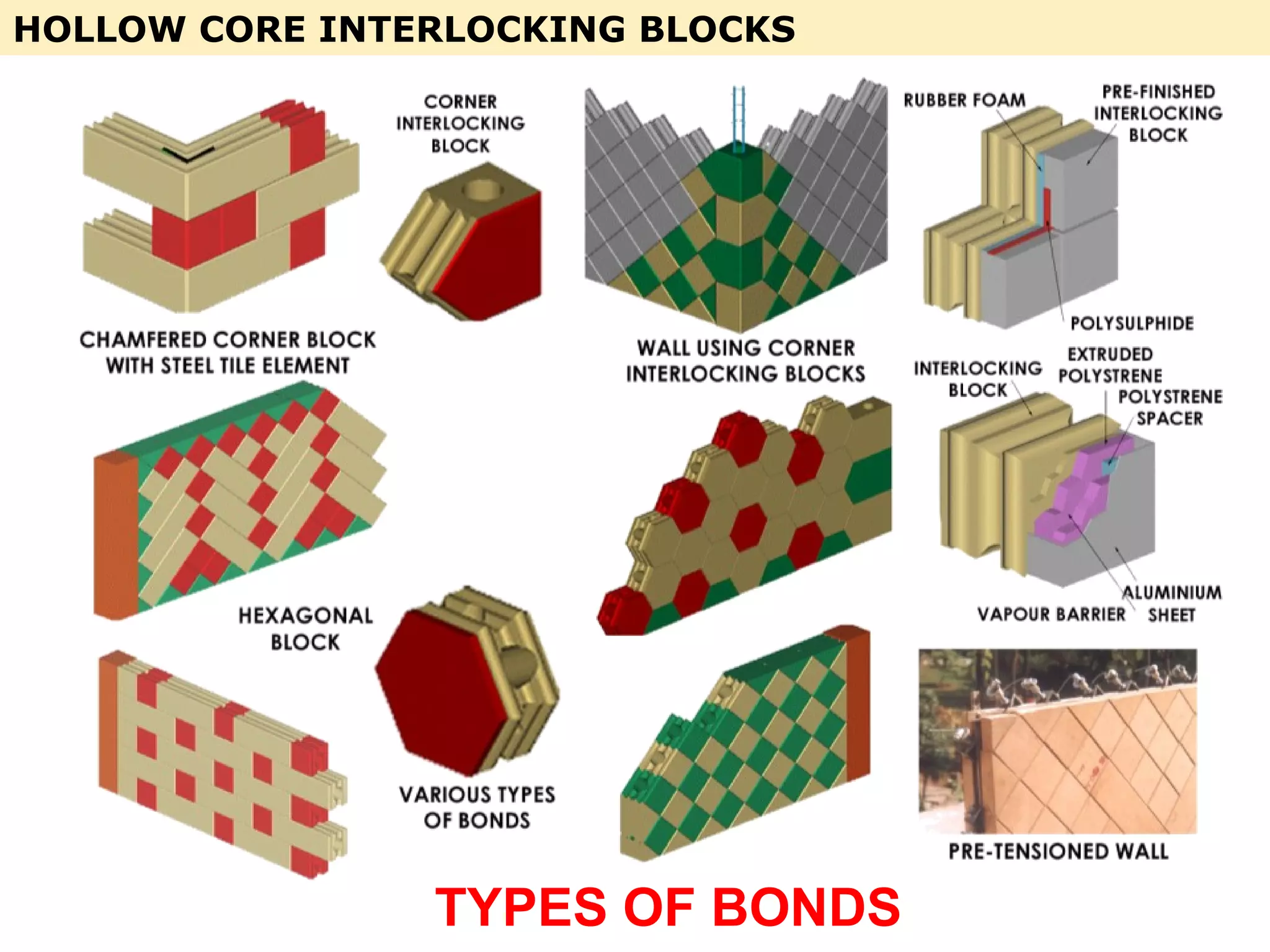

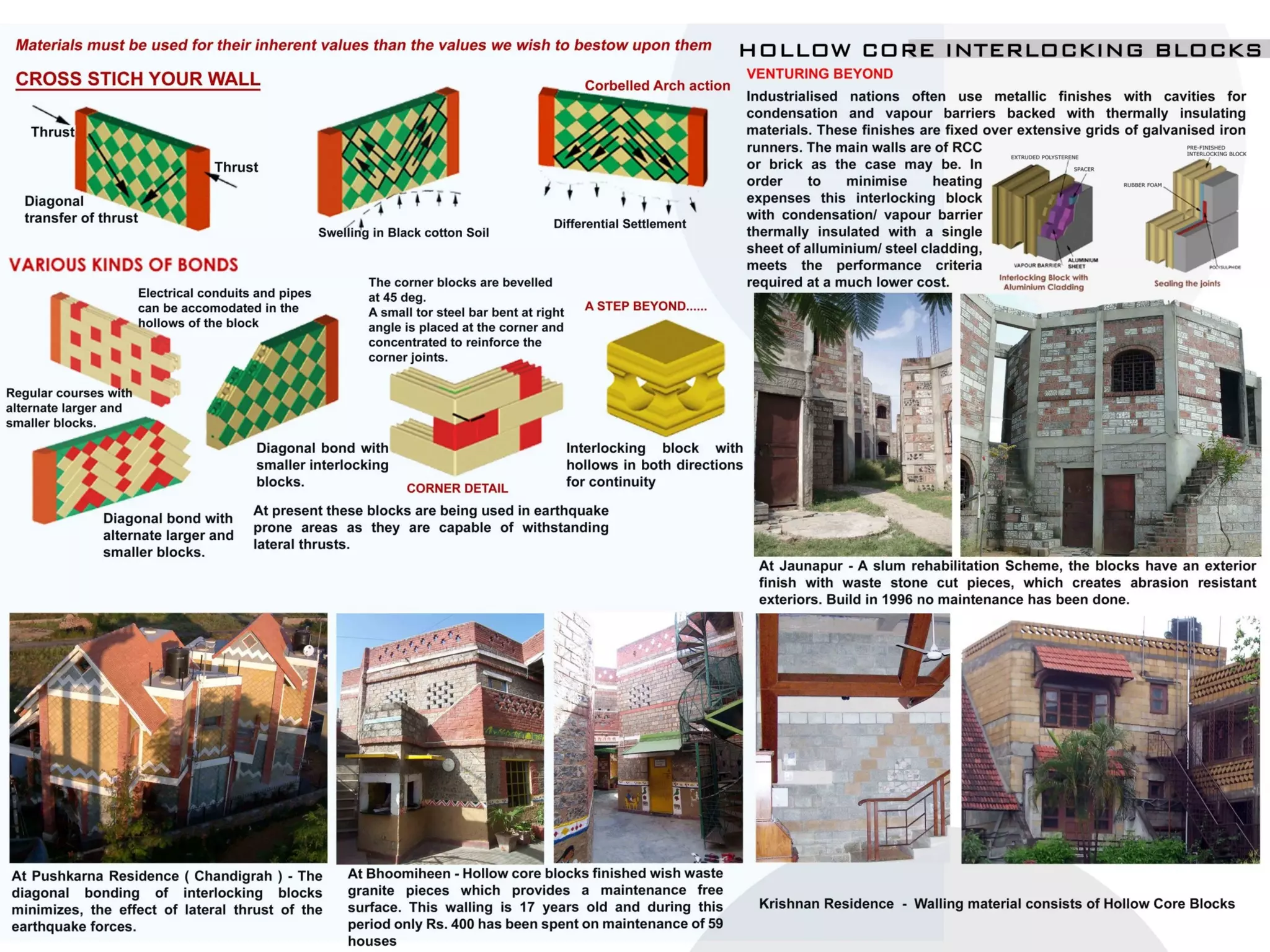

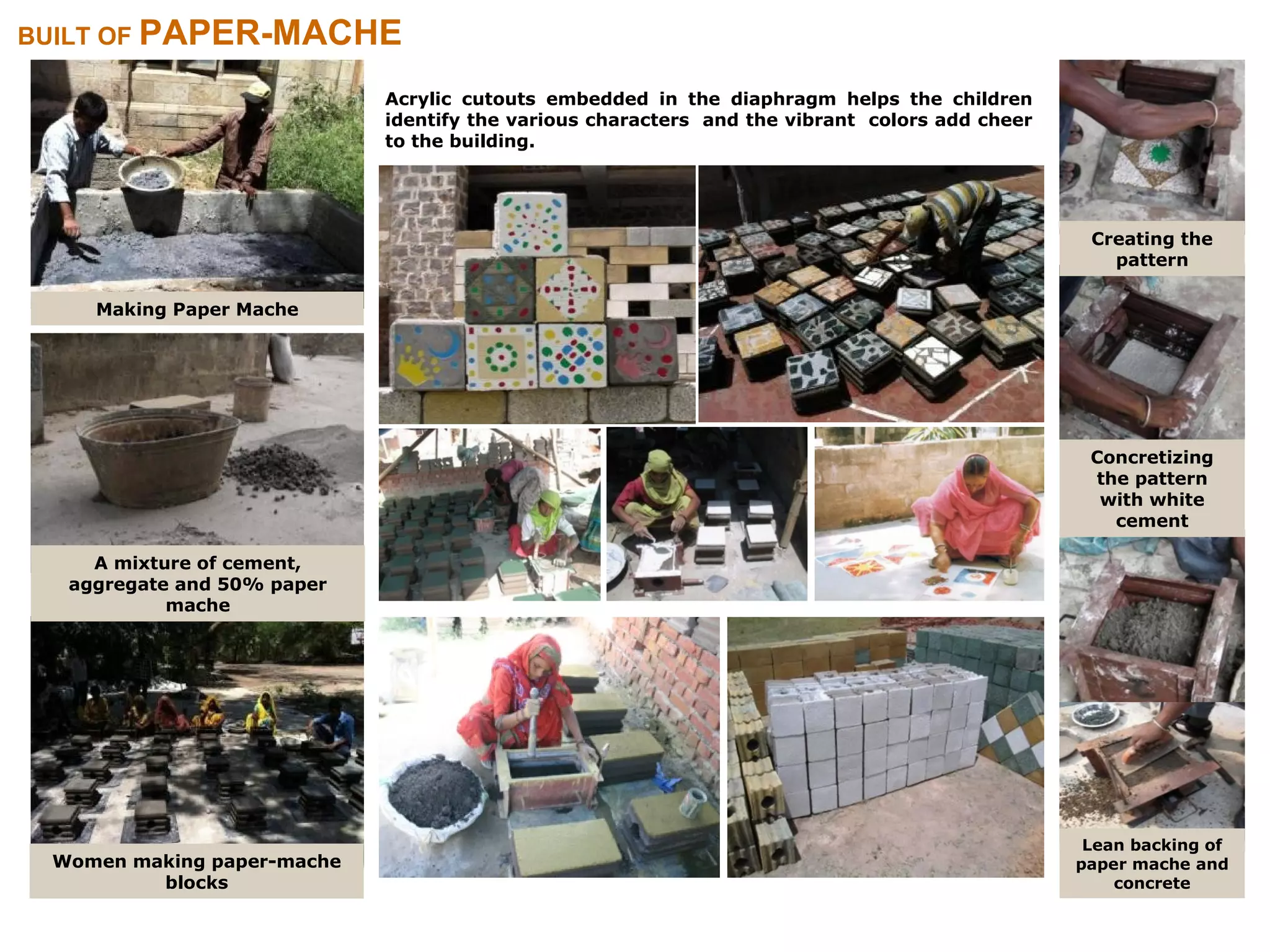

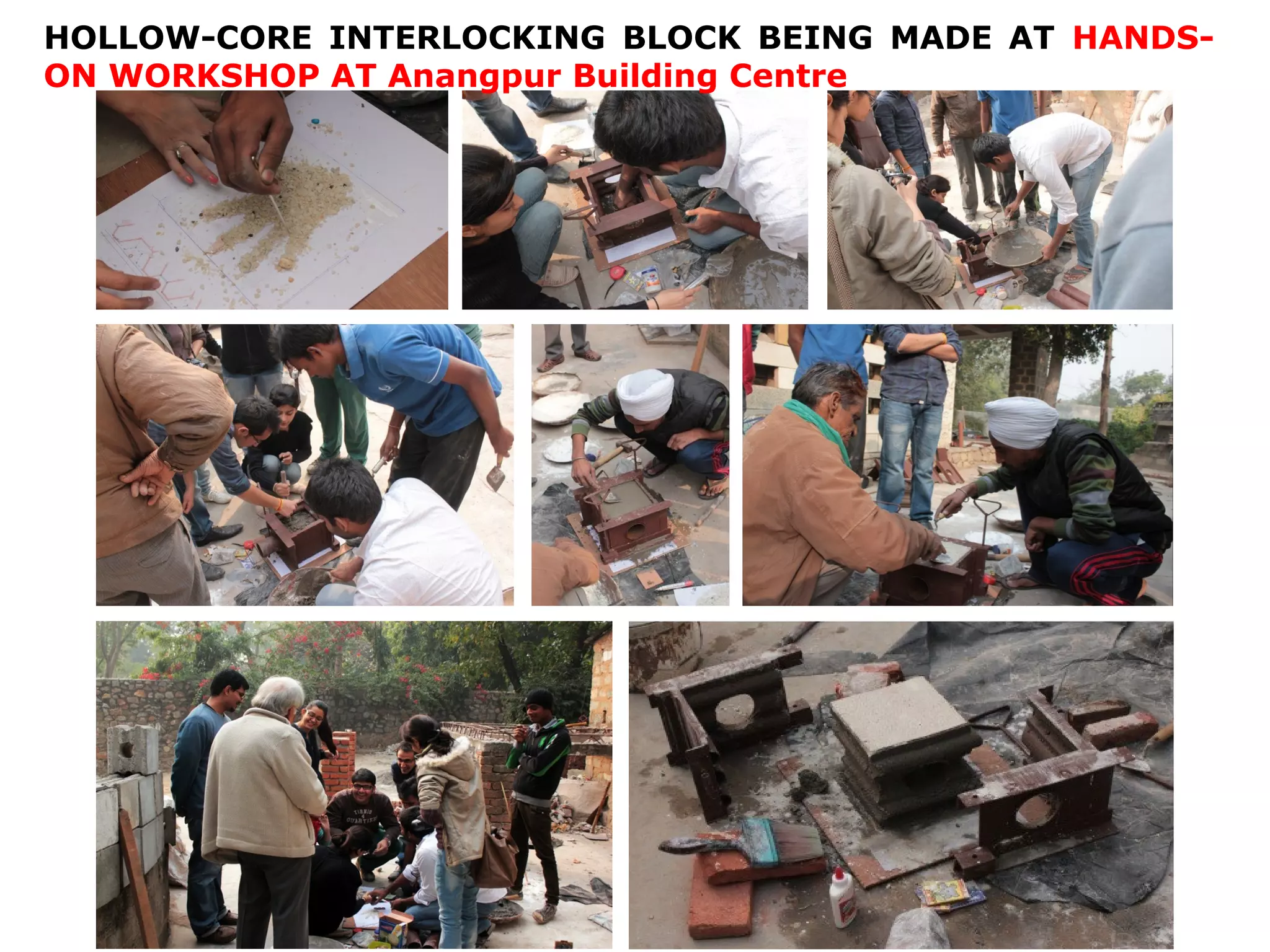

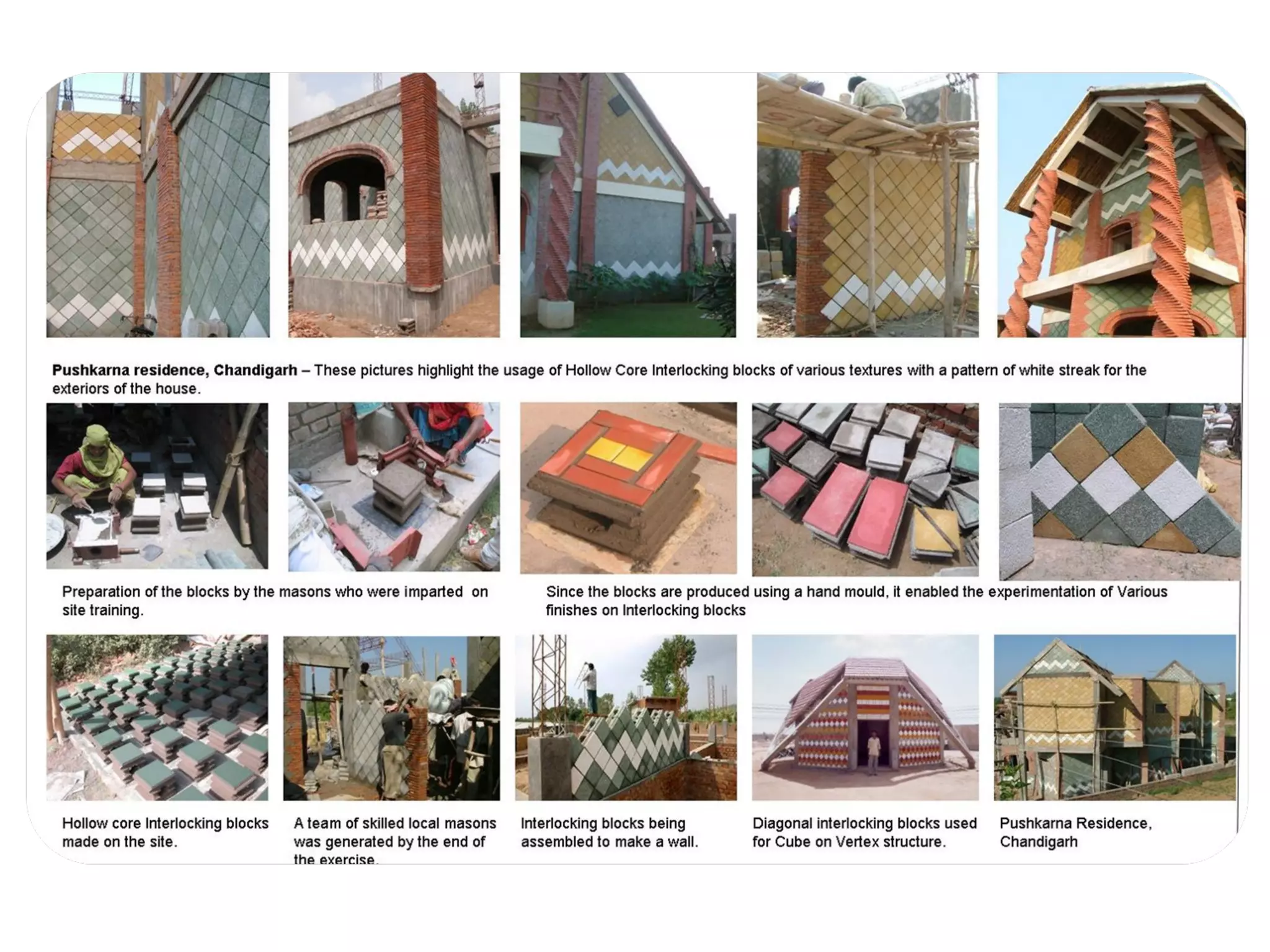

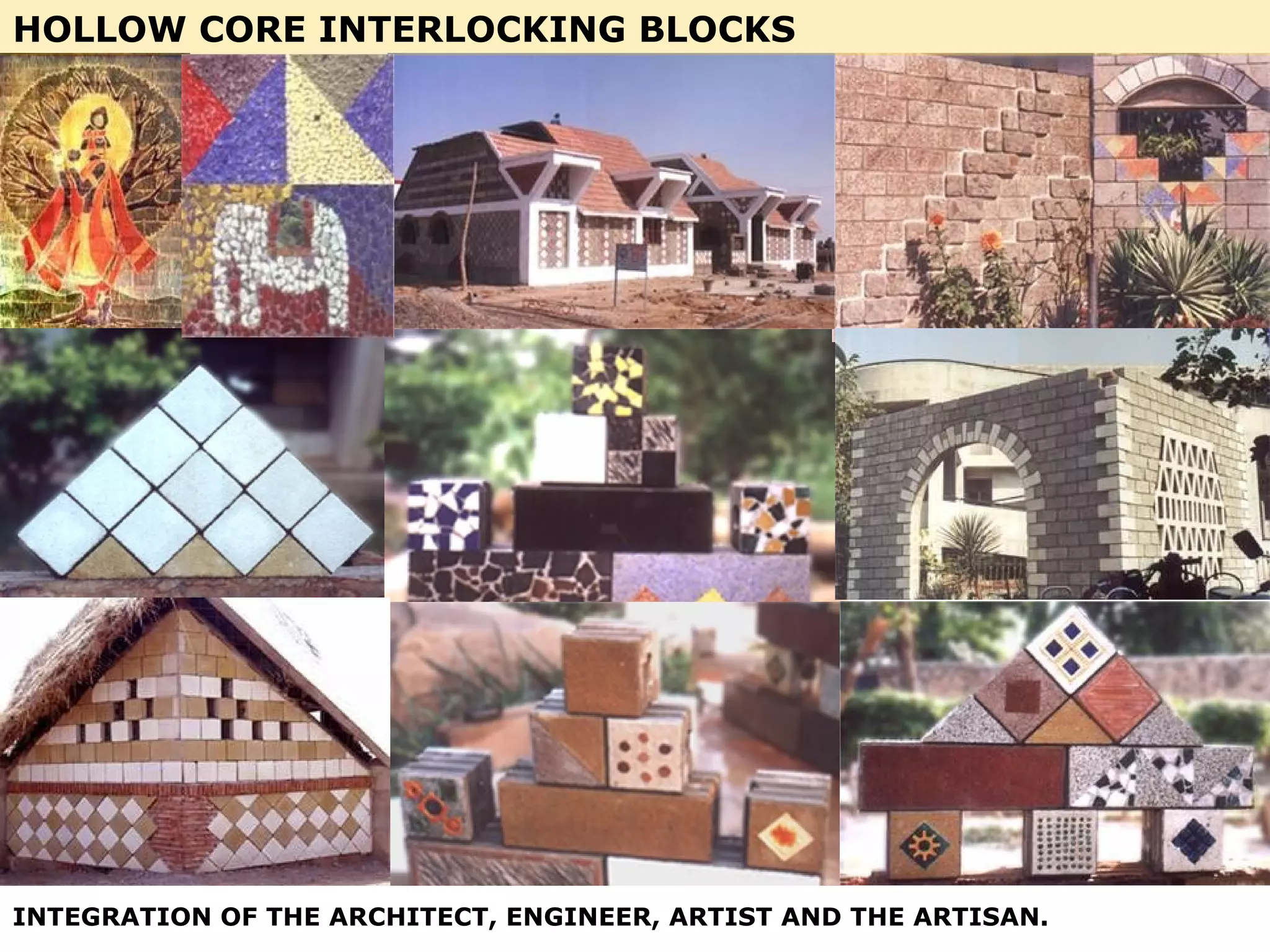

The document discusses the construction and benefits of hollow core interlocking blocks, emphasizing their role as an appropriate walling material that prevents issues like cladding de-linking. It details the step-by-step process of casting these blocks, including the use of waste materials for better thermal insulation. The text highlights the collaboration of architects, engineers, artists, and artisans in creating innovative and cost-effective construction solutions.